Spatial full-angle ultrasonic optical fiber Fabry-Perot sensor for monitoring partial discharge of liquid-solid composite insulated power equipment

A technology of composite insulation and power equipment, applied in the field of ultrasonic optical fiber method-Perkin sensor, which can solve the problem that the extrinsic optical fiber method-Perkin sensor cannot detect ultrasonic signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

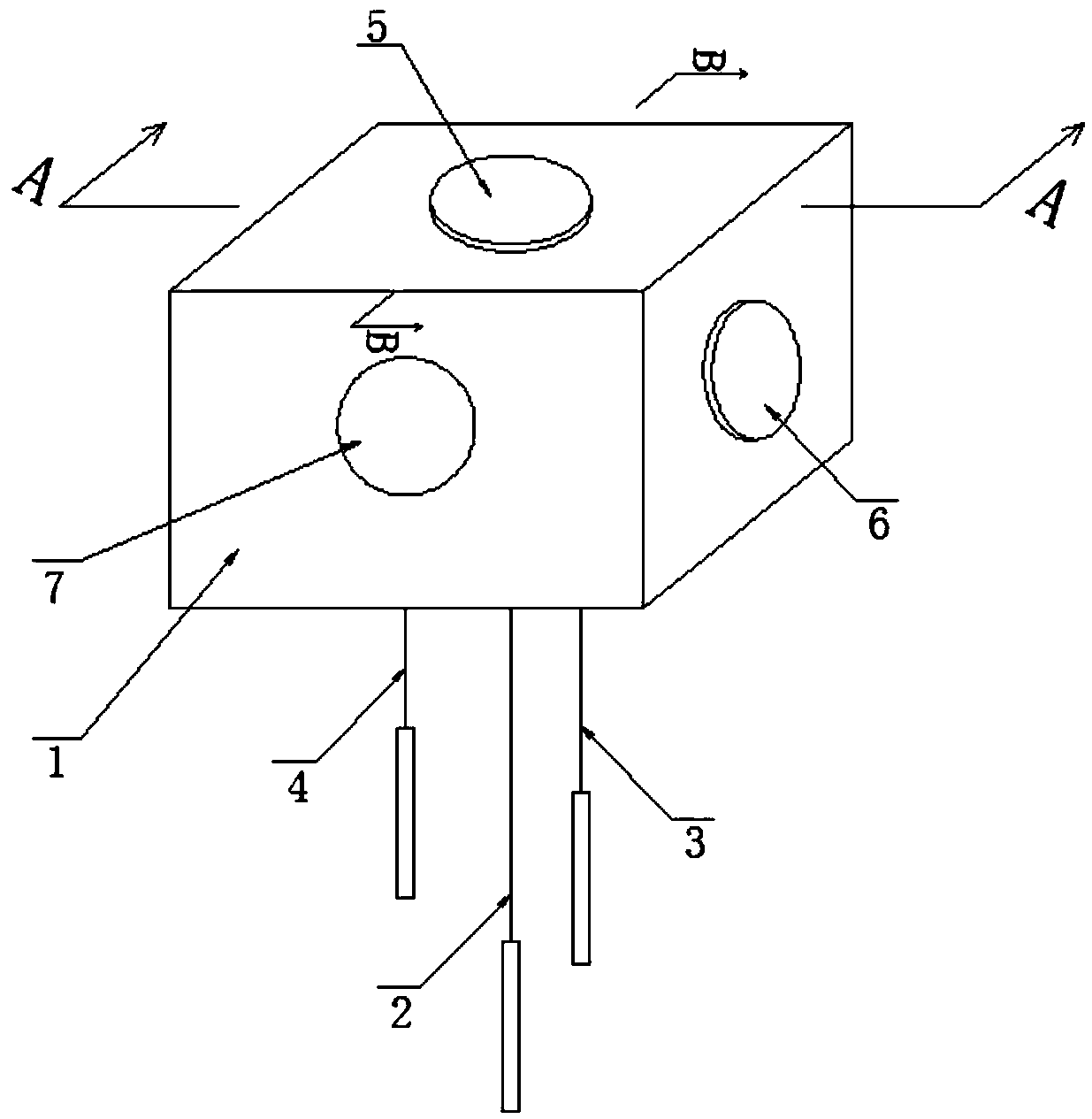

[0030] Specific implementation mode one: combine Figure 1~4 This embodiment is described. This embodiment is used to monitor the partial discharge of liquid-solid composite insulated power equipment. The spatial full-angle ultrasonic optical fiber method-Pur sensor consists of a basic support body 1, a planar optical fiber pigtail 2, a first 45-degree inclination angle pigtail 3, and a second optical fiber pigtail. Two 45-degree inclined pigtails 4, the first sensing diaphragm 6, the second sensing diaphragm 7 and the third sensing diaphragm 5 are formed;

[0031] The basic support body 1 is in the shape of a cuboid, and a vertical inline-shaped through hole is arranged in the basic support body 1. The upper end of the inline-shaped through hole is a circular counterbore with a trapezoidal cross section, and the outer end surface of the counterbore is covered with a third sensing sensor. Diaphragm 5; the first L-shaped through hole is composed of a vertical blind hole and a h...

specific Embodiment approach 2

[0039] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the first sensing diaphragm (6), the second sensing diaphragm (7) and the third sensing diaphragm (5) are circular The sheet-shaped quartz glass, the surface of the circular sheet-shaped quartz glass facing the basic support body (1) is coated with an all-dielectric reflection film. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0040] Embodiment 3: This embodiment is different from Embodiment 2 in that: the reflectivity of the all-dielectric reflection film is 50%. Other steps and parameters are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com