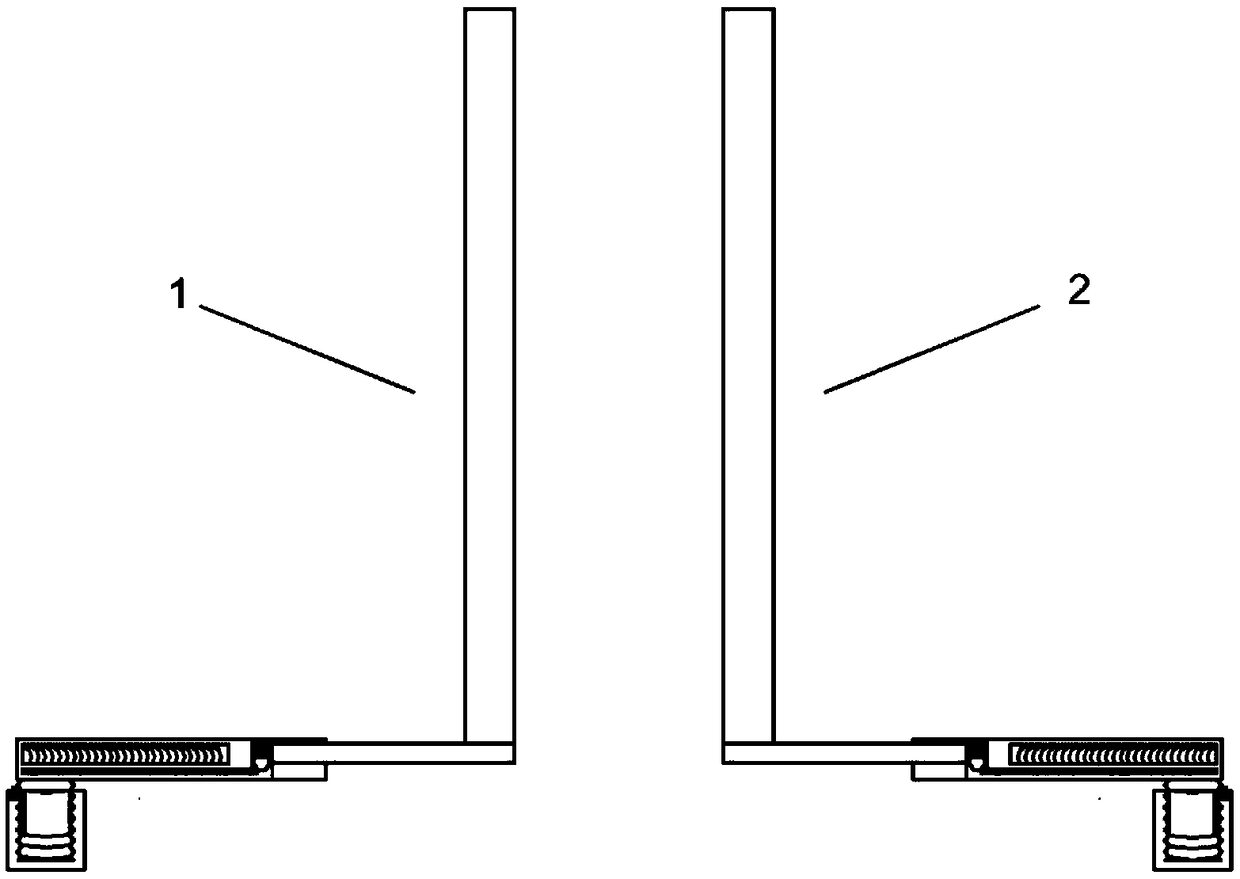

Road column

A technology of road pillars and limit springs, which is applied to roads, roads, road safety devices, etc., can solve problems such as increased road management and maintenance costs, troublesome installation of road pillars, and large road damage, and achieves simple structure, convenient operation, and less The effect of small secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

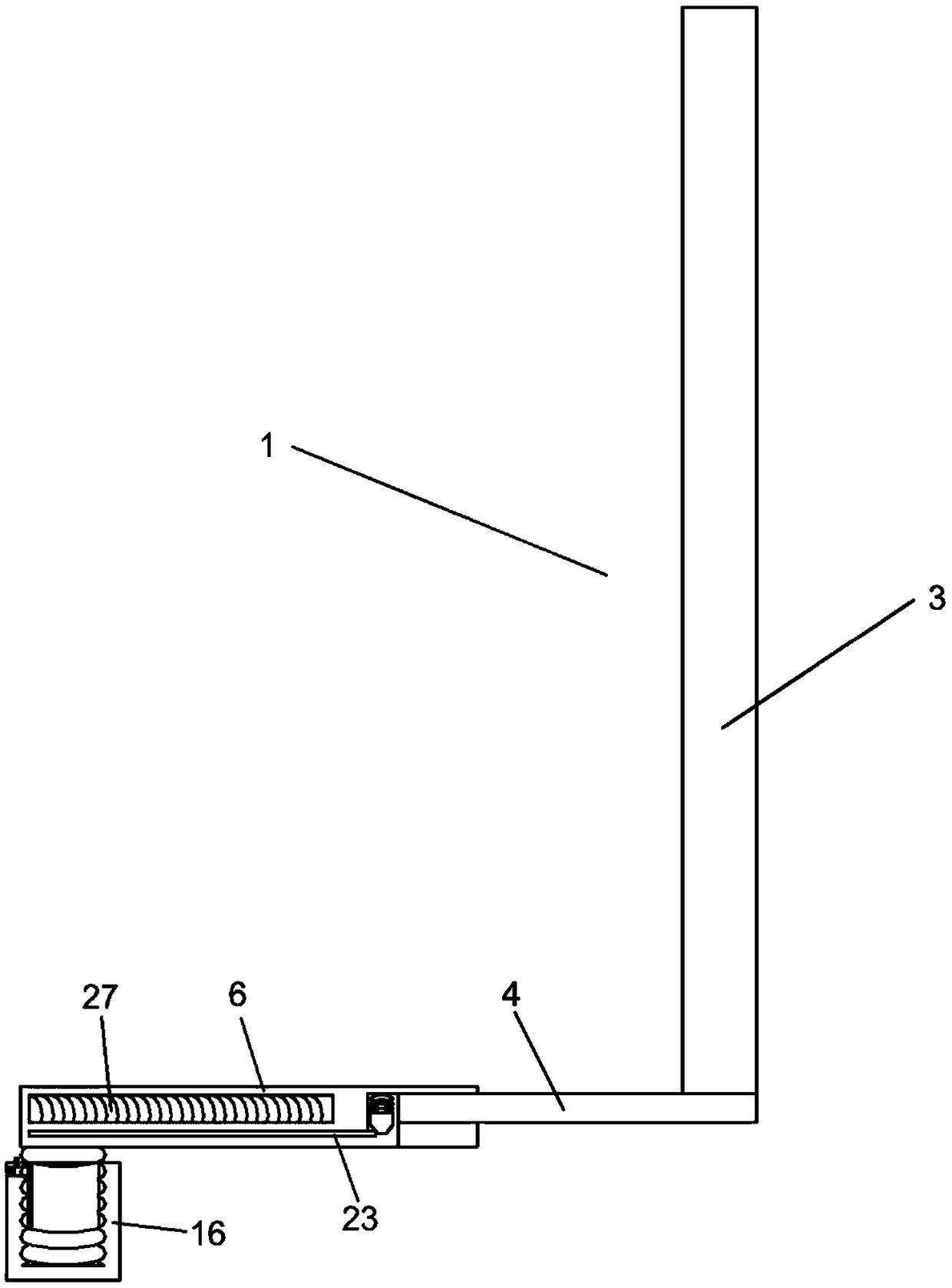

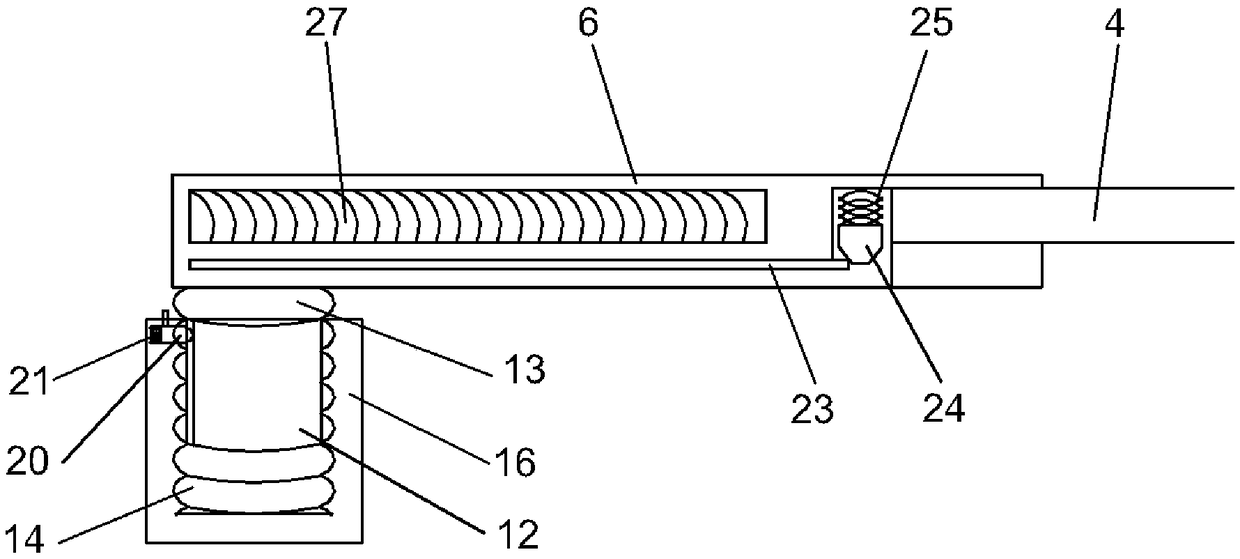

[0050] Specific implementation method: When non-management personnel directly push the width-limiting column 3 by hand, the width-limiting column 3 will swing around the central axis of the base 16; Want to swing around the central axis of the base 16, because the first limit spring 21 of the limit pin 20 is difficult to shrink; the limit pin 20 is stuck in the first square groove 15; the first square groove 15 limits the position of the limit pin 20 swings, so that the fixed width-limiting column 3 will not swing around the central axis of the base 16 under normal circumstances; the manager of the road column adjusts the connecting rod 22 by hand to make the first limit spring 21 contract, and the limit pin 20 releases the pair The restriction of the first square groove 15, so that the position and height of the width-limiting column 3 can be adjusted,

[0051] When non-administrators directly push or pull the width-limiting column 3 with their hands, since the two slopes of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com