Low-speed high-load excavating construction machine with butter distribution

A construction machinery, low-speed technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve problems such as falling off, and achieve the effect of improving the service life and the flexibility of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

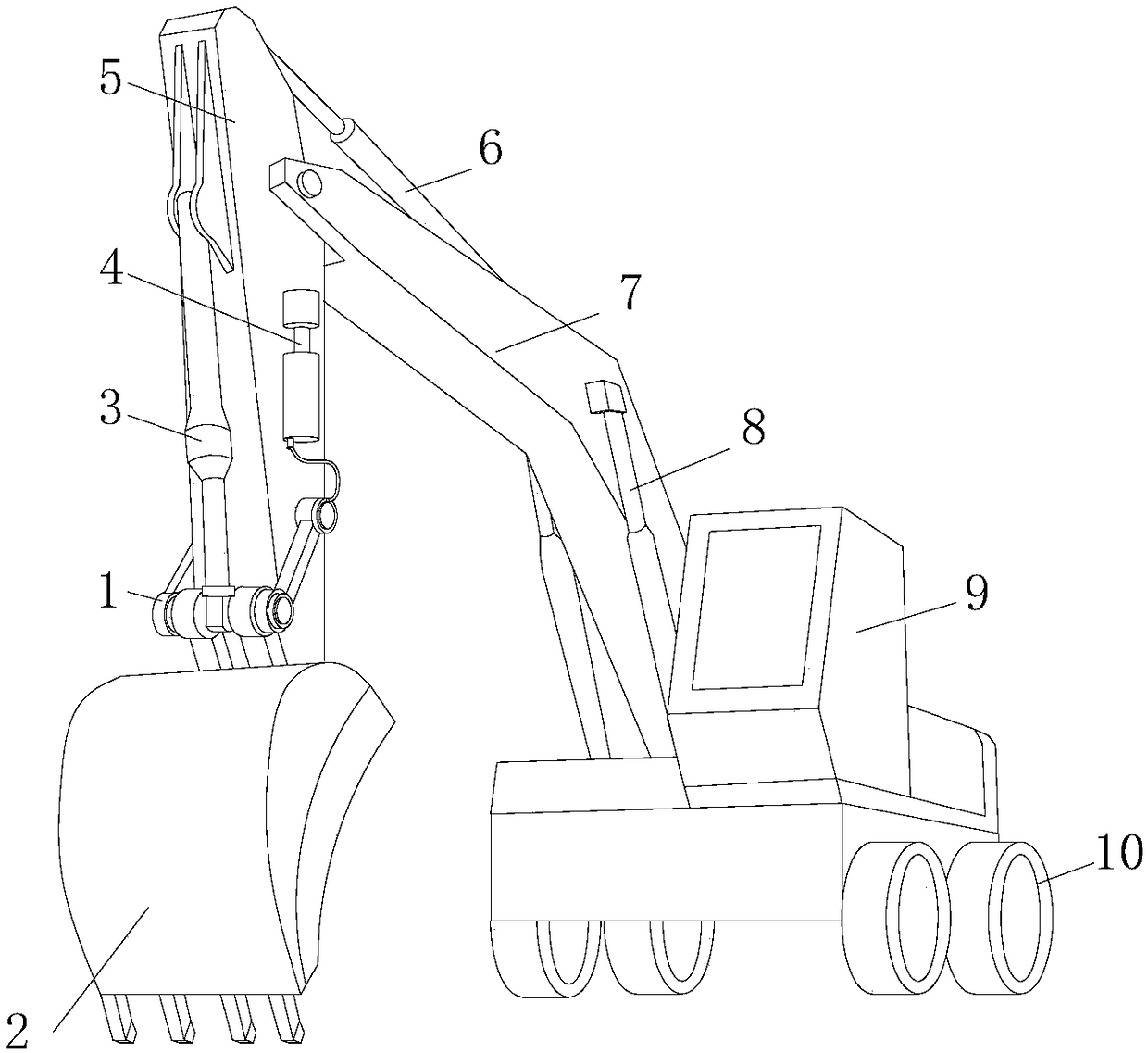

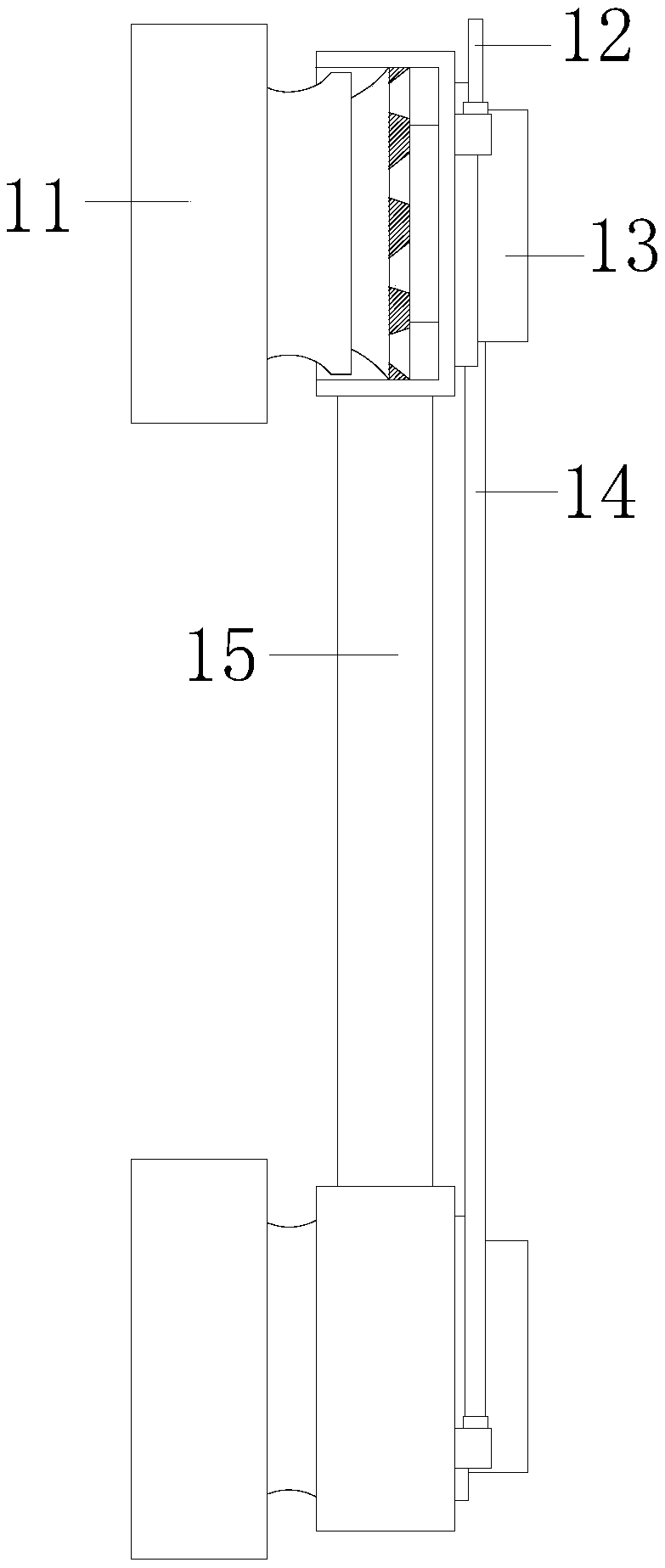

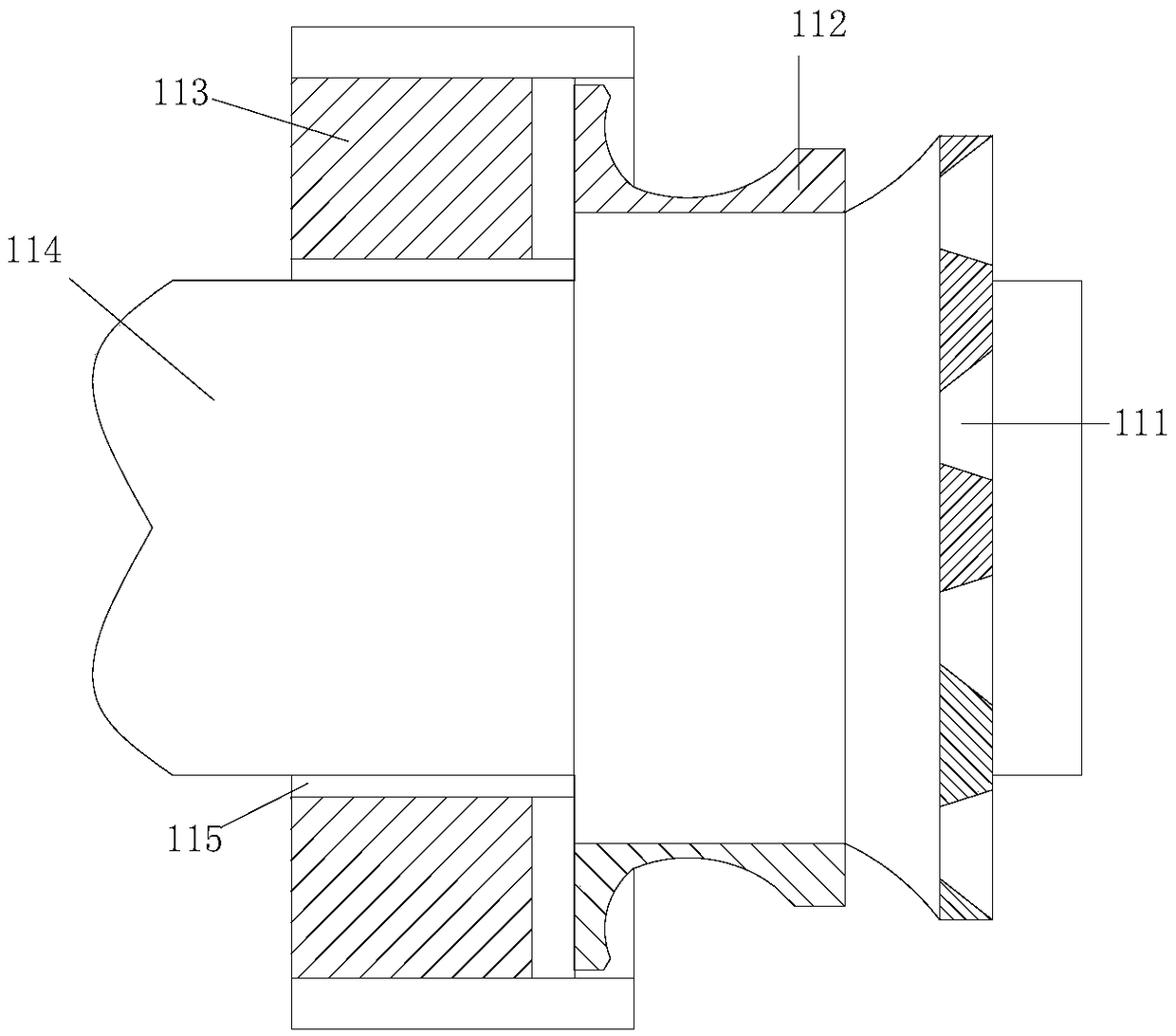

[0026] Such as Figure 1-Figure 7 As shown, the present invention provides a low-speed and high-load excavation construction machine with butter distribution. Rod 6, boom 7, boom driving rod 8, control body 9, moving wheel 10, the lubricating arm 1 is provided with two and evenly fixed on both sides of the movable shaft at the top of the bucket 2, the shovel arm control rod 3. The end of the bottom is fixed in the middle of the bucket 2. The bottom of the oil reservoir 4 is connected to the oil valve of the lubricating arm 1 through an oil pipe. connected, the boom driving rod 8 is provided with two and the movable ears on the top are fixed on the left and right sides of the boom 7 by bolts, and the bottom of the control body 9 is provided with four moving wheels 10, and the storage The coil at the top of the oiler 4 is connected with the circuit inside the control body 9 through wires. The internal structure of the lubricating arm 1 includes: a shunt sleeve 11, an oil valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com