Emergency manual slow-descenting device and lifting equipment thereof

A slow-down and gentle technology, applied in elevators, transportation and packaging, etc., can solve problems such as hidden safety hazards, high speed, wear of friction plates, etc., and achieve the effect of low maintenance cost, low wear resistance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

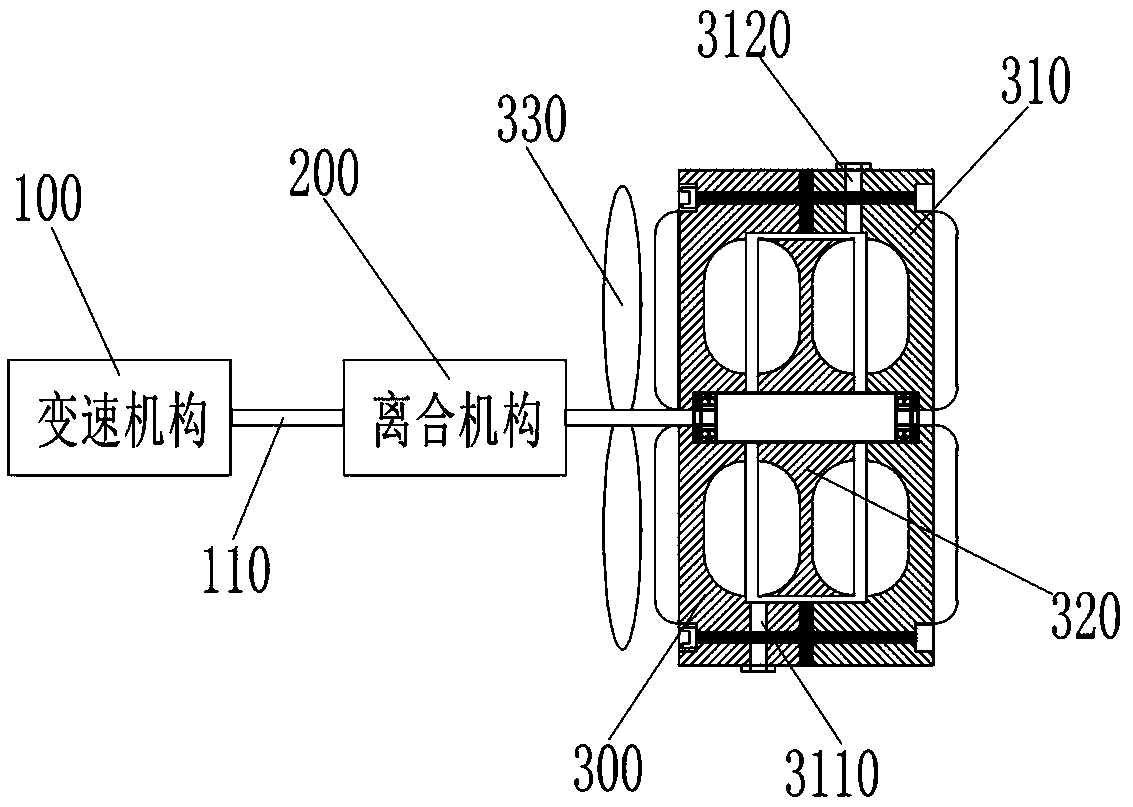

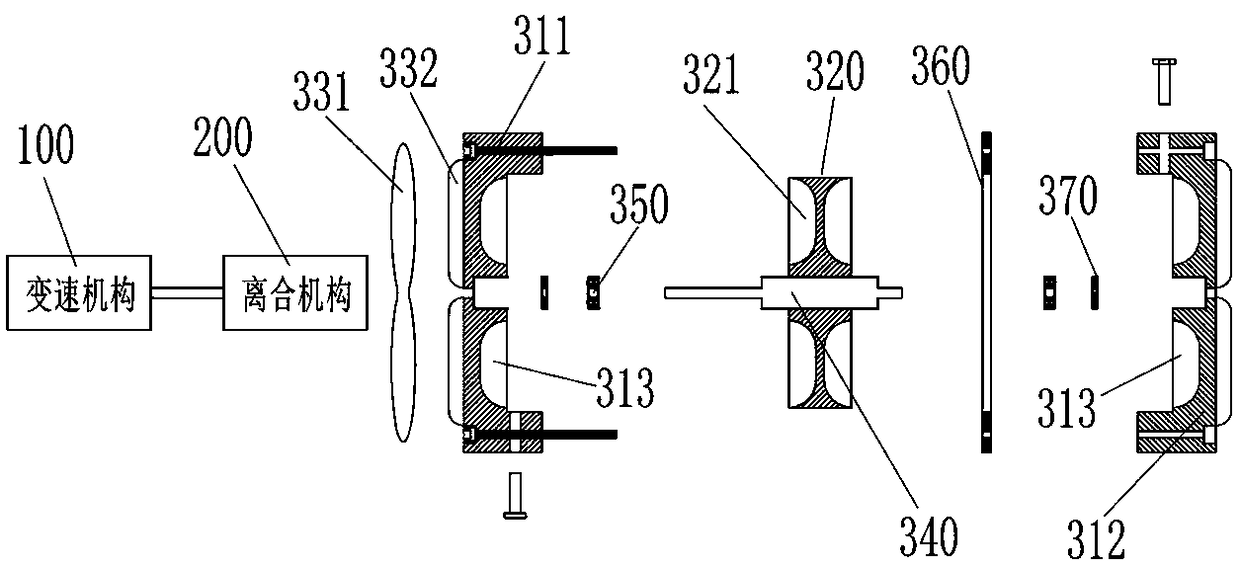

[0036] like figure 1 , figure 2 As shown, an emergency manual slow down device includes a speed change mechanism 100, a clutch mechanism 200 and a slow down mechanism 300. The output end of the speed change mechanism 100 is connected to the clutch mechanism 200 through a high-speed shaft 110. The input end is connected with the clutch mechanism 200 through the input shaft 340 (the clutch mechanism 200 is a mechanical clutch or an electromagnetic clutch, and the effect of the clutch mechanism 200 is to combine and separate the damping effect of the slow-down mechanism 300 and the high-speed shaft of the transmission mechanism 100, The damping effect is not transmitted to the transmission mechanism 100 when the lifting equipment is in normal operation, and the damping effect is transmitted to the transmission mechanism 100 when an emergency manual slow down is required). The slow-down mechanism 300 includes a housing 310, a rotor 320 disposed in the housing 310 and connected t...

Embodiment 2

[0039] like image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the rotor 320 includes a first rotor 3210 and a second rotor 3220, and the first rotor 3210 is connected to the second rotor 3220 through a reversing gear 380. The first rotor 3210 is provided with inclined or vertical first blades 321 , and the second rotor 3220 is provided with inclined or vertical second blades 313 . The first rotor 3210 drives the damping fluid in the sealed cavity to rotate at a high speed through the first blade 321; at the same time, the first rotor 3210 drives the second rotor 3220 to rotate in the opposite direction through the reversing gear 380, and the second blade 313 is relatively opposite to the first rotor 3210. One blade 321 moves in the opposite direction, and transmits the damping effect to the first rotor 3210 through the damping fluid. As the rotating speed increases, the damping effect also increases continuously, and finally reaches a balance.

Embodiment 3

[0041] like Figure 4 As shown, the difference between the third embodiment and the second embodiment is that the speed change mechanism 100 and the clutch mechanism 200 are located on both sides of the slow down mechanism 300 respectively, and the high speed shaft 110 at the output end of the speed change mechanism 100 and the slow down mechanism The input shaft 340 at the input end of 300 is directly connected, and the first rotor 3210 is arranged on the input shaft 340; there is a certain distance between the second rotor 3220 and the first rotor 3210, and the second rotor 3220 is installed axially with the input shaft 340 On the same fixed shaft 390 , the fixed shaft 390 is directly connected with the clutch mechanism 200 . When the damping effect of the slow-down mechanism 300 is needed, the fixed shaft 390 connected to the second rotor 3220 at the non-input end of the slow-down mechanism is locked with the clutch mechanism 200, and the first rotor 3210 drives the airtigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com