Pre-delivery cleaning device for producing plastic shoes

A technology for cleaning equipment and plastics, which is applied to cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc. It can solve the problems of wasting water resources, slow cleaning speed, time-consuming and laborious, and insufficient cleaning of plastic shoes. Achieve the effect of improving cleaning strength, safe and convenient use, and convenient post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

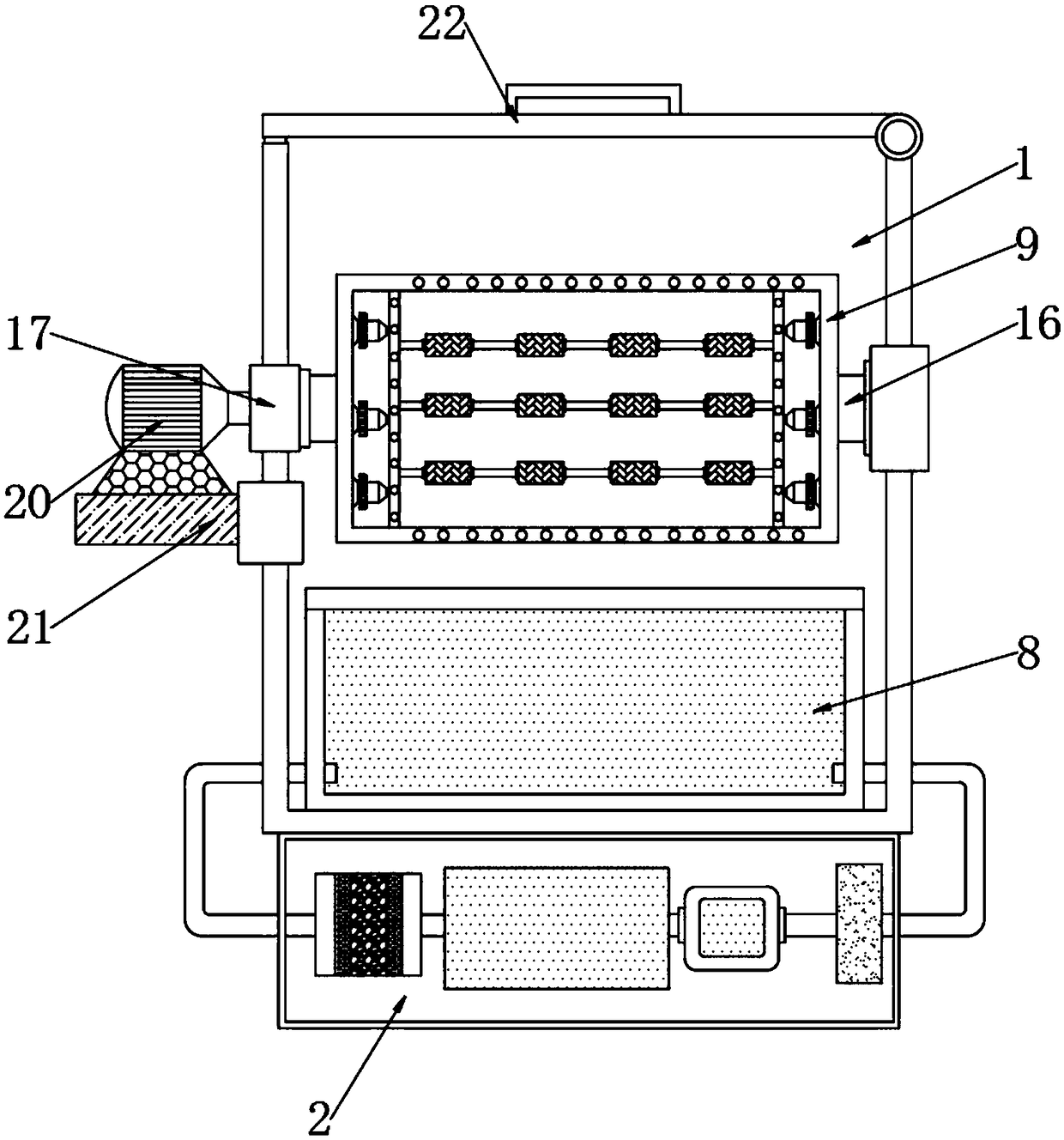

[0023] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a factory cleaning equipment for plastic shoes production, including a cleaning equipment body 1, a water circulation tank 2, a filter plate 3, a water storage tank 4, a water pump 5, a cleaning agent box 6, a circulation connection Water pipe 7, soaking box 8, rotating cleaning basket 9, filter hole 10, cleaning nozzle 11, shielding plate 12, cross bar 13, rotating shaft 14, sponge column 15, connecting rotating shaft 16, slide block 17, buffer plate 18, reducing Shock spring 19, motor 20, support rod 21 and box door 22, cleaning equipment body 1 lower end is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com