Tug tail cable lifting device

A tugboat and tail towing technology, applied in the direction of towing/push equipment, transportation and packaging, ship parts, etc., can solve the problems of tail towing cable weight, danger, etc., achieve the effect of improving work efficiency, simple structure, and avoiding human operation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

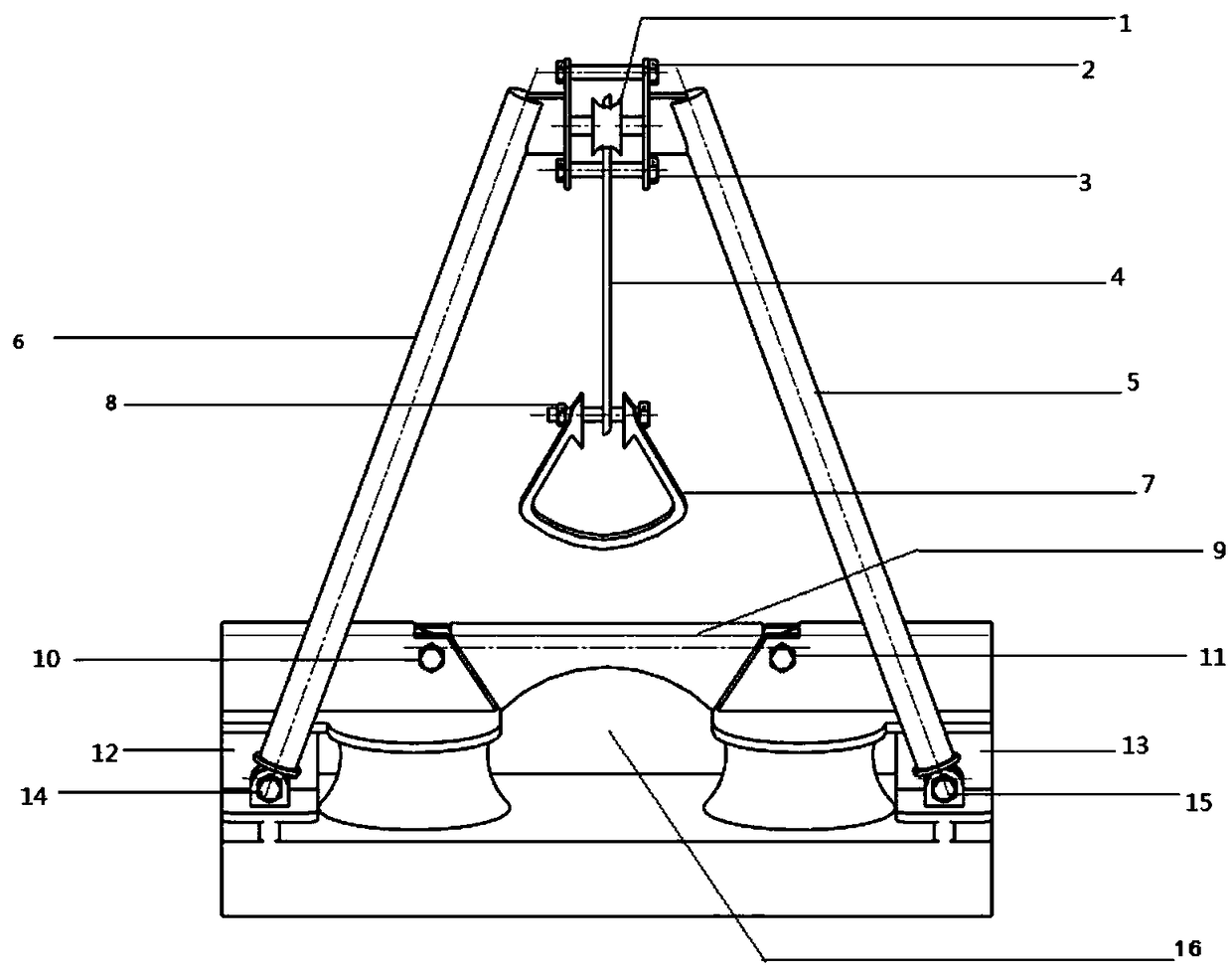

[0012] A kind of tugboat stern tow cable hoisting device, dumb mouth 9) and special-purpose fairlead 16 are original devices on the back side of the tugboat; figure 1 As shown, symmetrical left bracket base 12 and right bracket base 13 are welded at the side of the boat position on both sides of special fairlead 16, and left bracket base 12 and right bracket base 13 are respectively provided with bolt holes; the bottom of left bracket 6 and right bracket 5 The ends are respectively hinged on the left bracket base 12 and the right bracket base 13 through through bolts 5 14 and 6 through bolts 15, and when they need to be erected, the tops of the left bracket 6 and the right bracket 5 are connected by through bolts 1 2 and 2 through bolts 3 Form tripod support, the length of left support 6 and right support 5 is 2 meters, and its purpose is that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com