Fermentation method for improving yield of bacillus subtilis antibacterial protein

A technology of Bacillus subtilis and Bacillus subtilis is applied in the field of fermentation to improve the yield of Bacillus subtilis antibacterial protein, and can solve the problems of immature industrial application, incomplete promotion of drugs, unclear characteristics and mechanism of action, etc., and achieve stable yield , the effect of saving costs and improving production levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

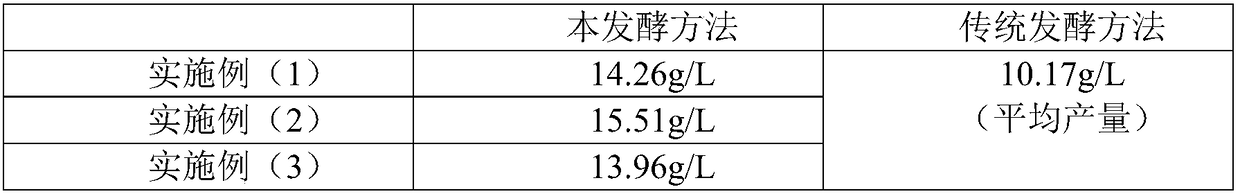

Examples

Embodiment 1

[0042] S1. Purchase the strain of Bacillus subtilis, the number of which is BNCC 189983, which is preserved by BNCC Biotechnology Co., Ltd. (BNCC). Inoculate the Bacillus subtilis strain on the slant and cultivate it in a constant temperature incubator at 37°C, then prepare a bacterial suspension with a concentration of 5,000,000 cells / ml from the activated strain on the slant medium, and inoculate it in a fresh In the seed medium of 36°C, shake culture on a shaker at 180r / min.

[0043] S2. Inoculate the fermented strain BNCC 189983 Bacillus subtilis to nutrient components (according to mass percentage) as glucose 1.0%, peptone 1.0%, NaCl 1.0%, KH 2 PO 4 0.15%, MgSO 4 ·7H 2 O 0.15%, the rest of the water in the seed medium was cultivated for 12 hours to obtain a seed liquid, the culture temperature was 36° C., and the initial pH value of the medium was 7.0.

[0044] S3. Inoculate the seed solution of the strain producing the Bacillus subtilis BNCC 189983 antibacterial pro...

Embodiment 2

[0052] S1. Purchase the strain of Bacillus subtilis, the number of which is BNCC 189983, which is preserved by BNCC Biotechnology Co., Ltd. (BNCC). Inoculate the Bacillus subtilis strain on the slant and cultivate it in a constant temperature incubator at 37°C, then prepare a bacterial suspension with a concentration of 5,000,000 cells / ml from the activated strain on the slant medium, and inoculate it in a fresh In the seed medium of 37 ° C, 200 r / min shaking on the shaker culture.

[0053] S2. Inoculate the fermented strain BNCC 189983 Bacillus subtilis to nutrient components (according to mass percentage) as glucose 1.0%, peptone 1.0%, NaCl 1.0%, KH 2 PO 4 0.15%, MgSO 4 ·7H 2 O 0.15%, the rest of the water in the seed medium was cultivated for 14 hours to obtain a seed solution, the culture temperature was 37° C., and the initial pH value of the medium was 7.0.

[0054] S3. Inoculate the seed liquid of the strain producing the Bacillus subtilis BNCC 189983 antibacterial...

Embodiment 3

[0062] S1. Purchase the strain of Bacillus subtilis, the number of which is BNCC 189983, which is preserved by BNCC Biotechnology Co., Ltd. (BNCC). Inoculate the Bacillus subtilis strain on the slant and cultivate it in a constant temperature incubator at 37°C, then prepare a bacterial suspension with a concentration of 5,000,000 cells / ml from the activated strain on the slant medium, and inoculate it in a fresh In the seed medium of 38 ° C, 220 r / min shaking on the shaker culture.

[0063] S2. Inoculate the fermented strain BNCC 189983 Bacillus subtilis to nutrient components (according to mass percentage) as glucose 1.0%, peptone 1.0%, NaCl 1.0%, KH 2 PO 4 0.15%, MgSO 4 ·7H 2 O 0.15%, the rest of the water in the seed medium was cultivated for 16 hours to obtain a seed solution, the culture temperature was 37° C., and the initial pH value of the medium was 7.0.

[0064] S3. Inoculate the seed liquid of the bacteria producing the Bacillus subtilis BNCC 189983 antibacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com