Superlarge ball valve

A ball valve, extra large technology, applied in the valve device, cock including cut-off device, engine components, etc., can solve the problem of easy gap between the water pipe and the valve ball, water leakage, large impact of the valve ball, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

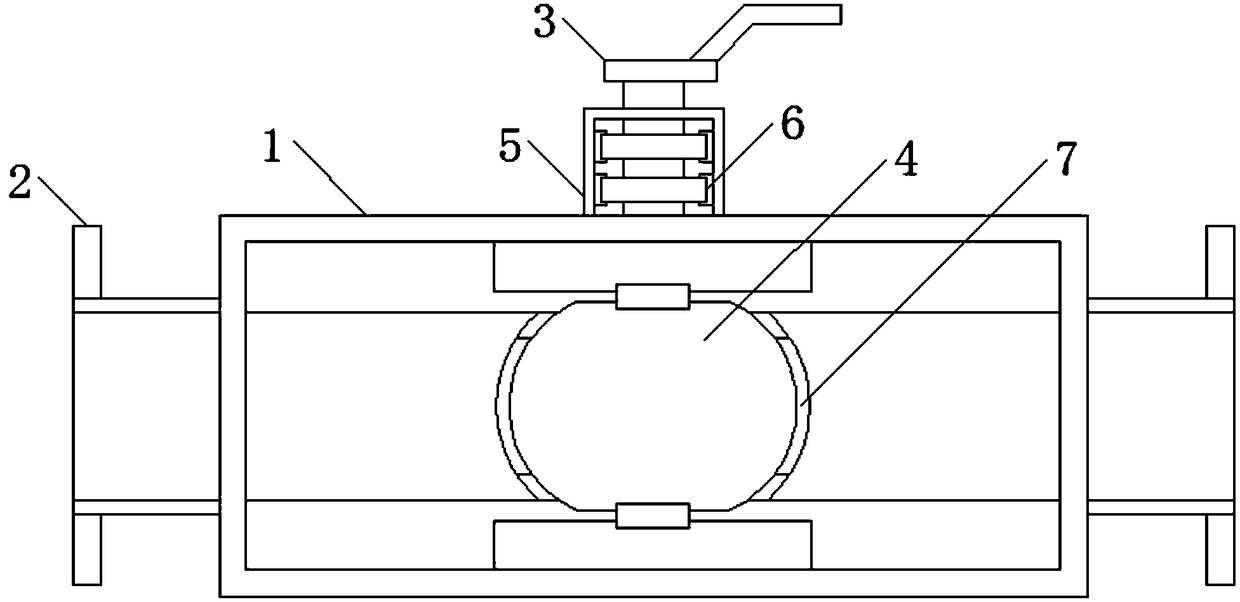

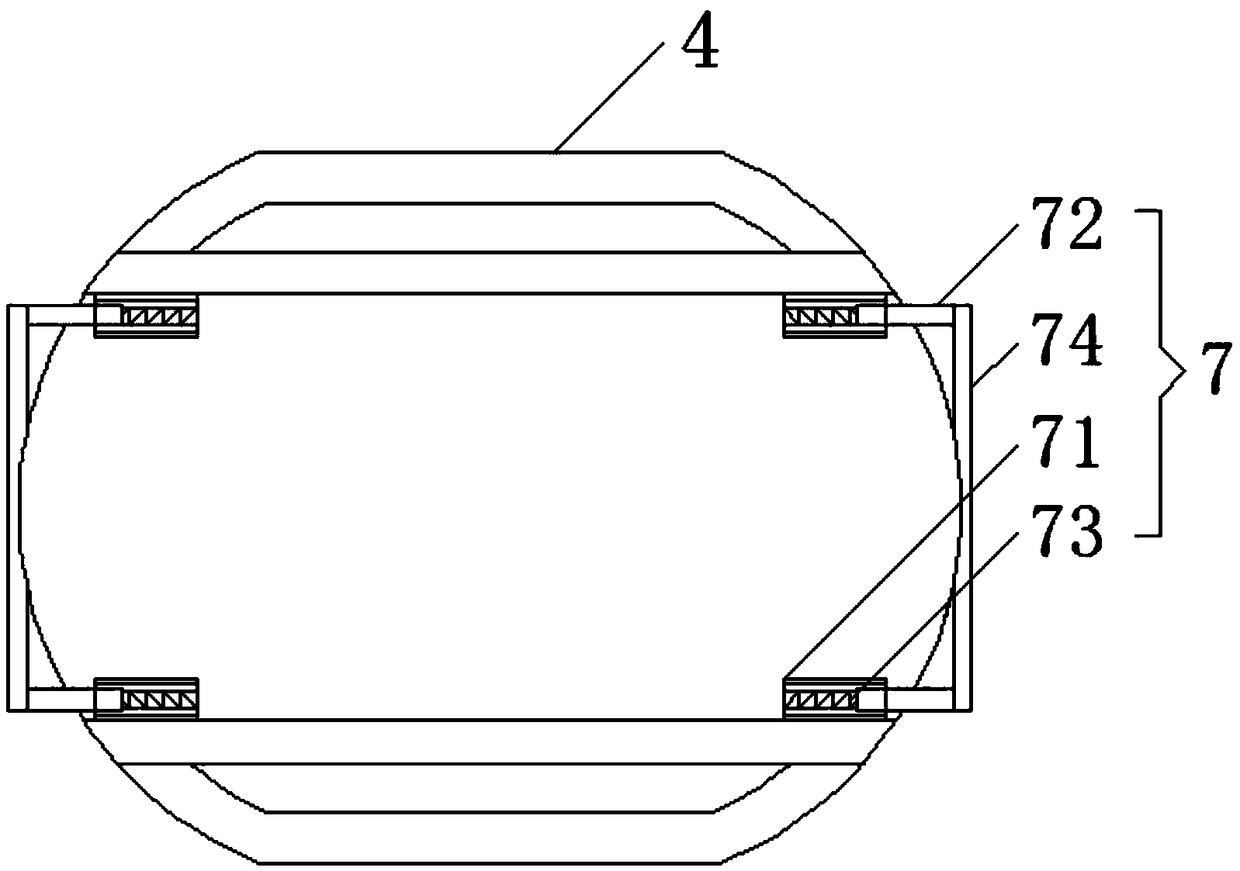

[0021] Embodiment: The valve stem 3 rotates in the limit tube 5 to drive the valve ball 4 to rotate in the valve body 1. When the opening on the valve ball 4 rotates to completely coincide with the water outlet of the water pipe 2, the valve ball 4 The fastening device 7 on the top will be movably plugged into the water pipe 2, and the fastening plate 74 in the fastening device 7 pushes the push rod 72 out of the insert 71 through the telescopic spring 73, thereby pushing the fastening plate 74 to move and clamp On the inner wall of the water pipe 2, so that when the water flow hits the valve ball 4, it will not drive the valve ball 4 to vibrate and shift, which facilitates the circulation of water. When the water pipe 2 is closed, the valve stem 3 drives the valve ball 4 to rotate, and the fastening plate 74 can slide out from the inner wall of water pipe 2 automatically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com