Textile cloth dividing device

A technology for textile fabrics and fabric racks, which is applied in the field of textile fabric dividing devices, which can solve problems such as rough edges at the dividing opening, specifications that do not strictly meet the buyer's requirements, and inconvenient use, so as to achieve the effect of neatly dividing the opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

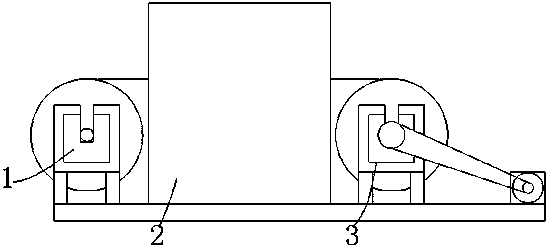

[0022] Such as Figure 1-4 As shown, a textile cloth dividing device includes a textile cloth dividing device, including a cloth releasing device 1, a dividing device 2 and a cloth receiving device 3, the top of the cloth releasing device 1 is fixedly equipped with a dividing device 2, and the top of the cloth releasing device 1 A dividing device 2 is fixedly installed, and a cloth receiving device 3 is fixedly installed on the top of the cloth releasing device 1 .

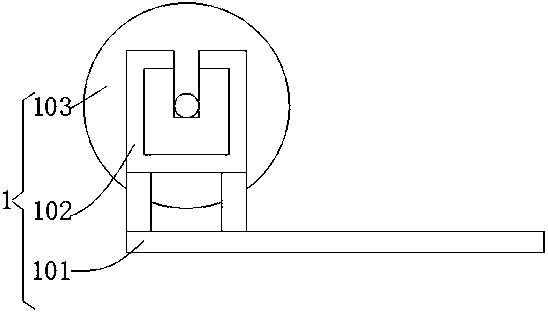

[0023] The cloth releasing device 1 comprises a base 101, a cloth releasing frame 102 is fixedly mounted on the top of the base 101, and a cloth releasing wheel 103 is movably connected to the inside of the cloth releasing frame 102.

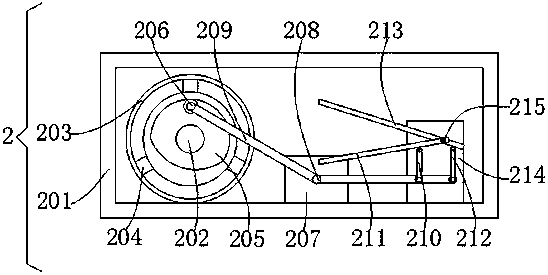

[0024] Separation device 2 comprises casing 201, and the left arm of casing 201 is provided with the strip-shaped through hole that matches with textile cloth, and the right arm of casing 201 is provided with the strip-shaped through hole that matches with textile cloth, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com