Fire clay for firework inner cylinder

An inner tube, used technology, applied in the direction of fireworks, offensive equipment, weapon types, etc., can solve the problems of affecting the discharge effect, the thickness of the fire mud cannot be freely stretched, and the process is complicated, so as to eliminate the problem of no fire and ensure the overall quality. and firing effect, the effect of simplifying the production process

Inactive Publication Date: 2019-01-08

浏阳市金利出口烟花制造有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the prior art, the firework inner tube part is filled with fire clay in the paper tube, and then the fire clay is inserted through the fire, and the firework inner tube is ignited by fire. Due to the complicated process, the quality of the lead wire cannot be guaranteed, and there is no connection. The probability of fire affects the discharge effect, and the thickness of overfire mud is limited and cannot be freely expanded

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

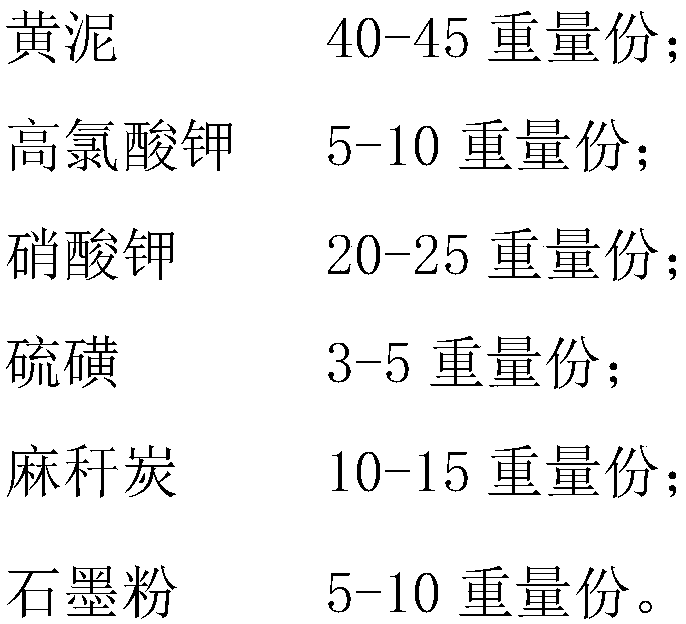

[0013] The proportioning of parts by weight of each component is:

[0014]

Embodiment 2

[0016] The difference between this embodiment and embodiment 1 is that the proportioning of parts by weight of each component is:

[0017]

[0018]

Embodiment 3

[0020] The difference between this embodiment and embodiment 2 is that the proportioning of parts by weight of each component is:

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses fire clay for a firework inner cylinder. The fire clay is characterized by comprising yellow mud, potassium hyperchlorate, nitrate of potash, sulphur, hemp stalk charcoal and graphite powder, and comprising, by weight, 40-45 parts of the yellow mud, 5-10 parts of the potassium hyperchlorate, 20-25 parts of the nitrate of potash, 3-5 parts of the sulphur, 10-15 parts of thehemp stalk charcoal and 5-10 parts of the graphite powder. The components are simple, and preparation is easy. When the fire clay is positioned into a firework inner cylinder, fire inducing is not required. The manufacturing procedure of the firework inner cylinder is simplified, the displaying effect of the firework inner cylinder is guaranteed, higher safety and reliability are achieved.

Description

technical field [0001] The invention relates to the technical field of fireworks products, in particular to fired clay for inner tubes of fireworks. Background technique [0002] In the prior art, the firework inner tube part is filled with fire clay in the paper tube, and then the fire clay is inserted through the fire, and the firework inner tube is ignited by fire. Due to the complicated process, the quality of the lead wire cannot be guaranteed, and there is no connection. The probability of fire affects the discharge effect, and the thickness of the overfire mud is limited and cannot be freely expanded. Contents of the invention [0003] Aiming at the problems of the prior art, the present invention proposes an overfired clay for the inner cylinder of fireworks, which has simple components and is easy to prepare. After being used in the inner cylinder of fireworks, there is no need for overheating, which simplifies the production process of the inner cylinder of firew...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F42B4/30

CPCF42B4/30

Inventor 朱雪丰

Owner 浏阳市金利出口烟花制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com