High-power permanent magnet motor rotor structure

A permanent magnet motor and rotor structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, magnetic circuit, etc., to achieve high reliability, reduce moment of inertia, and save the effect of installation tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

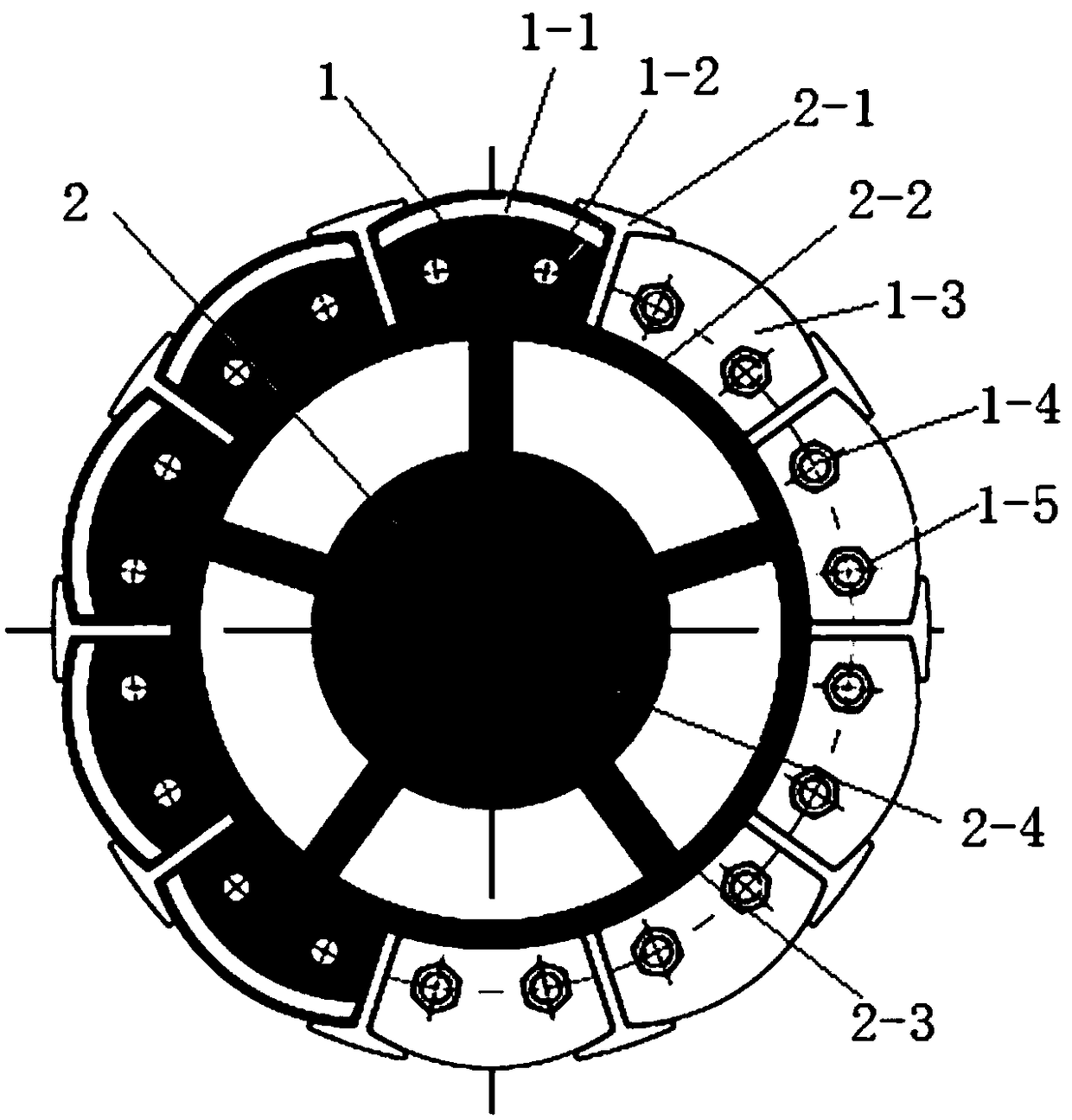

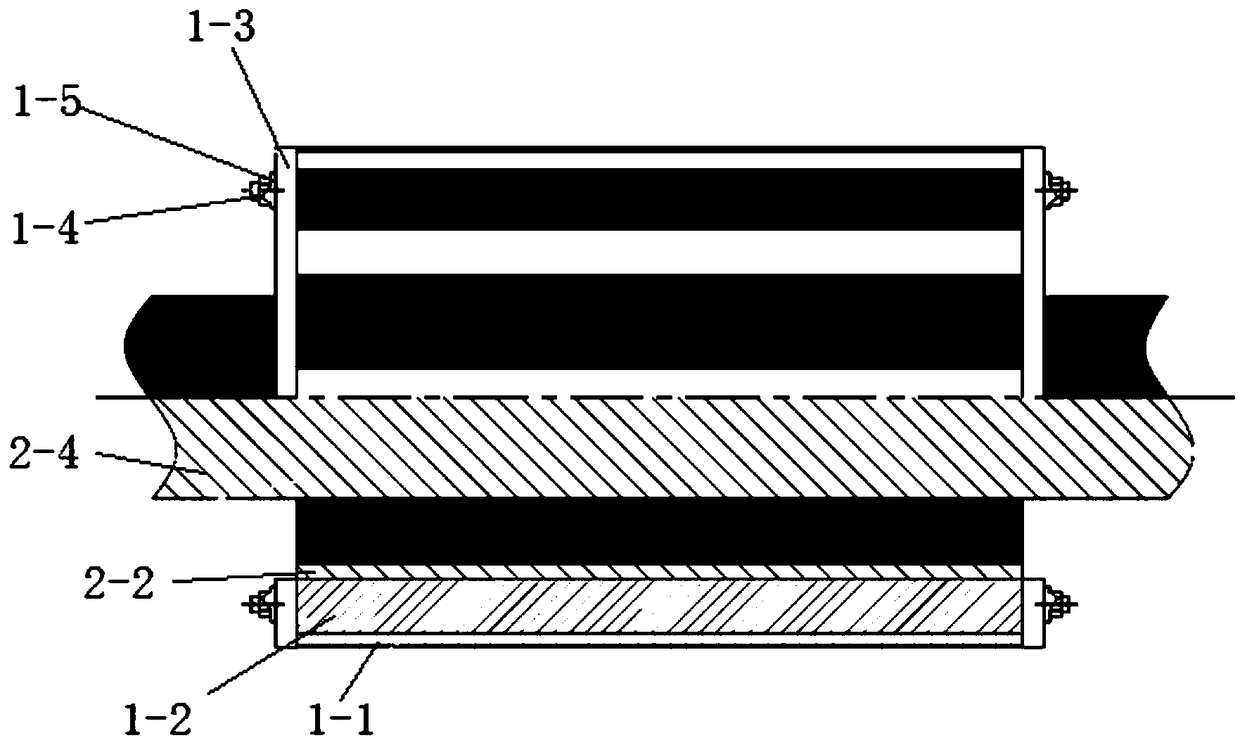

[0022] like figure 1 and figure 2 As shown, the rotor structure of the high-power permanent magnet motor of the present invention includes: a magnetic pole structure 1 and a rotating shaft structure 2; the magnetic pole structure 1 includes: a permanent magnet 1-1, a magnetic pole box 1-2, a pressing plate 1-3, and a pull rod 1-4 , nuts and washers 1-5; the rotating shaft structure 2 includes: a titanium alloy rib plate 2-1, a cylinder 2-2, a supporting rib 2-3, and a rotating shaft 2-4.

[0023] The magnetic pole box 1-2 is made of silicon steel sheets with punching grooves and the pressure plate 1-3 glued and laminated. After evenly applying resin glue on the surface of each silicon steel sheet, stack it with two pressing plates 1-3. The pressing plates 1-3 have the same size as the silicon steel sheet and are placed at both ends. Use two pull rods 1-4 with threads at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com