Feeding device capable of adjusting discharging amount

A technology of feeding device and material quantity, which is applied in the field of mechanical transportation, can solve the problems that the material discharge quantity cannot be adjusted, cannot be adjusted, and cannot be reached, etc., so as to adjust the material discharge quantity, meet the needs of users, and reduce the whereabouts of materials volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

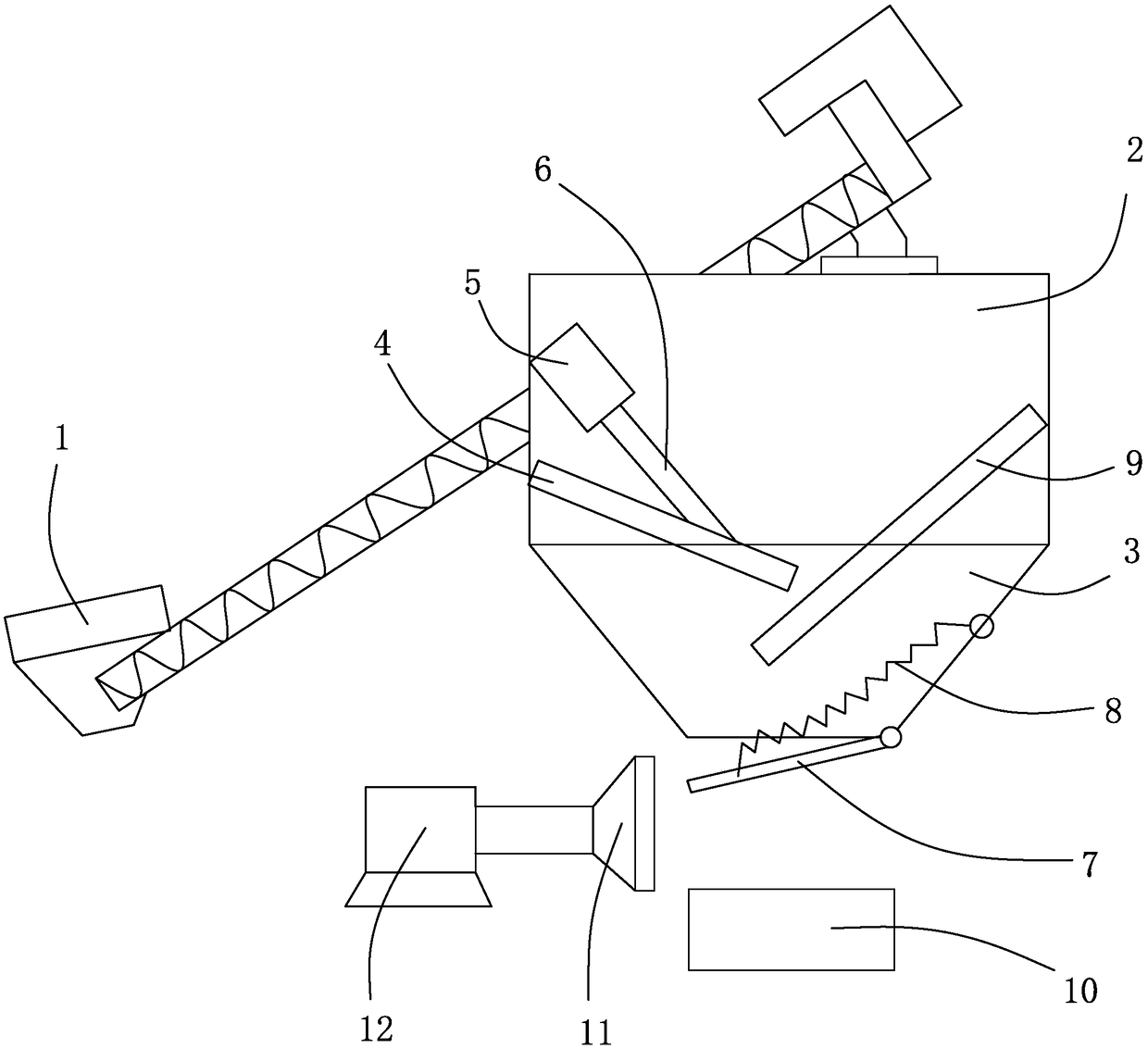

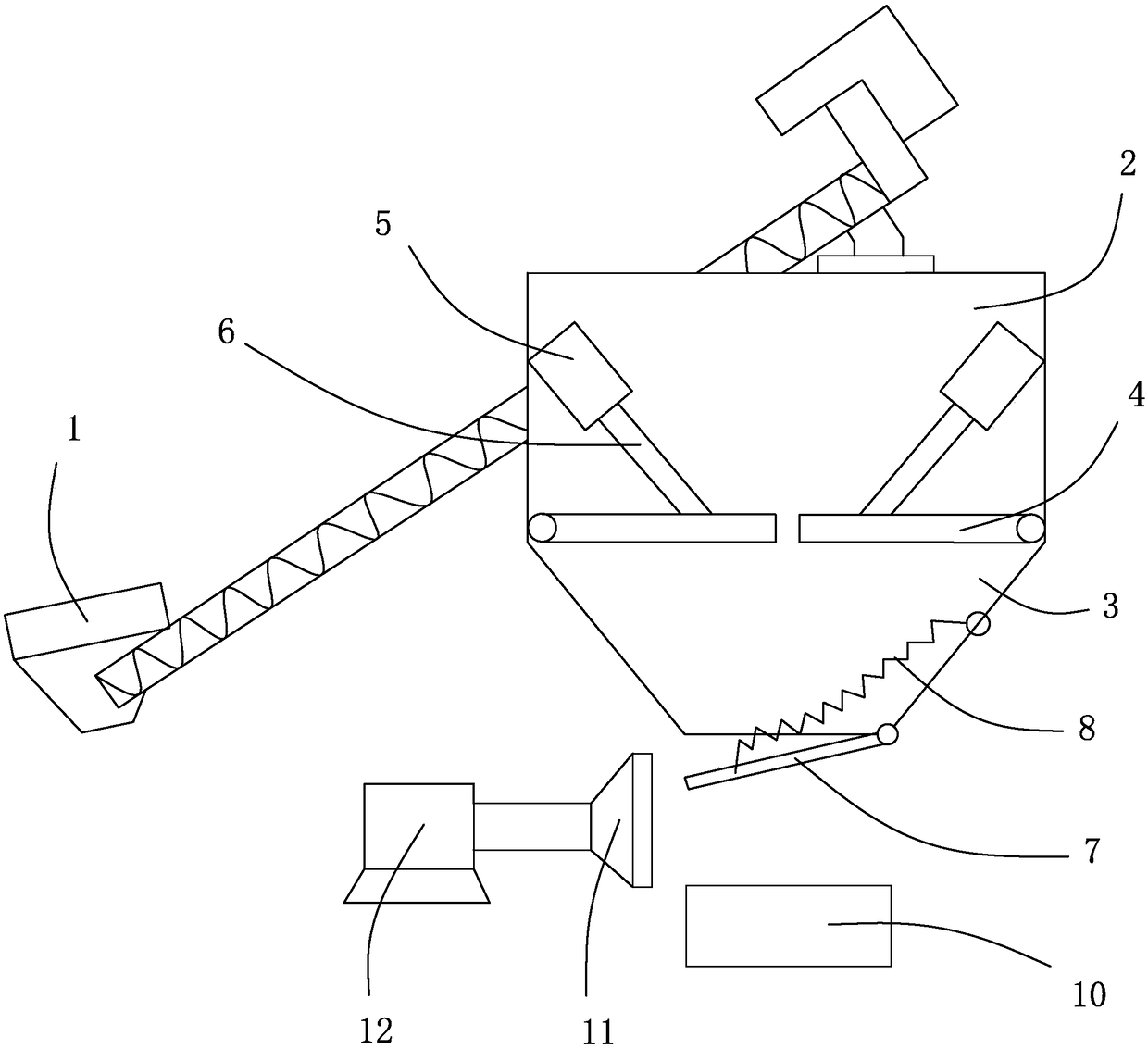

[0018] Such as figure 1 , figure 2 As shown, a kind of feeding device with adjustable feeding amount provided by the present invention includes a hopper 1, a screw conveying mechanism, a silo and a control unit. The material is transported to the upper part of the silo so that the material falls from top to bottom in the silo. The silo includes a cylinder 2 and a conical cylinder 3. The large end of the conical cylinder 3 communicates upward with the cylinder 2, and the conical cylinder 3 The large end is equal to the area of the cross-sectional circle of the cylinder 2, the inner wall of the cylinder 2 is hinged with a movable plate 4, and the inner wall of the cylinder 2 is fixedly connected with the cylinder 5 above the movable plate 4, and the cylinder 5 is electrically connected with the control unit. The telescopic rod 6 is connected to the end of the movable plate 4 away from the hinged position. The telescopic rod 6 of the cylinder 5 moves to control the rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com