Negative-Poisson ratio structure-based self-adaptive principal axis preload adjusting method

An adaptive adjustment, negative Poisson's ratio technology, used in bearing components, shafts and bearings, special data processing applications, etc. Quick response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] A method for adaptively adjusting spindle preload based on a negative Poisson's ratio structure, comprising the following steps:

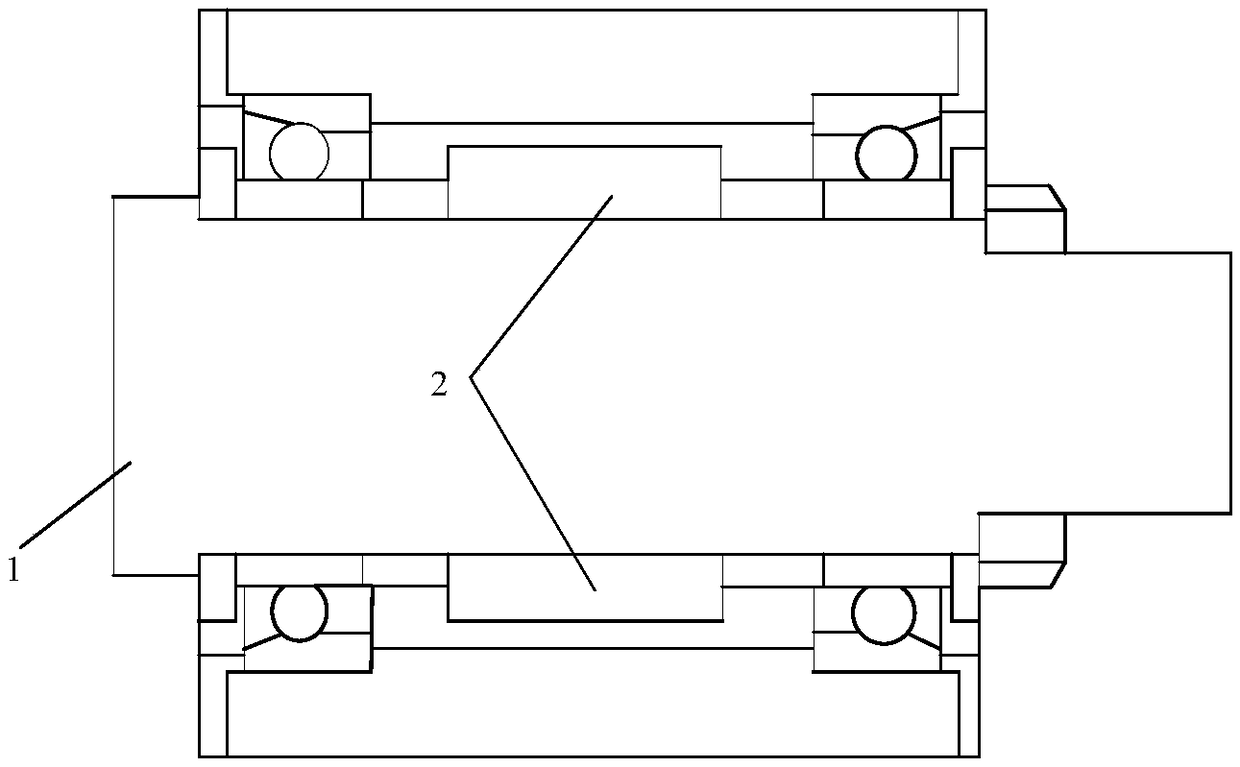

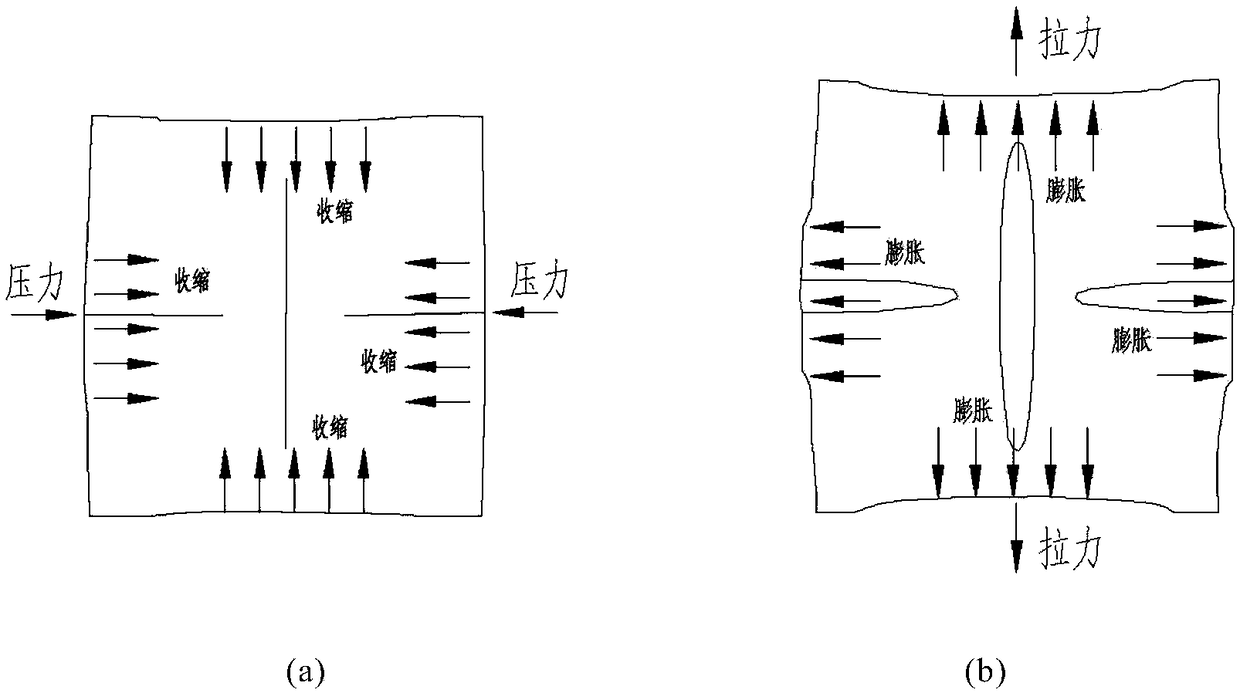

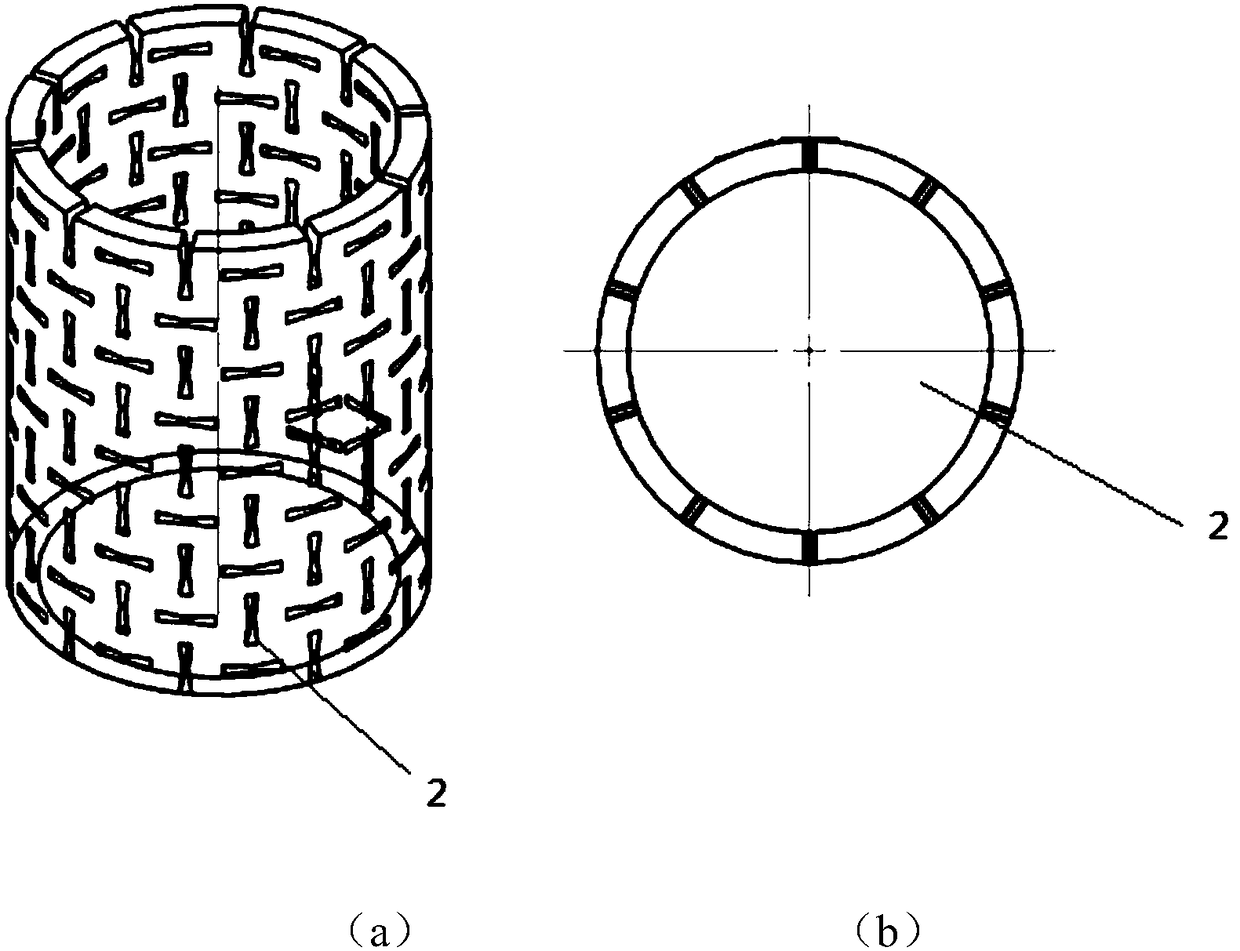

[0018] Step 1. Refer to figure 1 , the bearing inner ring spacer 2 adopts a negative Poisson’s ratio structure, which is a three-dimensional thin-walled cylindrical negative Poisson’s ratio structure, and the cylinder wall is covered with periodic through holes that can achieve low porosity, such as image 3 Shown is a concave hexagon; the inner ring spacer 2 of the bearing will deform axially under the action of centrifugal force, and the deformation is proportional to the centrifugal force, so that the self-adaptive adjustment of the preload at different speeds can be realized.

[0019] Step 2. In the initial assembly and low-speed stages, the bearing inner ring spacers 2 of the negative Poisson’s ratio structure are all under p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com