Saturated steam valve

A valve and steam technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of poor sealing, medium leakage, short life, etc., achieve excellent temperature resistance and corrosion resistance, and small hard seal joint surface , the effect of good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

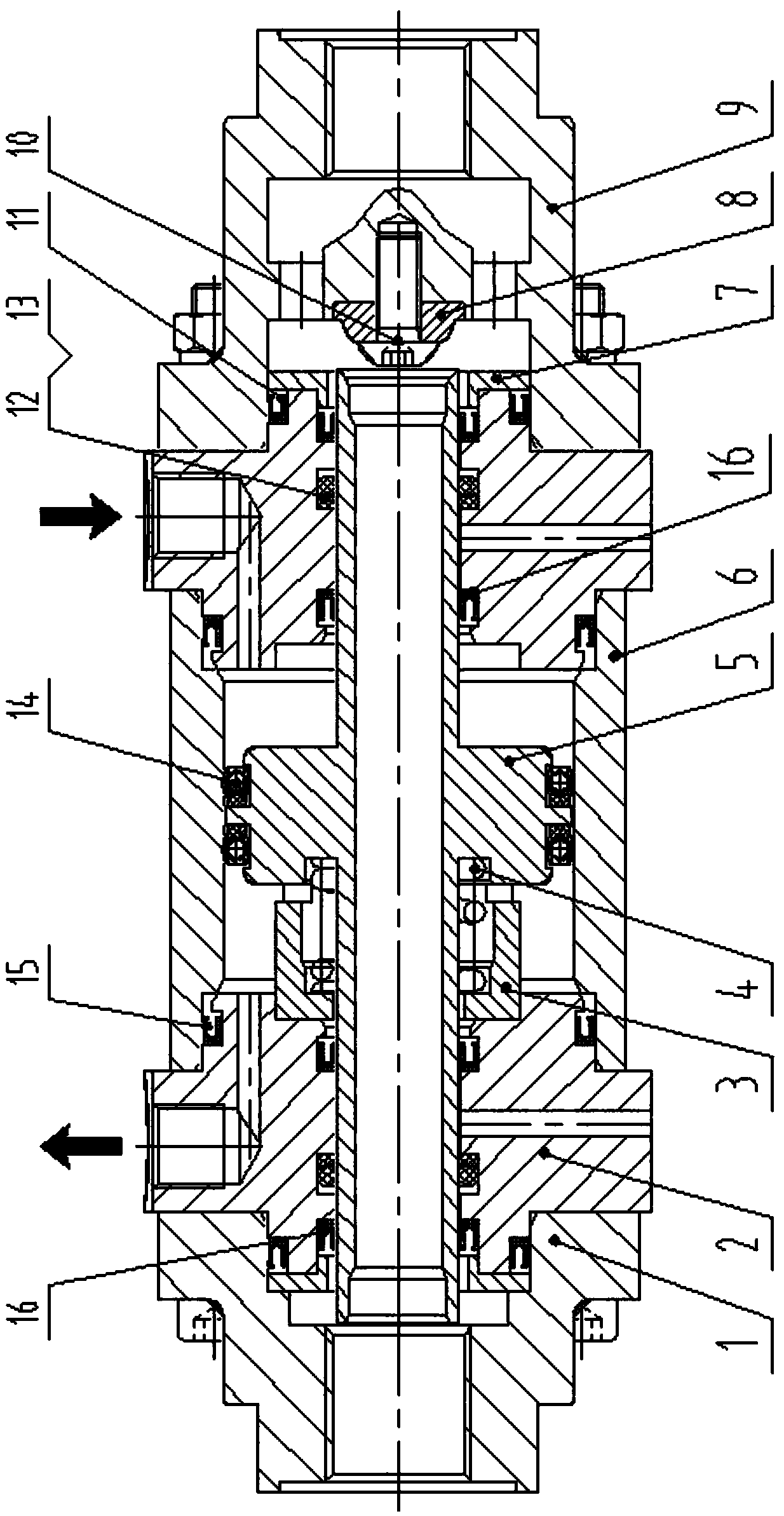

[0022] Attached below Figure 1-3 The specific embodiment of the present invention will be further described.

[0023] A valve for saturated steam, including a left end cover 1, a bushing 2, a spool 5, a cylinder 6 and a right end cover 9; a spool 5 is slidably installed in the cylinder 6 through a second pan seal 14, and the left side of the spool 5 A spring 4, a spring seat 3, a bushing 2, and a left end cap 1 are installed in turn, and the valve core 5 is duplex stainless steel, and the right side of the valve core 5 is successively fitted with a bushing 2 and a right end cap 9; the bushing 2 and the cylinder barrel 6 Fitting through the spigot and sealing with the third vari-seal 15, sealing between the bush 2 and the valve core 5 through the fourth vari-seal 16 and O-ring 12, both sides of the bush 2 are provided with a fourth vari-seal Seal 16, the O-ring 12 is located between the two fourth pan-seals 16, one side of the O-ring 12 is provided with a retaining ring 13, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com