Chemical production equipment and working method thereof

A technology for chemical production and working methods, applied in the chemical industry, which can solve the problems of occupation, time difference, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

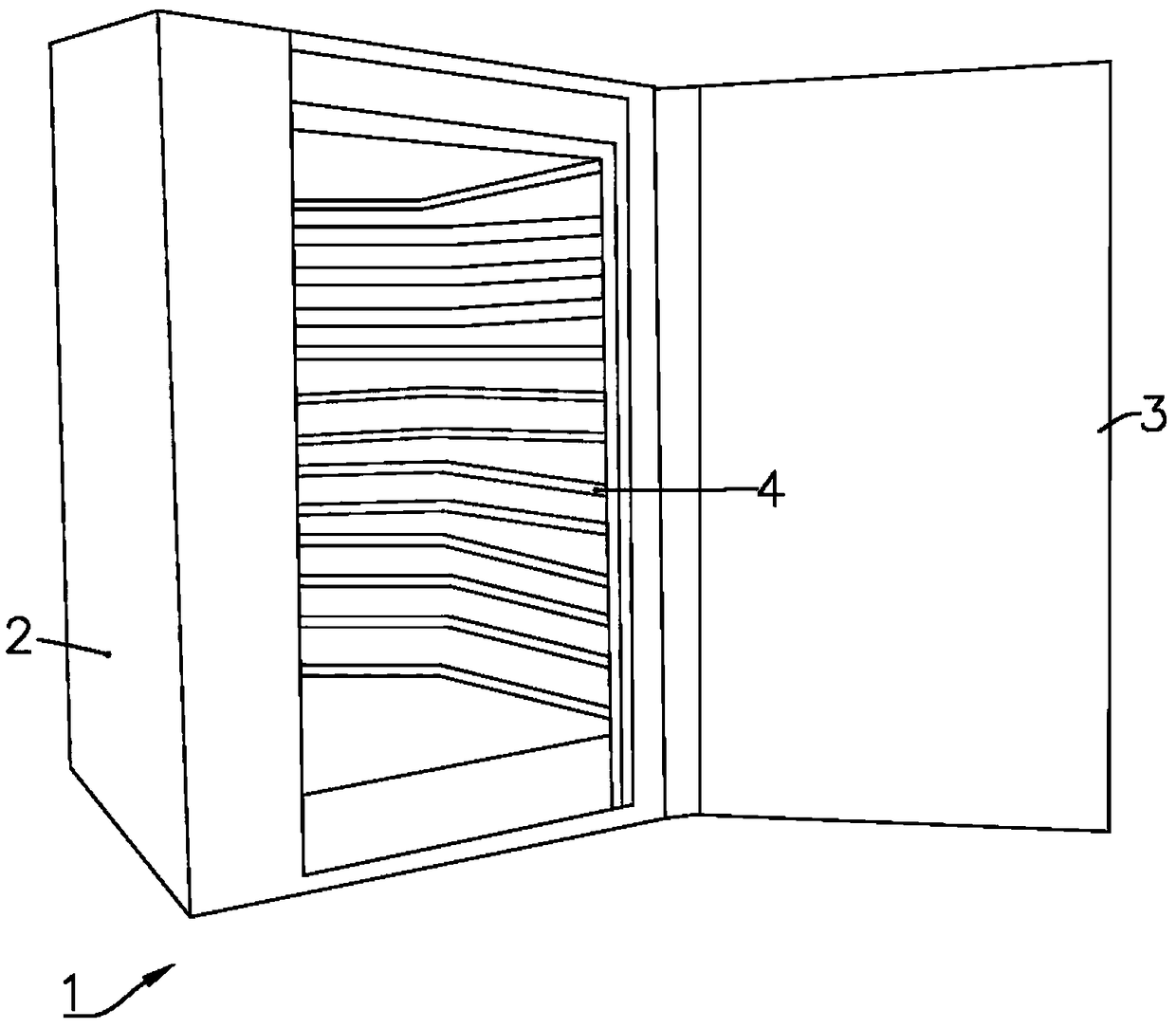

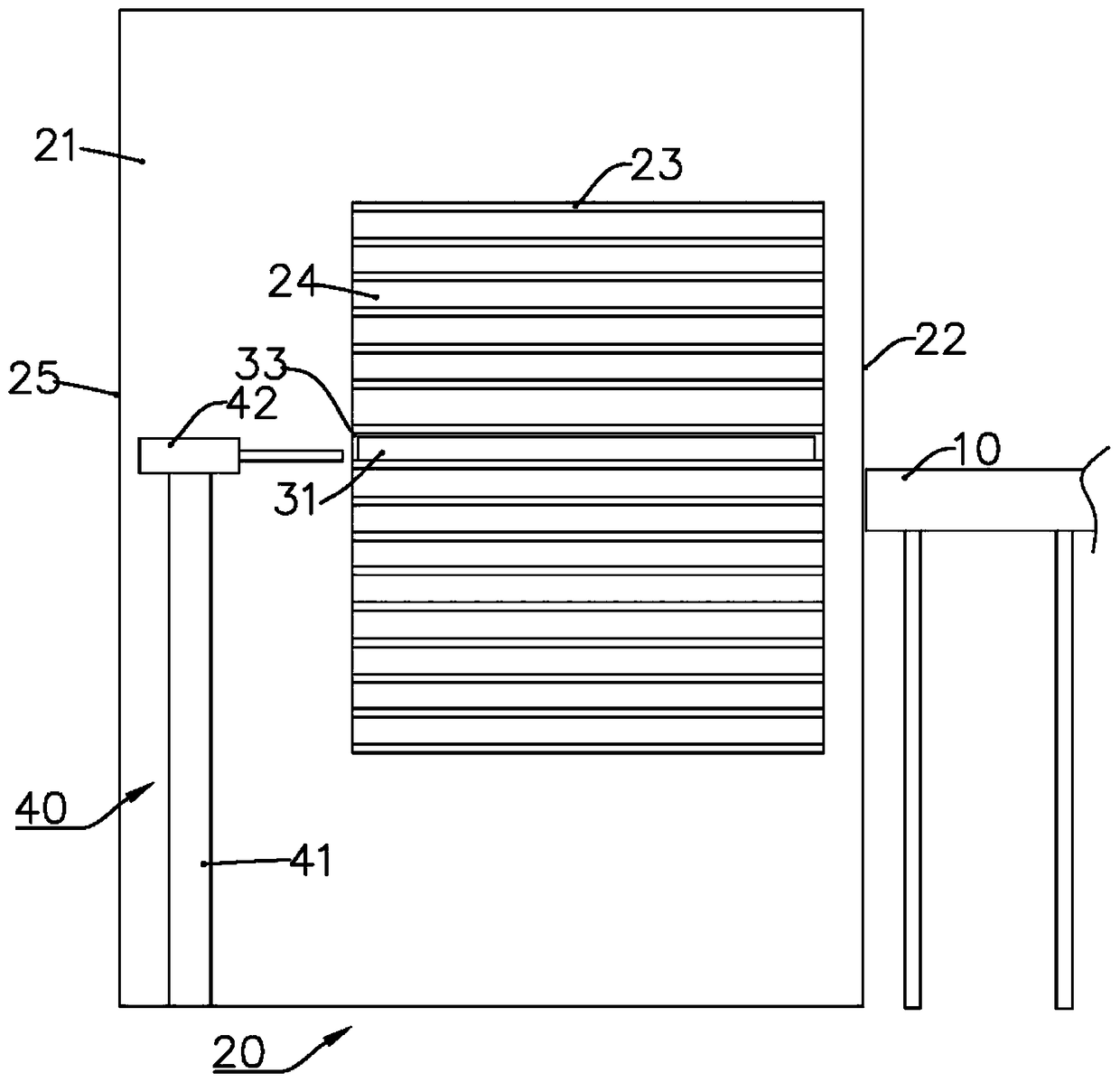

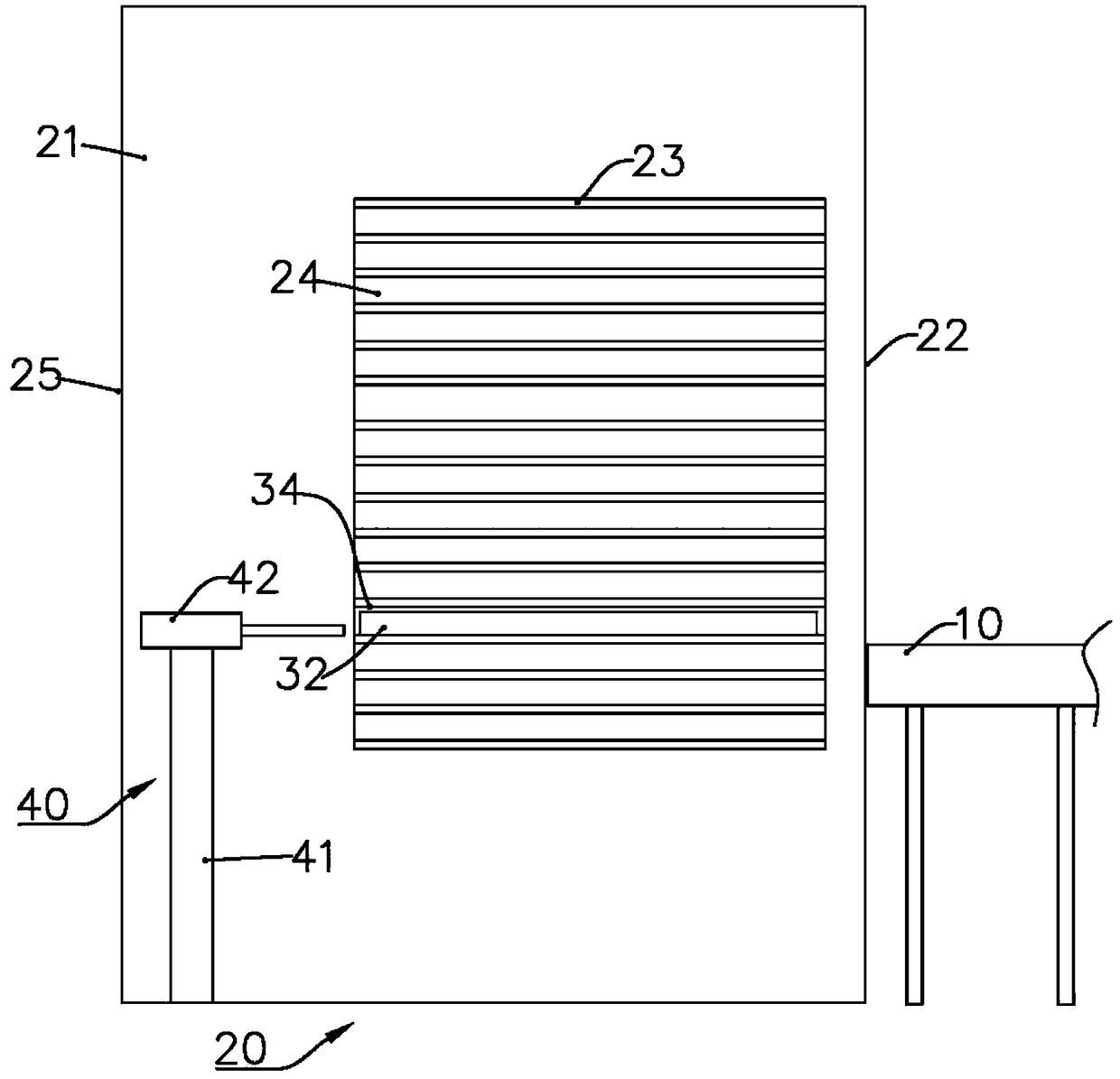

[0042] The chemical production equipment in this embodiment includes a transport assembly 10 and an oven 20 .

[0043] Such as Figure 2 to Figure 5 As shown, the oven 20 is connected to the transfer assembly 10 . Wherein, the oven 20 includes a box body 21 , the box body 21 includes a door body 22 , and a frame body 23 is arranged inside the box body 21 , and the frame body 23 has a multi-layer compartment 24 for placing the tray body 30 . The tray body 30 is used for loading materials to be dried.

[0044] The box body 21 has a rear wall 25, and the position between the rear wall 25 and the frame body 23 is provided with a removal assembly 40. The removal assembly 40 includes a lift unit 41, and the lift unit 41 is provided with a lateral push unit 42. The lateral push unit 42 Used to push the tray 30 placed on the compartment 24 onto the transfer assembly 10 . The lifting unit 41 may specifically be a screw, which is driven by a motor, thereby driving the horizontal push...

no. 2 example

[0052] The chemical production equipment of this embodiment is basically the same as that of the above-mentioned first embodiment, and only the differences will be described in detail below.

[0053] Such as Figure 6 and Figure 7 As shown, the door body 22 of this embodiment has an opening 26 , and a push-pull assembly 50 is disposed on the top of the opening 26 , and the push-pull assembly 50 includes a push-pull unit 51 and a shielding board 52 . The push-pull unit 51 is, for example, an air cylinder or a hydraulic cylinder to push the telescopic rod to move, thereby driving the shielding plate 52 to shield or open the opening 26 . In the open state, the tray body 30 can enter or leave the box body 21 driven by other components, and in the closed state, the drying operation can be performed in the box body 21 .

[0054] The working method includes the following steps: the push-pull unit 51 drives the shielding plate 52 to move in the vertical direction, and the shielding...

no. 3 example

[0056] The chemical production equipment of this embodiment is basically the same as that of the above-mentioned first embodiment, and only the differences will be described in detail below.

[0057] Such as Figure 8 As shown, the transmission assembly 10 of this embodiment includes a support unit 11, a lifting mechanism 12 is provided at the lower part of the support unit 11, and the support unit 11 includes a plurality of rotating rollers 13 arranged in sequence, and the rollers 13 are used to transport the disk 30 . The lifting mechanism 12 is preferably a motor-driven screw structure, and the screw drives the support unit 11 to move in the vertical direction, so that the upper surface of the support unit 11 corresponds to the disc body 30 that is pushed out of the box body 21, so that it is pushed out The disc body 30 moves onto the support unit 11 . In addition, the height of the support unit 11 can also be manually adjusted, so that the height of the pushed out tray b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com