One-Step Preparation of Polyaniline-TiO2 Nanotube Array Composite Electrode

A technology of nanotube array and titanium dioxide, which is applied in the field of electrochemistry, can solve the problems of weak binding force, excessive waste liquid, and small diameter of nanotubes, and achieve the effects of improving bonding strength, simplifying process steps, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Mix 20 g of ethanol, 10 g of water and 70 g of ethylene glycol, add 0.3 g of ammonium fluoride, 3 g of aniline and 3 g of concentrated sulfuric acid (98% by mass, the same as in the following examples), stir and dissolve to obtain a mixed solution. The mixed solution is used as the electrolyte, the metal titanium sheet (99% of purity) is used as the anode, the platinum sheet (99.99% of the purity) is used as the cathode, the distance between the anode and the cathode is 2cm, and the anodic oxidation is carried out at 5°C and 40V for 3 Hour. After the reaction is finished, the electrolyzed anode sheet is washed with deionized water and dried to obtain the polyaniline-titanium dioxide nanotube array composite electrode.

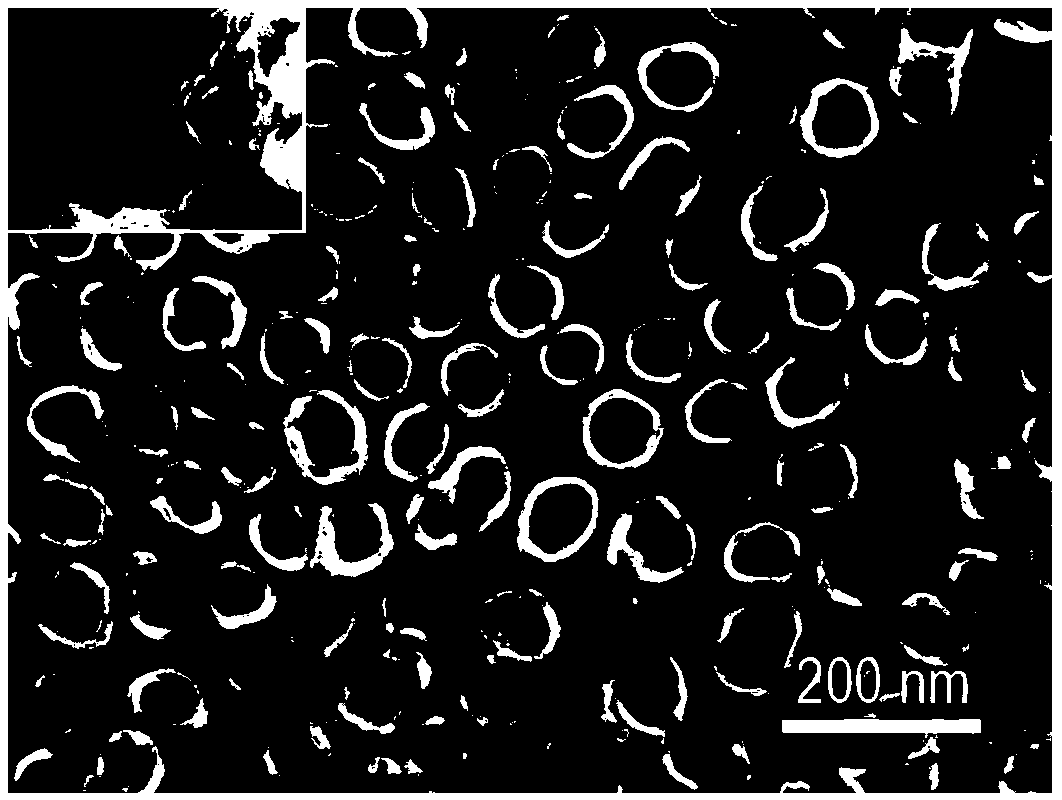

[0024] Depend on figure 1 It can be seen that the prepared polyaniline-titanium dioxide nanotube array composite electrode is composed of titanium dioxide and polyaniline. On the tube wall of the tube, the two are tightly combined.

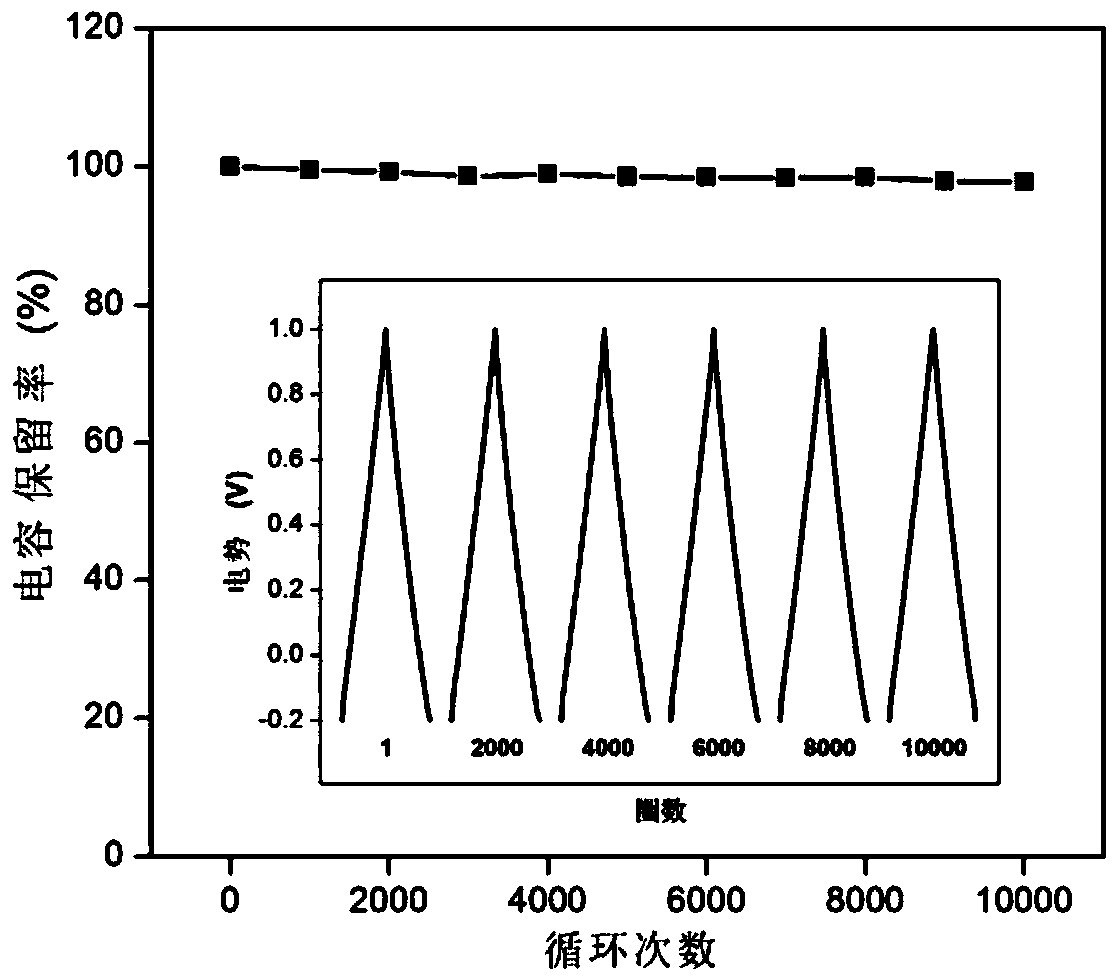

[0025] The electr...

Embodiment 2

[0027] Mix 10g of ethanol, 20g of water and 70g of ethylene glycol together, add 0.4g of ammonium fluoride, 2g of aniline and 2g of concentrated sulfuric acid, stir and dissolve to obtain a mixed solution. The mixed solution was used as the electrolyte, the metal titanium sheet was used as the anode, and the platinum sheet was used as the cathode. The distance between the anode and the cathode was 2 cm, and anodized at 3°C and 30V for 4 hours. After the reaction, the sample was washed with deionized water and dried to obtain a polyaniline-titanium dioxide nanotube array composite electrode, whose performance was similar to that of Example 1.

Embodiment 3

[0029] Mix 40g of ethanol, 1g of water and 59g of ethylene glycol together, add 0.5g of ammonium fluoride, 5g of aniline and 5g of concentrated sulfuric acid, stir and dissolve to obtain a mixed solution. Using this mixed solution as the electrolyte, the metal titanium sheet as the anode, and the platinum sheet as the cathode, the distance between the anode and the cathode is 2 cm, and anodized at 0°C and 50V for 1 hour. After the reaction, the sample was washed with deionized water and dried to obtain a polyaniline-titanium dioxide nanotube array composite electrode, whose performance was similar to that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com