Method for dyeing and finishing ultraviolet-proof and rainproof light and thin fabric

An anti-ultraviolet, light and thin technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of color pattern and thin and light fabrics, such as scratching, and achieve good application prospects and excellent anti-ultraviolet effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Fabric → Dyeing (Yuzhongbao KF-333 1g / L, Anocron FXN Scarlet 2.5% o.w.f, Anoke FFO 1g / L, Anoke 509A 0.2g / L, pH 4.5, liquor ratio 1:20, add additives at 60°C and dyes, rise to 90°C at 2°C / min, then rise to 130°C at 1°C / min and keep warm for 30-60min, then drop to 60°C for draining and cleaning)→reduction cleaning (caustic soda 1g / L, hydrosulfite 2g / L, 80°C, cleaning for 20min) → one-step process of functional finishing and shaping (SCJ-966 45g / L, waterproofing agent 403 60g / L, softener 819 25g / L, adhesive KFN-3 30g / L, citric acid 5g / L, 190℃, time 30s.)

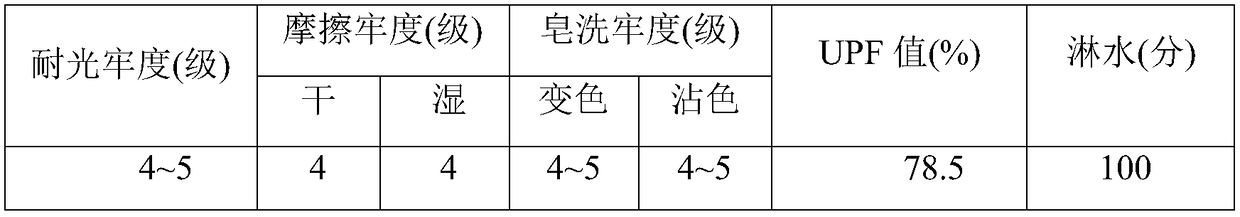

[0040] The properties of the tested fabrics are shown in Table 1.

[0041] Table 1

[0042]

Embodiment 2

[0044] Fabric→Dyeing (Yuzhongbao DM-217 1g / L, Anocron FXN navy blue 3.5%o.w.f, Anoke FFO1.5g / L, Anoke 509A 0.5g / L, pH value 4.5, bath ratio 1:20, add auxiliary dye at 60℃ Agents and dyes, raised to 90°C at 2°C / min, then raised to 130°C at 1°C / min and held for 30-60 minutes, then lowered to 60°C for drain cleaning) → reduction cleaning (caustic soda 2g / L, hydrosulfite 5g / L, 90°C, cleaning for 30min) → one-step process of functional finishing and shaping (SCJ-966 45g / L, waterproofing agent 403 60g / L, softener 819 25g / L, adhesive KFN-3 30g / L, citric acid 5g / L, 180℃, time 35s.)

[0045] The properties of the tested fabrics are shown in Table 2.

[0046] Table 2

[0047]

Embodiment 3

[0049] Fabric → Dyeing (Yuzhongbao CSP-6001 1g / L, AnocronSF Blue 4.5% o.w.f, Anoke FFO 1.5g / L, Anoke 509A 0.5g / L, pH 4.5, liquor ratio 1:20, add additives at 60°C and dyes, raised to 90°C at 2°C / min, then raised to 130°C at 1°C / min and held for 30-60 minutes, then lowered to 60°C for drain cleaning)→reduction cleaning (caustic soda 3g / L, hydrosulfite 5g / L, 80°C, cleaning for 30min) → one-step process of functional finishing and shaping (HTUV100 60g / L, waterproofing agent 403 55g / L, softener 8992 20g / L, adhesive KFN-3 30g / L, citric acid 5g / L , 190°C, time 30s.)

[0050] The properties of the tested fabrics are shown in Table 3.

[0051] table 3

[0052]

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com