Method for differentiating oolong tea with different producing areas and fermentation types

An oolong tea, type technology, applied in the direction of material separation, analysis materials, measuring devices, etc., to achieve accurate evaluation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

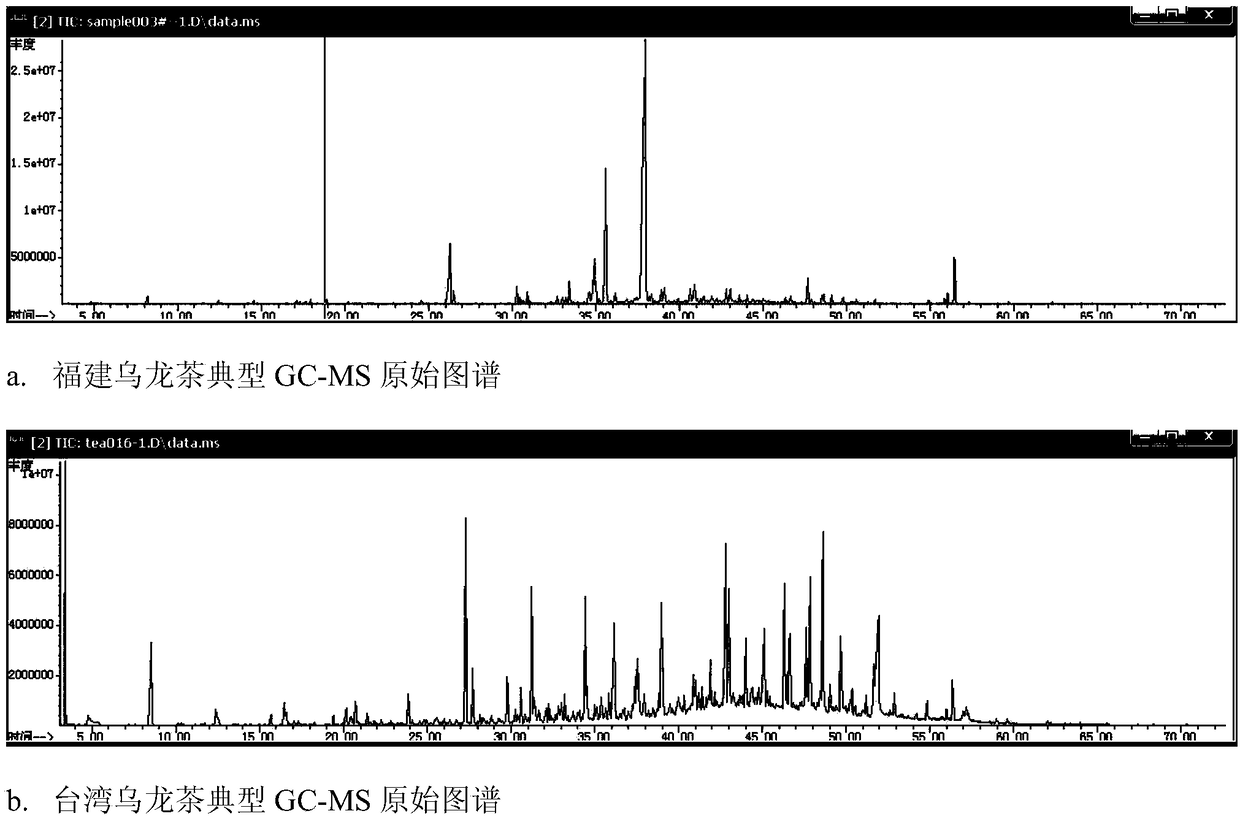

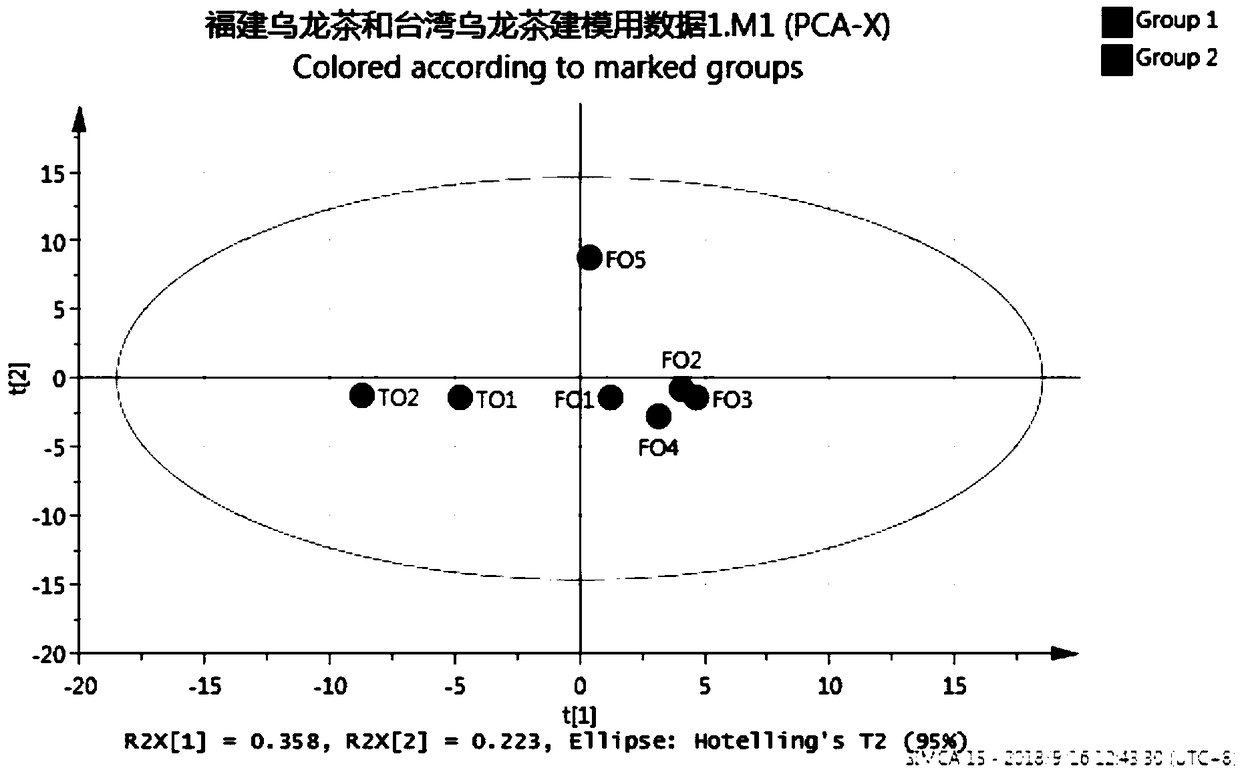

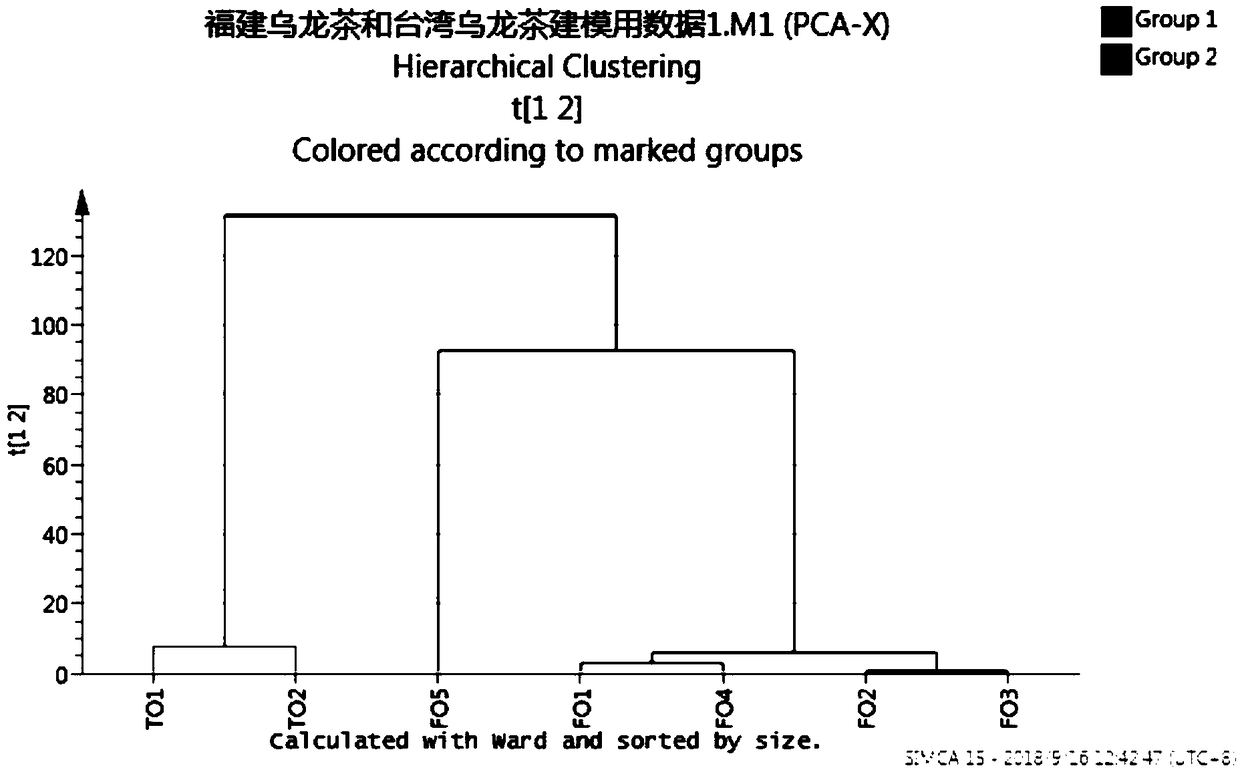

[0044] Embodiment 1: A kind of method utilizing full-automatic headspace solid-phase microextraction in conjunction with gas chromatography mass spectrometry and chemometric method to distinguish different production areas of oolong tea, concrete steps are as follows:

[0045] (1) Material preparation: 5 oolong tea samples are from Fujian Province, numbered FO1-FO5, 2 oolong tea samples are from Taiwan, numbered TO1-TO2, and the production year of all teas is 2013.

[0046] (2) Sample preparation: The PDMS / DVB / CAR extraction fiber head was aged at 250°C for 60 min at the GC inlet. Accurately weigh 2g of tea powder for each tea sample, put it into a 20mL headspace bottle, add 5mL of boiling distilled water for brewing, immediately seal the bottle mouth, and brew for 2 minutes. Then place it in the incubator of the headspace sampler at a speed of 250r / min. After equilibrating at 80°C for 10min, the autosampler inserts the extraction head into the headspace part of the headspace ...

Embodiment 2

[0049] Embodiment 2: a kind of method utilizing automatic headspace solid-phase microextraction in conjunction with gas chromatography mass spectrometry and chemometrics method to distinguish different fermented types of oolong tea, concrete steps are as follows:

[0050] (1) Material preparation: 5 lightly fermented oolong tea samples were from Fujian Province, numbered QO1-QO5. 3 heavily fermented oolong tea samples were from Fujian, Guangdong and Taiwan, numbered ZO1-ZO3, and the production years were year 2013.

[0051] (2) Sample preparation: The PDMS / DVB / CAR extraction fiber head was aged at 250°C for 60 min at the GC inlet. Accurately weigh 2g of tea powder for each tea sample, put it into a 20mL headspace bottle, add 5mL of boiling distilled water for brewing, immediately seal the bottle mouth, and brew for 2 minutes. Then place it in the incubator of the headspace sampler at a speed of 250r / min. After equilibrating at 80°C for 10min, the autosampler inserts the extra...

Embodiment 3

[0054] Embodiment 3: a kind of method utilizing full-automatic headspace solid-phase microextraction in combination with gas chromatography mass spectrometry and chemometrics method to distinguish the Tieguanyin produced in Fujian and other oolong teas produced in Fujian, the specific steps are as follows:

[0055] (1) Material preparation: 4 Tieguanyin samples are from Fujian Province, numbered FT1-FT4. The other two oolong tea samples also come from Fujian, namely Huang Jin Gui and Da Hong Pao, numbered FO1-FO2, both produced in 2013.

[0056] (2) Sample preparation: The PDMS / DVB / CAR extraction fiber head was aged at 250°C for 60 min at the GC inlet. Accurately weigh 2g of tea powder for each tea sample, put it into a 20mL headspace bottle, add 5mL of boiling distilled water for brewing, immediately seal the bottle mouth, and brew for 2 minutes. Then place it in the incubator of the headspace sampler at a speed of 250r / min. After equilibrating at 80°C for 10min, the autosam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com