Method for building dam through red mud curing and dry heaping and preparing device of mixed slurry for dam building through dry heaping

A technology for red mud and mud, applied in clay preparation devices, cement mixing devices, mixing operation control, etc., can solve the problems of environmental impact around red mud reservoirs, high transportation costs, low dewatering work efficiency, etc., and save dam construction costs. and ash transportation costs, improving strength and compactness, and the effect of high-efficiency gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The dry weight ratio of the three components in the mixed mud of this embodiment is cementitious material: power plant ash: red mud = 0.5:5:10, wherein the excitation components in the cementitious material are industrial by-product gypsum and industrial by-product Produce the mixture of sodium sulfate, its mass percentage is 20%, the mass ratio of industrial by-product gypsum and industrial by-product sodium sulfate in the excitation component is 3:1, and the power plant ash is selected from fly ash, and its mass percentage is 80% .

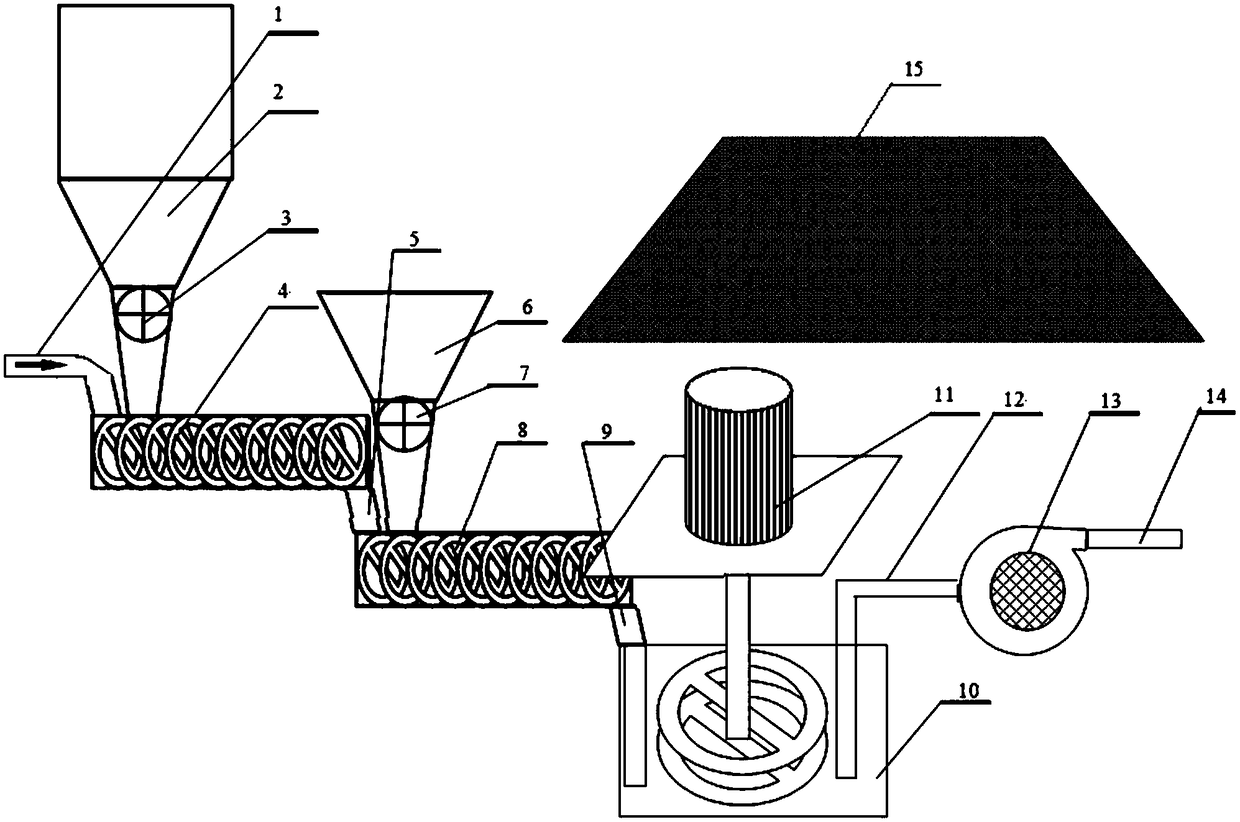

[0040] Such as figure 1 As shown, a mixing workshop for red mud, ash and cementitious materials (preparation device for the above-mentioned mixed mud) is set up near the stockyard. Mud volume, the mixing workshop includes cementitious material silo 2, primary mud mixer 4, ash slag silo 6, secondary mortar mixer 8 and slurry activation storage tank 10, wherein the feed port of primary mud mixer 4 It is connected with the discharge port o...

Embodiment 2

[0049] In this example, the red mud solidification and dry stacking method and the mixed mud preparation device and method are the same as those in Example 1, the difference mainly lies in that the dry weight ratio of the three components in the mixed mud in this example is Concrete material: power plant ash: red mud = 1:3:5, wherein the excitatory component in the cementitious material is a mixture of metakaolin and straw ash, its mass percentage is 30%, and the mass percent of metakaolin and straw ash in the excitatory component The ratio is 2:1, and the power plant ash is CFB sulfur-fixing ash, and its mass percentage is 70%.

Embodiment 3

[0051] In this example, the red mud solidification and dry stacking method and the mixed mud preparation device and method are the same as those in Example 1, the difference mainly lies in that the dry weight ratio of the three components in the mixed mud in this example is Concrete material: power plant ash: red mud = 0.8:4:8, wherein the excitation component in the cementitious material is the mixture of steel slag and carbide slag, its mass percentage is 10%, and the mass ratio of steel slag and carbide slag in the excitation component is 1:4, power plant ash is wet desulfurization ash, its mass percentage is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com