Light filled core bamboo tube structure

A bamboo tube and core-filling technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as low bearing capacity, self-heavy weight, and insufficient section rigidity, so as to improve the bearing capacity under pressure, save material cost, The effect of large section moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will be further described in detail below in conjunction with examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

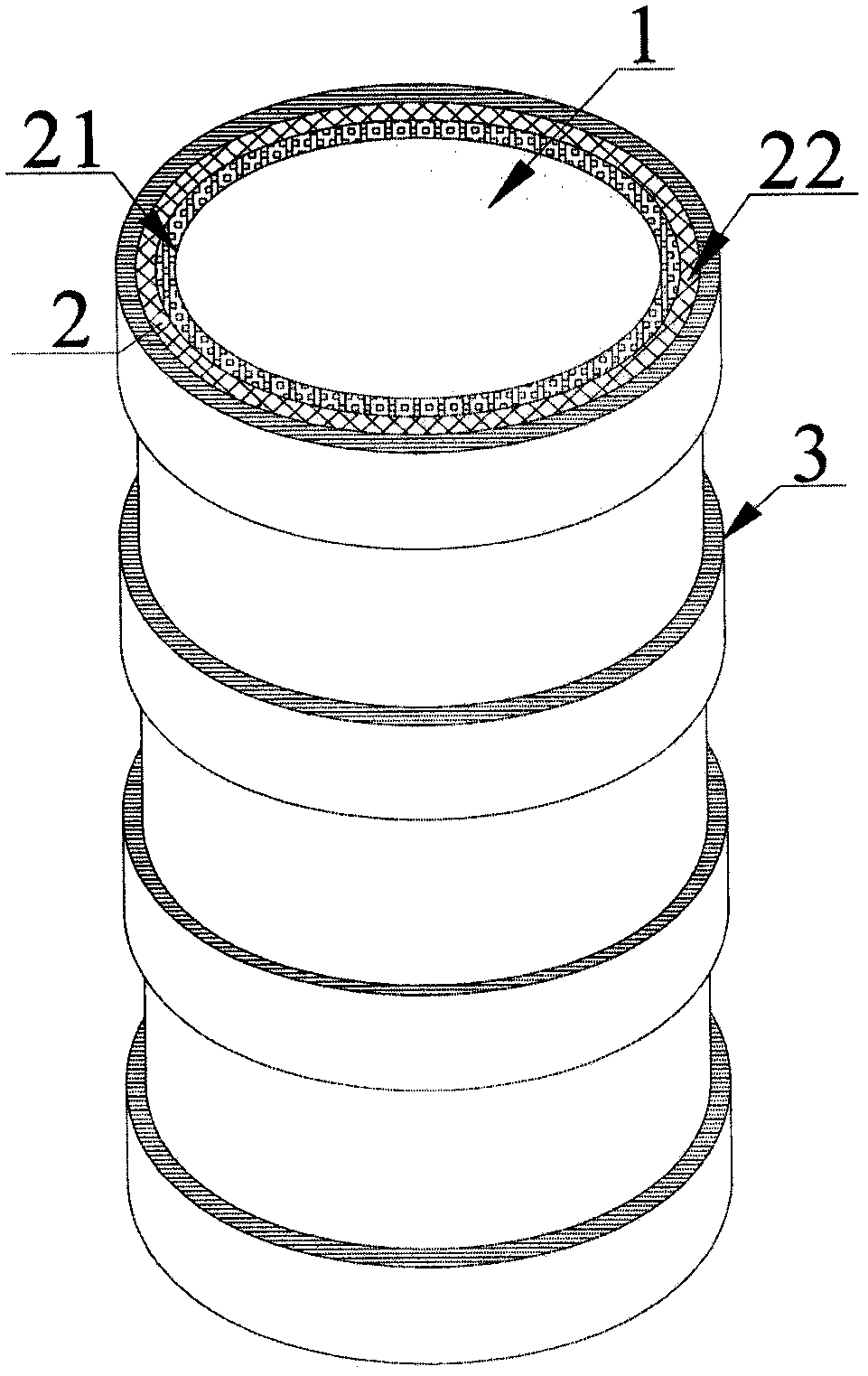

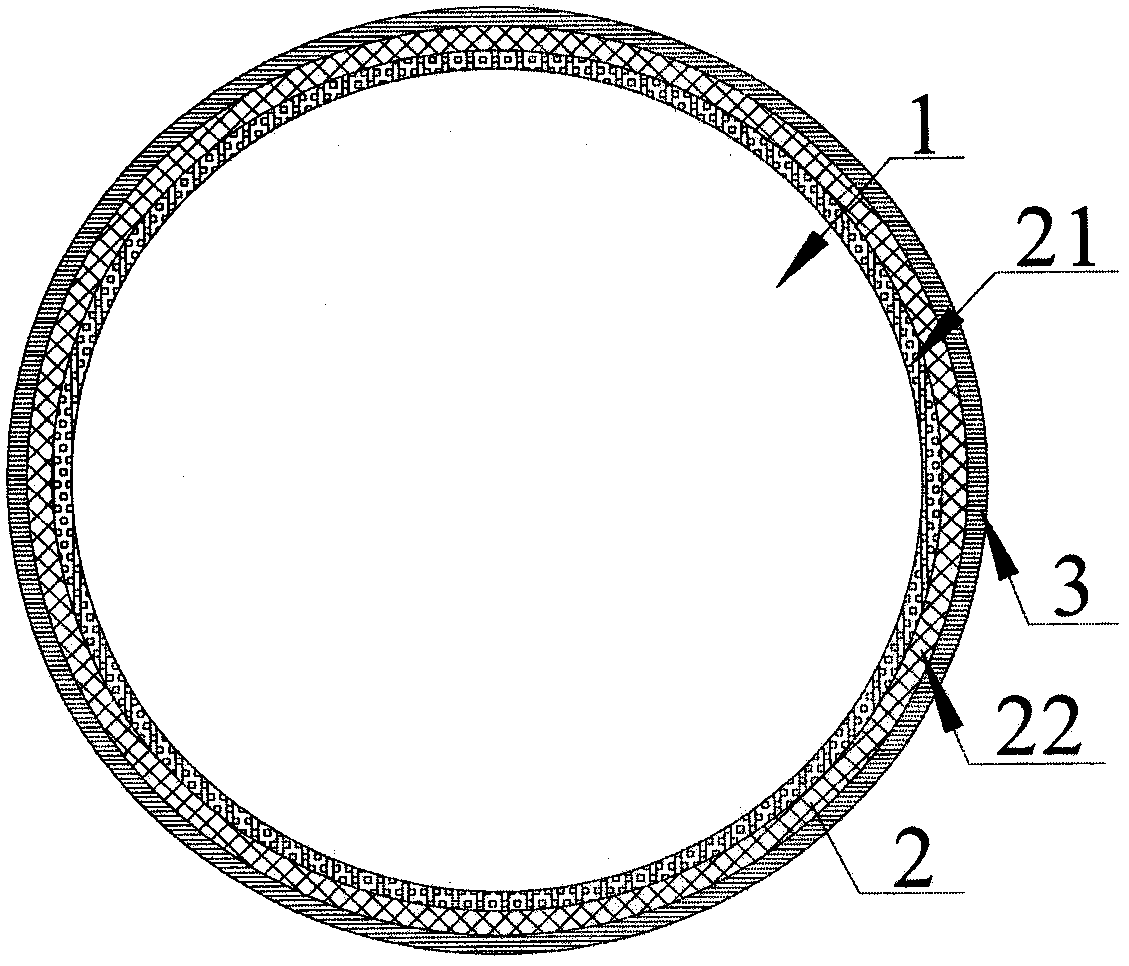

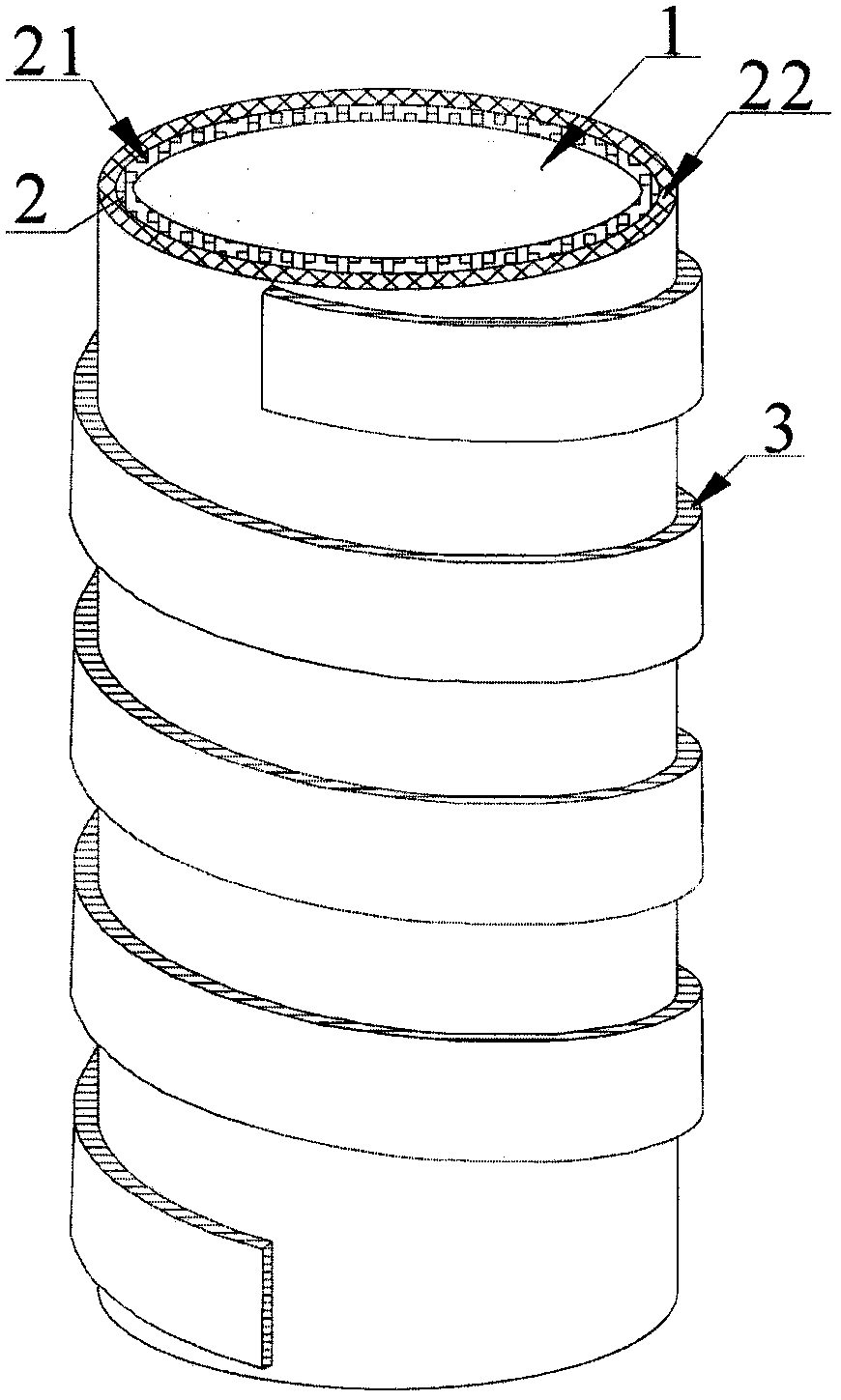

[0026] As shown in the accompanying drawing, a light-weight core-filled bamboo tube structure includes light-weight core-fill 1, bamboo tube 2, and reinforced bamboo belt 3. Light-weight core-fill 1 fills and fills the inner cavity of bamboo tube 2. Light-weight core-fill 1 and the inner wall of the bamboo tube 2 are mutually bonded together, the ratio of the thickness of the side wall of the bamboo tube 2 to the cross-sectional diameter or side length of the entire structure is ≤10%, and the bamboo tube 2 is composed of longitudinal bamboo strips 21 and bamboo coils 22 After being impregnated with adhesive, long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com