An arm barrel type electronic sphygmomanometer

An electronic sphygmomanometer and arm tube technology, which is applied in the field of sphygmomanometers, can solve problems such as the inability to flexibly adjust the angle and position of the arm tube, and achieve reliable blood pressure values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

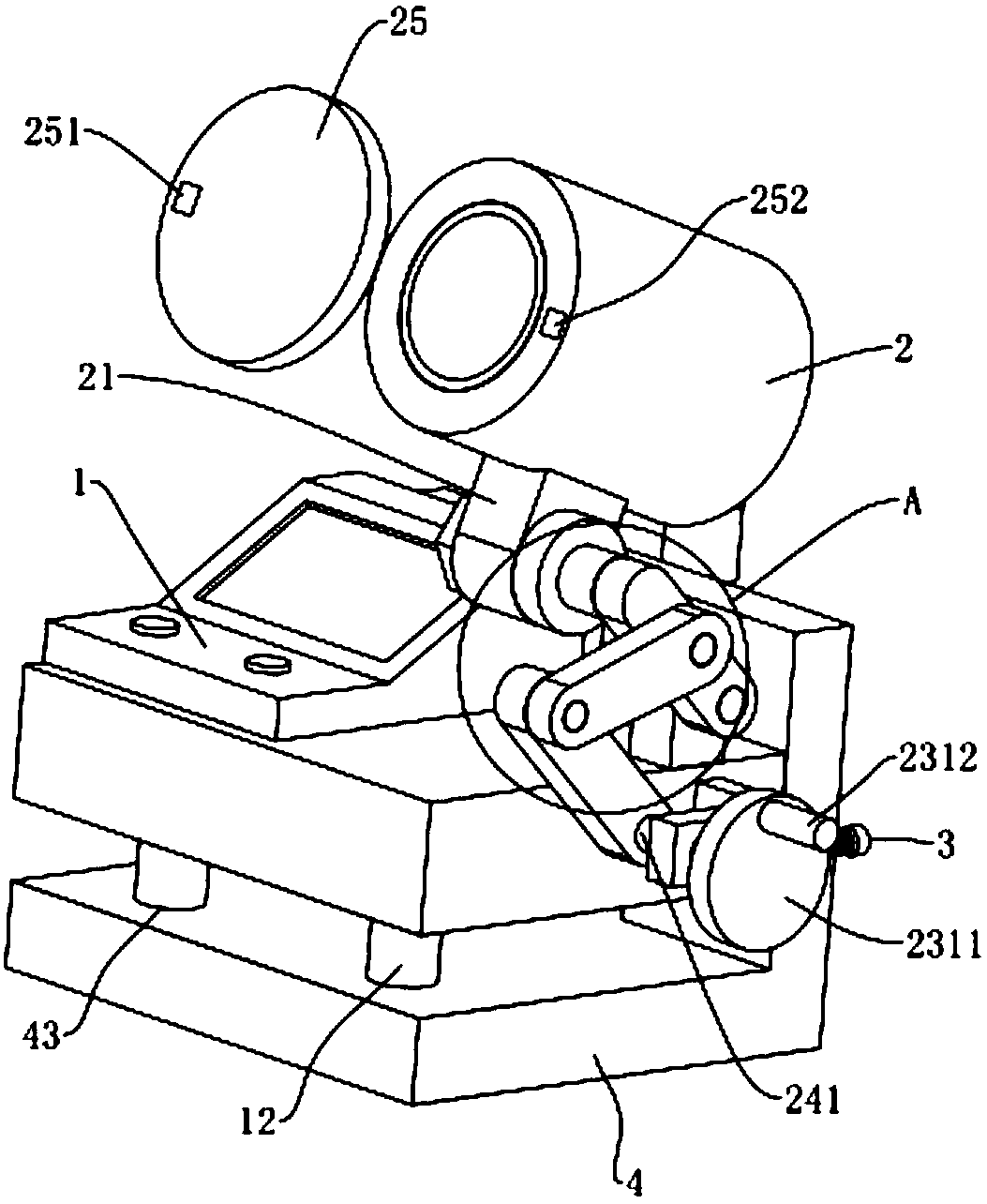

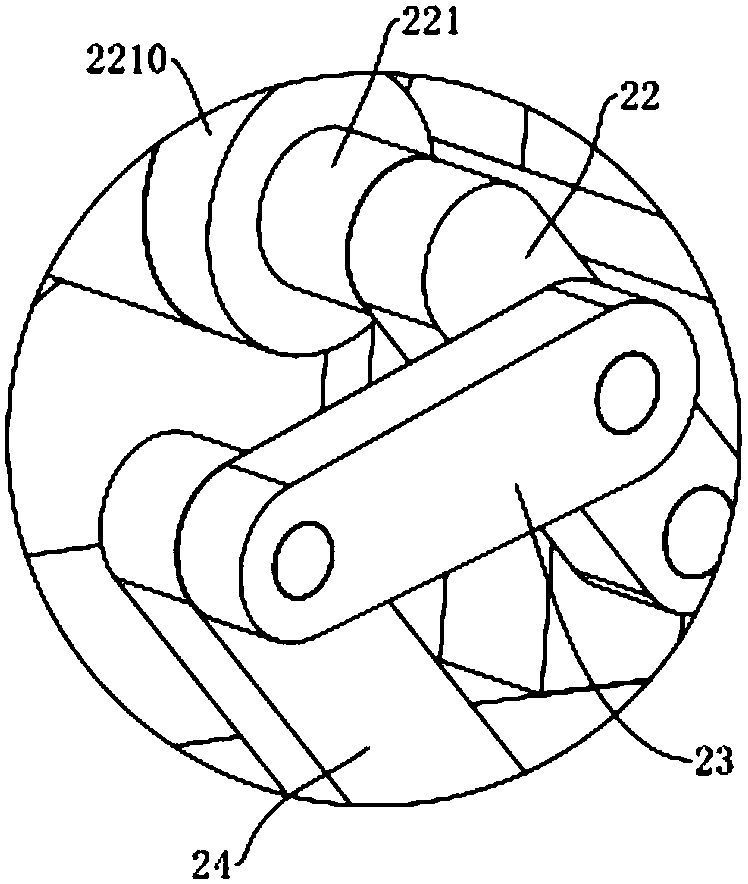

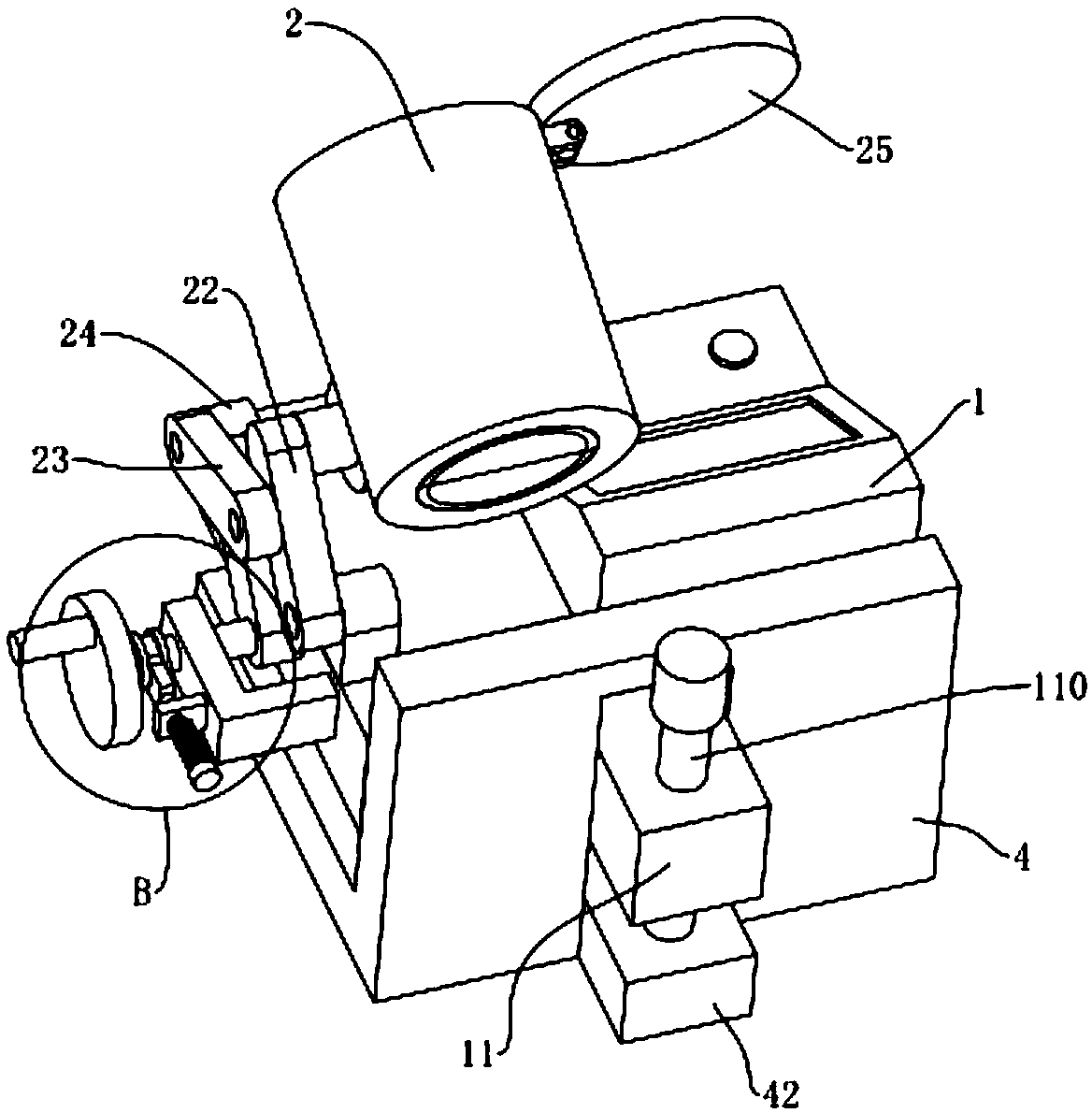

[0044] refer to figure 1 with figure 2 , an arm tube type electronic sphygmomanometer, comprising a body 1, wherein the body 1 is connected with an arm tube 2 for inserting into the arm to detect blood pressure. The blood pressure numbers are reflected on the display on the body 1; due to the integrated design of the arm tube 2 and the body 1 of the traditional electronic blood pressure monitor, the position and angle of the arm tube 2 cannot be adjusted according to the subject to be measured, so the body 1 and the arm tube 1 are now The cylinder 2 is set as a separate type. In order to achieve this purpose, a first connecting rod 21 is fixed at the bottom of the arm cylinder 2. The first connecting rod 21 is detached and connected to the end of the second connecting rod 22, and the second connecting rod 22 is moved away from the One end of the first connecting rod 21 is hinged on the body 1, and a third connecting rod 23 is also hinged at the middle part of the second conn...

Embodiment 2

[0051] The difference from Example 1 is that the surface of the arm barrel 2 is coated with a layer of antifouling coating. Since the arm barrel 2 is a component that is in direct contact with the subject to be tested, the surface of the arm barrel 2 is easy to accumulate dust. In order to prevent The accumulated dust sticks to the surface of the arm barrel 2 and is difficult to clean, so the surface of the arm barrel 2 is coated with an antifouling coating, which makes the arm barrel 2 easy to clean, so a preparation method for the antifouling coating is provided, which has The advantages of short preparation process and simple preparation, wherein the preparation method of the antifouling coating on the surface of the arm barrel 2 is as follows:

[0052] Take the following components by weight for subsequent use: 32 parts of methyl methacrylate, 38 parts of polyethylene, 25 parts of polypropylene, 8 parts of ethyl formate, 8 parts of propylene glycol, 8 parts of polydimethyls...

Embodiment 3

[0058] The difference from Example 2 is the preparation of the antifouling coating on the surface of the arm barrel 2, wherein the preparation method of the antifouling coating is as follows:

[0059] Take the following components by weight for subsequent use: 33 parts of methyl methacrylate, 39 parts of polyethylene, 26 parts of polypropylene, 8 parts of ethyl formate, 8 parts of propylene glycol, 8 parts of polydimethylsiloxane, wood 8 parts of sodium sulfonate;

[0060] S1. Prepare antifouling coating pre-preparation solution: mix methyl methacrylate, polyethylene, polypropylene, and ethyl formate evenly and add to the reaction kettle, heat the temperature in the reaction kettle to 143°C, and then keep it warm for 35 minutes;

[0061] S2. Preparation of antifouling coating solution: After cooling the antifouling coating pre-preparation solution obtained in S1 to 93°C, add propylene glycol, polydimethylsiloxane, and sodium lignosulfonate to the reaction kettle, and then The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com