A method for optimizing process parameter of plasma spray welding repair of a product

A technology for process parameter optimization and process parameter application in design optimization/simulation, electrical digital data processing, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

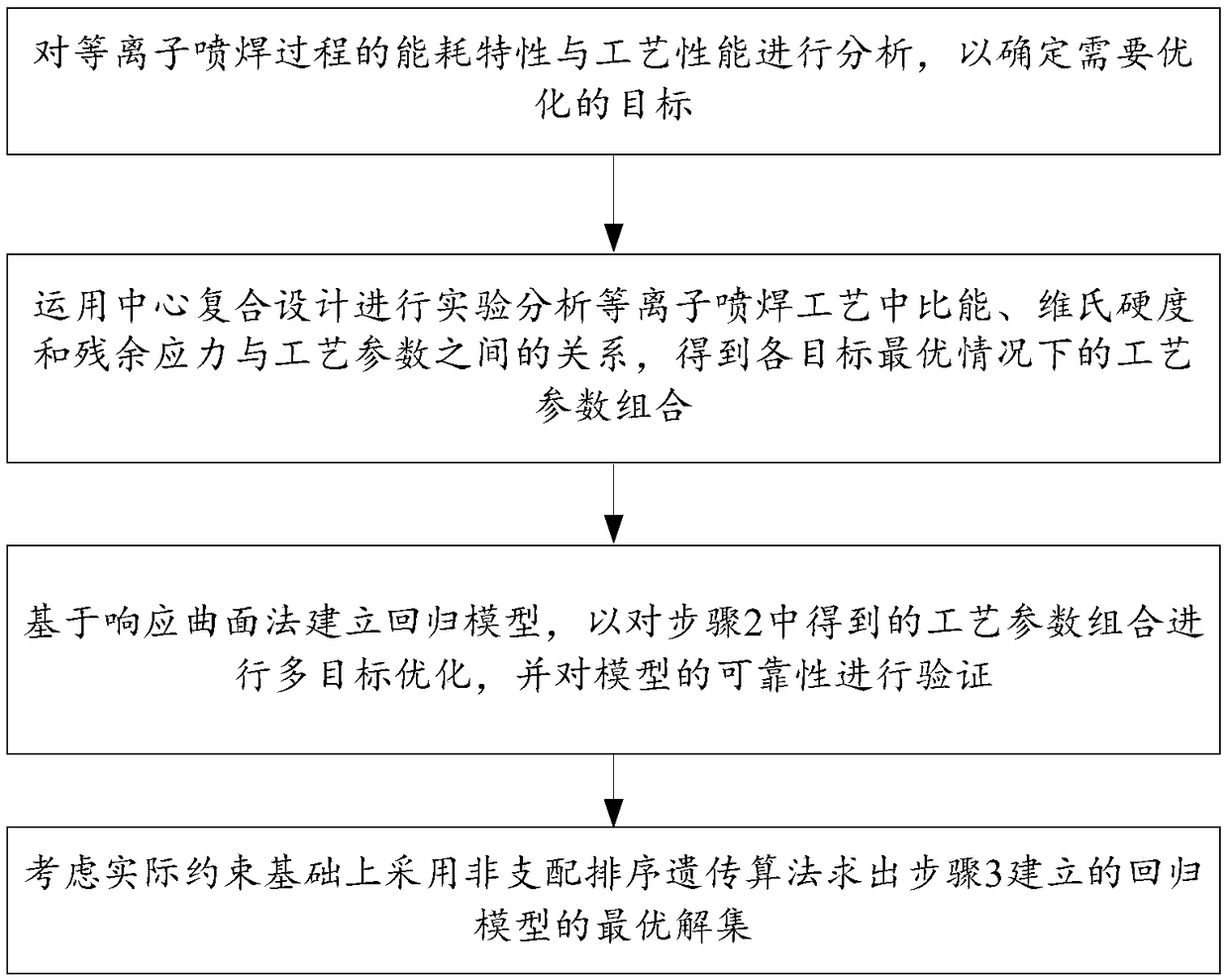

[0050] A method for optimizing product plasma spray welding repair process parameters for high energy efficiency and high process performance. Include the following steps:

[0051] Step 1. Analyze the energy consumption characteristics and process performance of the plasma spray welding process to determine the goals that need to be optimized. The goals include the specific energy function that characterizes the energy utilization rate of plasma spray welding, and the process performance that characterizes the plasma spray welding repair parts. Vickers hardness, residual stress in heat-affected zone;

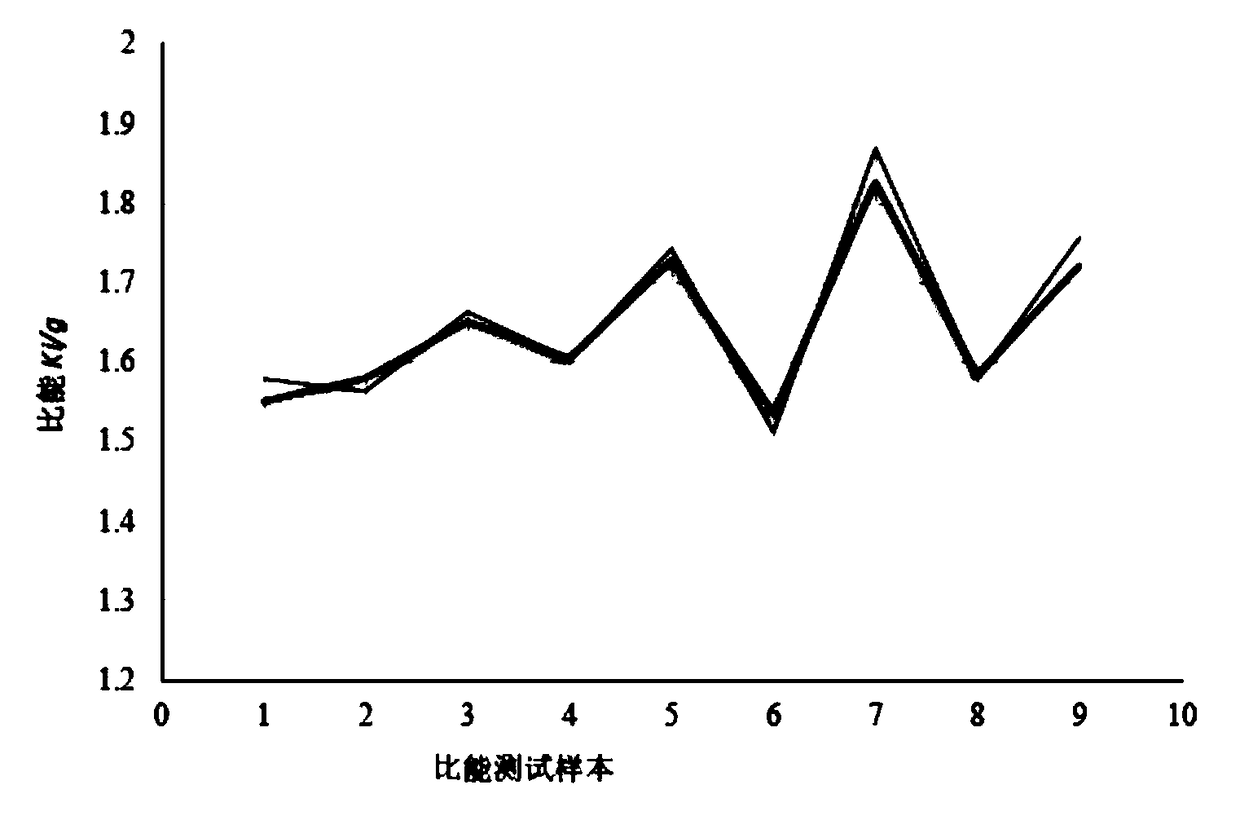

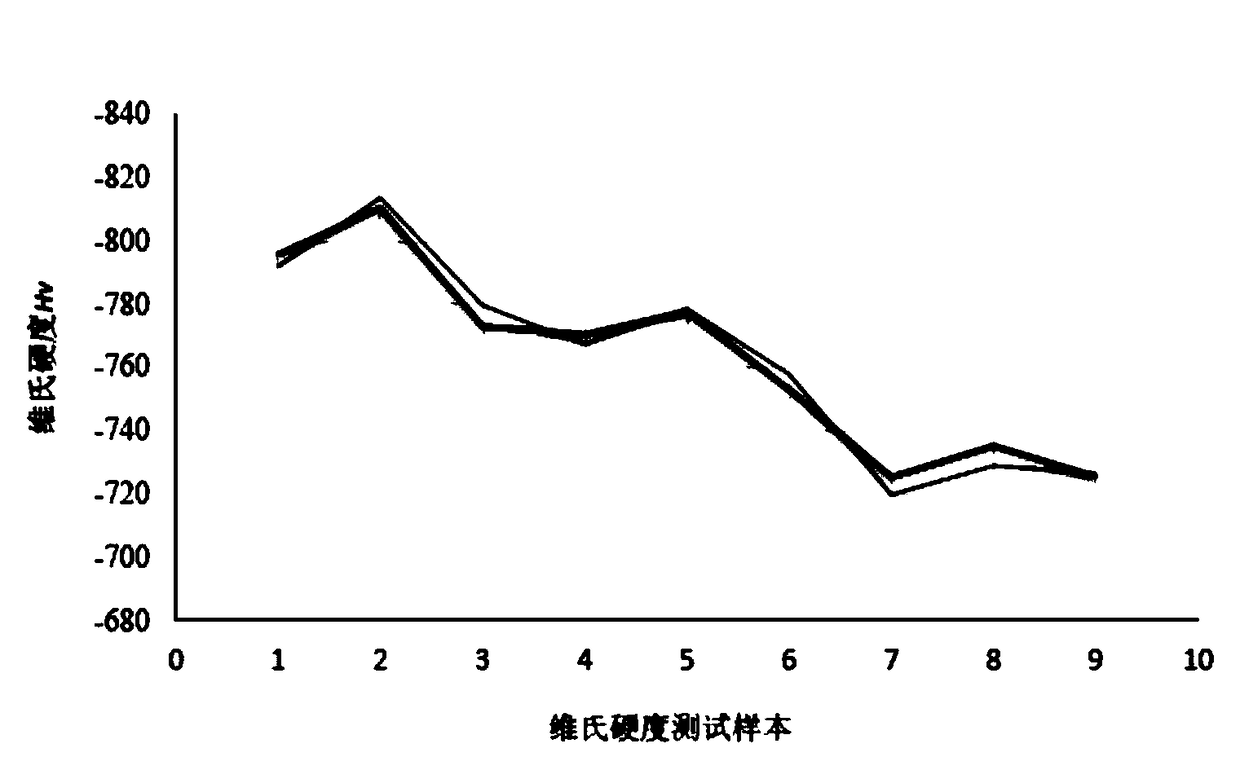

[0052] Step 2, using central composite design to conduct experiments to analyze the relationship between specific energy, Vickers hardness, residual stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com