Method for separating solvents after chlorination and neutralization reaction of sucralose

A technology of sucralose and separation method, which is applied in chemical instruments and methods, esterified saccharides, sugar derivatives, etc., can solve the problems of low equipment utilization efficiency, complicated operation process, DMF loss, etc., and avoid decomposition and coking. , The method and process are simple, and the effect of clean production is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

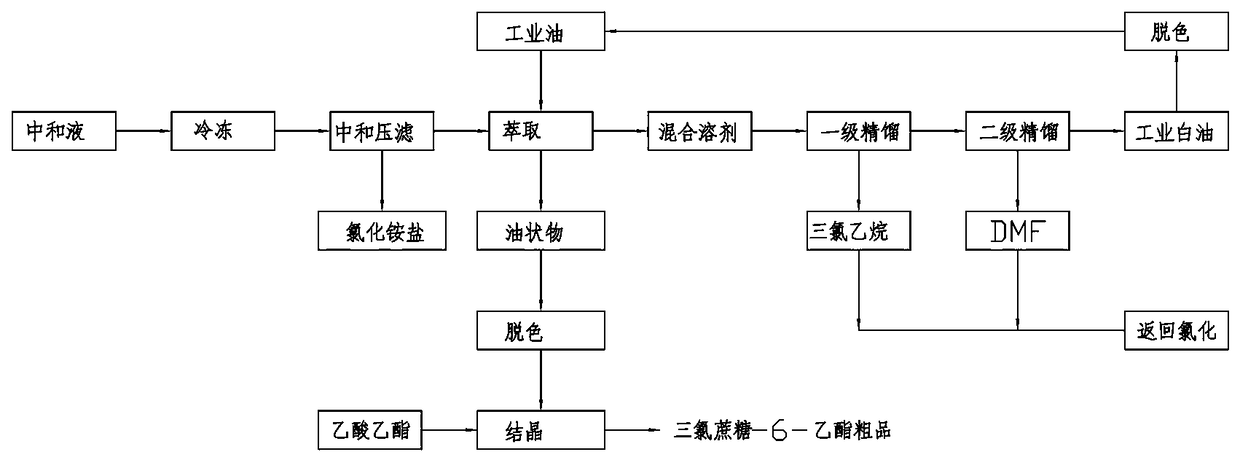

[0019] Such as figure 1 As shown, a method for separating the solvent after the chlorination and neutralization reaction of sucralose provided by the present invention comprises the following steps:

[0020] a. Freeze and cool 8000L neutralizing solution containing sucralose-6-ethyl ester, trichloroethane, DMF, ammonium chloride and some impurities to 0°C, and filter the neutralizing solution through a filter press, and the filtrate enters first Put it in the neutralization liquid tank, then pump it into the extraction kettle, add 3600L10# industrial white oil under the stirring condition, stir for 1 hour and let it stand for stratification;

[0021] b. Put about 500kg of oil in the lower layer extracted and separated into a heat preservation kettle, add 2000L of water, heat to 60°C under normal pressure and cook for 1 hour, add 50kg of activated carbon to decolorize, filter through a filter press to remove activated carbon and some impurities, and the filtrate Enter the crys...

Embodiment 2

[0028] a. Freeze 8000L of neutralizing solution containing sucralose-6-ethyl ester, trichloroethane, DMF, ammonium chloride and some impurities to 5°C, filter the neutralizing solution through a filter press, and the filtrate enters the medium and liquid tank, and then pumped into the extraction kettle, stirring and adding 3400L10# industrial white oil, stirring for 1 hour and then standing for stratification.

[0029] b. Remove the solvent from the upper layer, put about 500kg of oily matter in the lower layer into a heat preservation kettle, add 2000L of water, heat to 60°C under normal pressure, cook for 1 hour, add 50kg of activated carbon for decolorization, and filter through a filter press to remove activated carbon and some impurities , the filtrate enters the crystallization kettle, add 1500L ethyl acetate under stirring and cool down to 5°C, then continue to stir for 3 hours to crystallize the crude product of sucralose-6-ethyl ester, which can be refined to obtain th...

Embodiment 3

[0035] a. Freeze 4000L of neutralizing solution containing sucralose-6-ethyl ester, trichloroethane, DMF, ammonium chloride and some impurities to 5°C, filter the neutralizing solution through a filter press, and the filtrate enters the medium and liquid tank, then pumped into the extraction kettle, stirring and adding 1800L10# industrial white oil, stirring for 1 hour and then standing for stratification.

[0036] b. Remove the solvent from the upper layer, put about 250kg of oil in the lower layer into a heat preservation kettle, add 1000L of water, heat to 60°C under normal pressure and cook for 1 hour, add 25kg of activated carbon for decolorization, and filter through a filter press to remove activated carbon and some impurities , the filtrate enters the crystallization kettle, add 750L of ethyl acetate under stirring and cool down to 0°C, then continue to stir for 3 hours to crystallize the crude product of sucralose-6-ethyl ester, which can be refined to obtain the fine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com