Automatic cutter-free rotary fruit picker and control method thereof

A rotary picking machine technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of reducing work efficiency, not being very useful overall, and inconvenient operation, so as to reduce the weight of the device and increase the reliability. Compatibility, ease of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

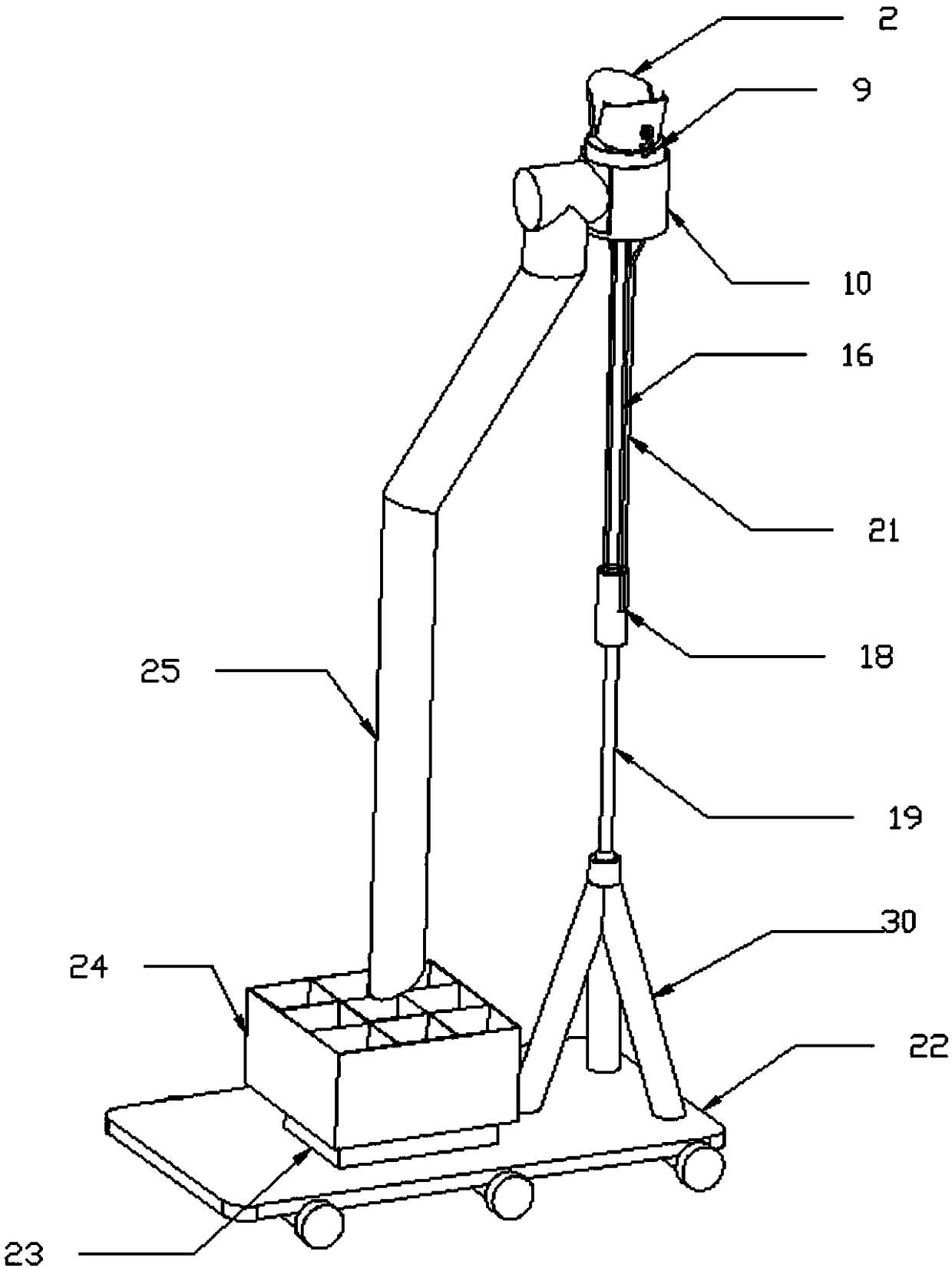

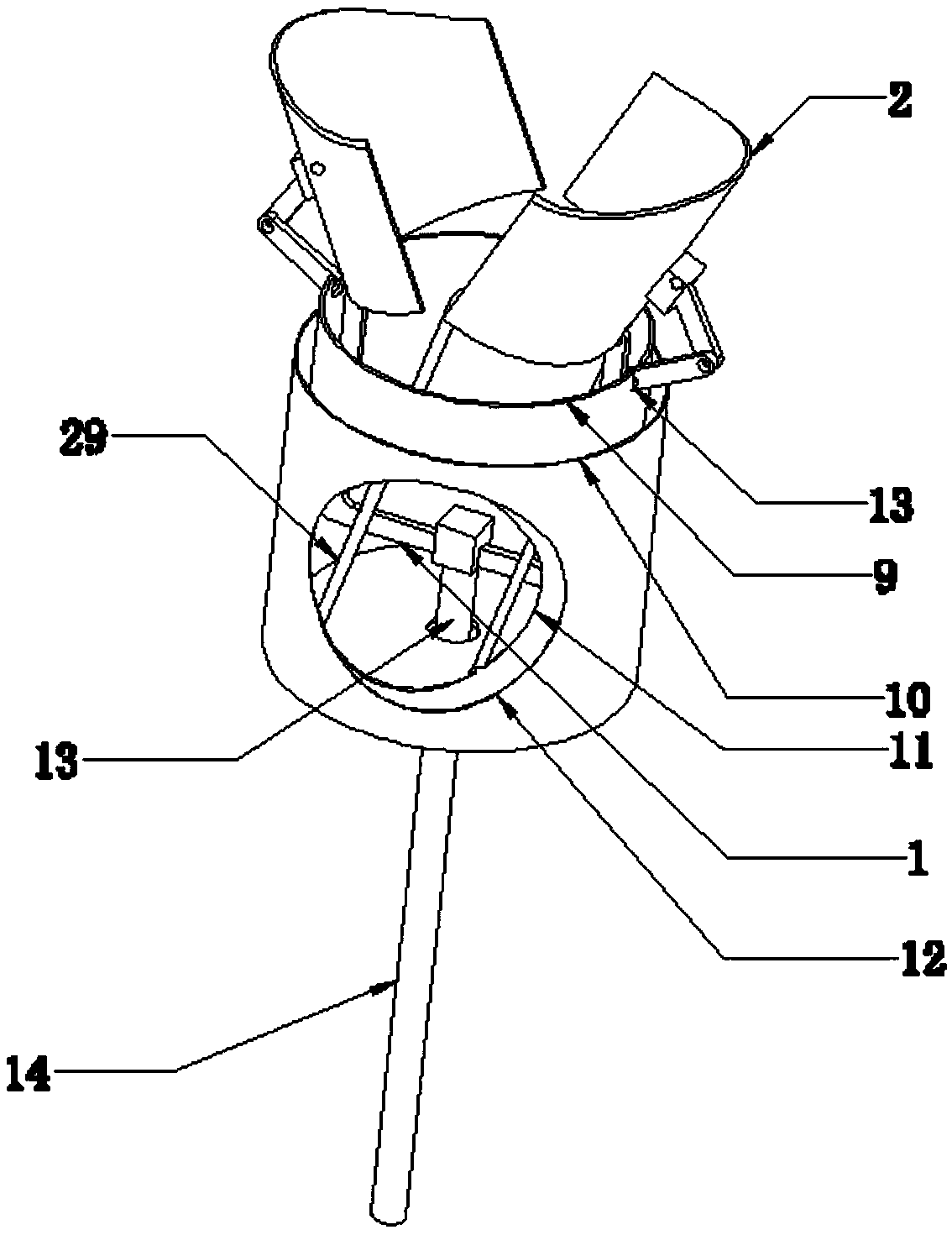

[0045] An automated knifeless rotary fruit picking machine, comprising a clamping mechanism, a rotating telescopic mechanism, a locking mechanism and a collecting mechanism for locking the clamping mechanism;

[0046] The clamping mechanism includes an inner tube 9 and an outer tube 10 arranged coaxially, a U-shaped frame 1 that is driven to move up and down arranged in the inner tube 9 and two symmetrically arranged U-shaped frames 1 Two gripping pieces 2 for gripping fruits at the top of the stand arm, the bottom of each gripping piece 2 is rotatably arranged on the corresponding stand arm through a four-link structure, and the bottom of the U-shaped frame 1 is fixedly arranged with one Drive rod 13, the bottom end of said drive rod 13 penetrates from the bottom of the inner tube 9 and the outer tube 10, and the inner tube 9 and the outer tube 10 are provided with fruits at positions corresponding to the circumferential side walls. The inner opening 11 and the outer opening 12 ...

Embodiment 2

[0067] In this embodiment, on the basis of Embodiment 1, the clamping mechanism is further optimized.

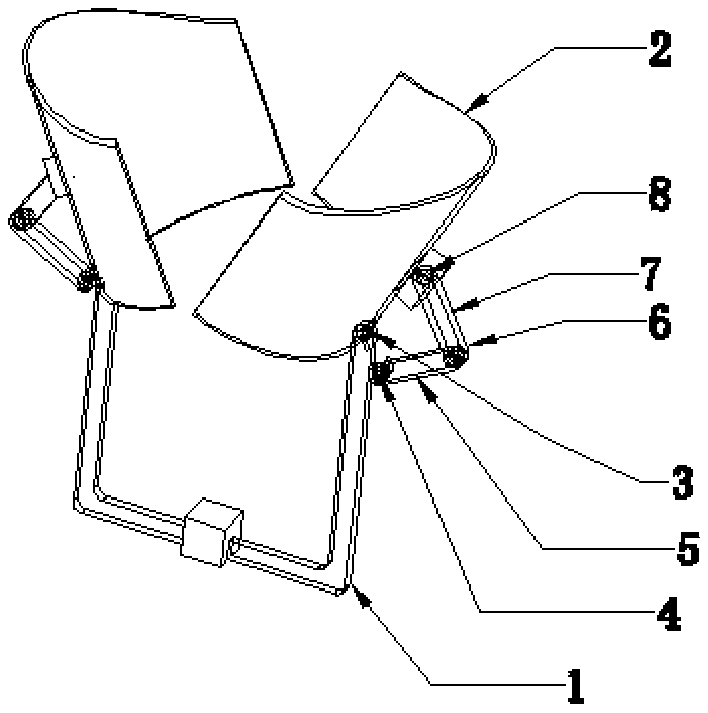

[0068] As a preferred manner, the bottom of the clamping piece 2 is rotatably connected to the top end of the U-shaped frame 1 through a first rotating shaft 3, and the middle and upper part of the U-shaped frame 1 is rotatably connected to one end of the lower link 5 through a second rotating shaft 4 , The other end of the lower link 5 is rotatably connected to one end of the upper link 7 through the third rotating shaft 6, and the other end of the upper link 7 is connected to the outer side wall of the clamping piece 2 through the fourth rotating shaft 8. The middle part is rotatably connected, and the top edge of the inner cylinder 9 is formed with a notch 13 for supporting the lower link 5.

[0069] The middle and upper part of the U-shaped frame 1, the lower connecting rod 5, the upper connecting rod 7, and the middle to the bottom section of the clamping piece 2 are combine...

Embodiment 3

[0074] In this embodiment, on the basis of Embodiment 1, the locking mechanism is optimized.

[0075] An iron hook is fixed at the end of the drawstring, and a plurality of holes for fixing the iron hook are opened at different heights of the handle bar 18. When the fruit is clamped, the iron hook is pulled down by hand. When the clamping device fixes the fruit, the iron hook is fixed in the small hole to realize the locking of the clamping device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com