Cutting device for joss paper processing

A cutting device and paper money technology, applied in metal processing, etc., can solve the problems of excessive loss of raw material paper, slow processing speed, and uneven paper money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

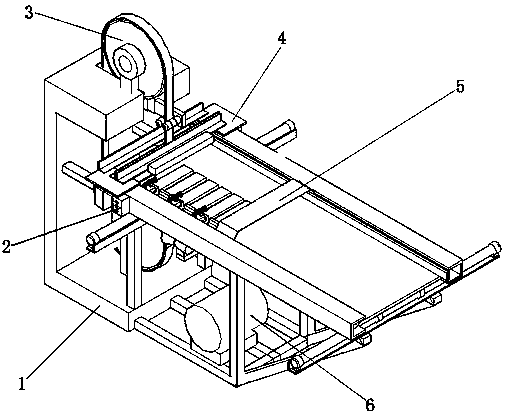

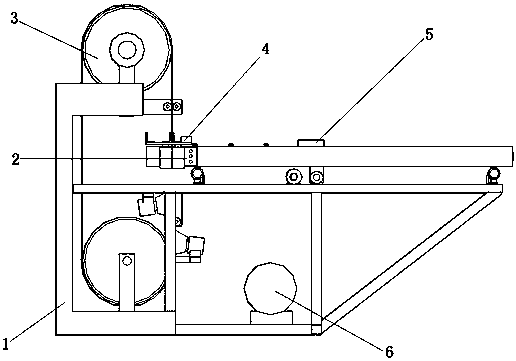

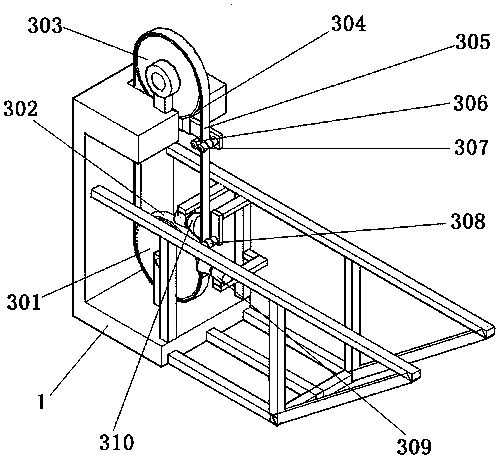

[0025] The specific implementation, structure, features and functions of the paper money processing and cutting device according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0026] see Figure 1 to Figure 8 , a paper money processing and cutting device of the present invention includes a frame 1, a switch 2, a cutting mechanism 3, a left and right moving mechanism 4, a front and rear moving mechanism 5, and a motor A6, and is characterized in that: the cutting mechanism 3 is composed of a runner A301, Retaining ring A302, runner B303, retaining ring B304, blade 305, positioning roller A306, positioning roller B307, positioning roller C308, knife sharpener A309, knife sharpener B310, and the lower part of the frame 1 is equipped with a runner A301 through the bearing seat , a retainer A302 is installed on the runner A301, a runner B303 is installed through the bearing seat above the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com