Cylinder concave screen type threshing system with anti-winding and anti-clogging functions

A concave plate screen and anti-clogging technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of threshing drum winding and clogging, affecting work efficiency, and the harvester not working properly, avoiding clogging and optimizing threshing. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

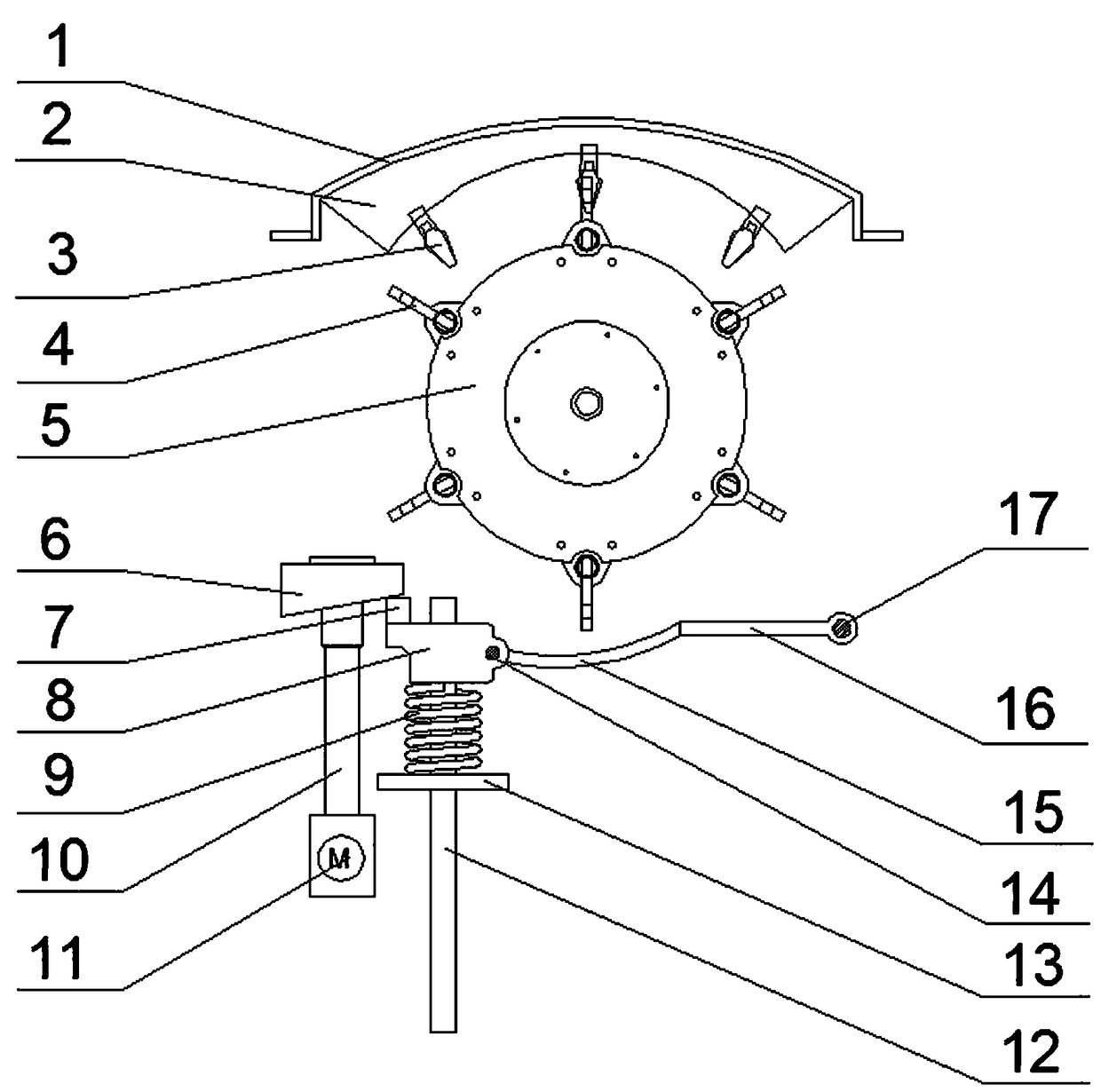

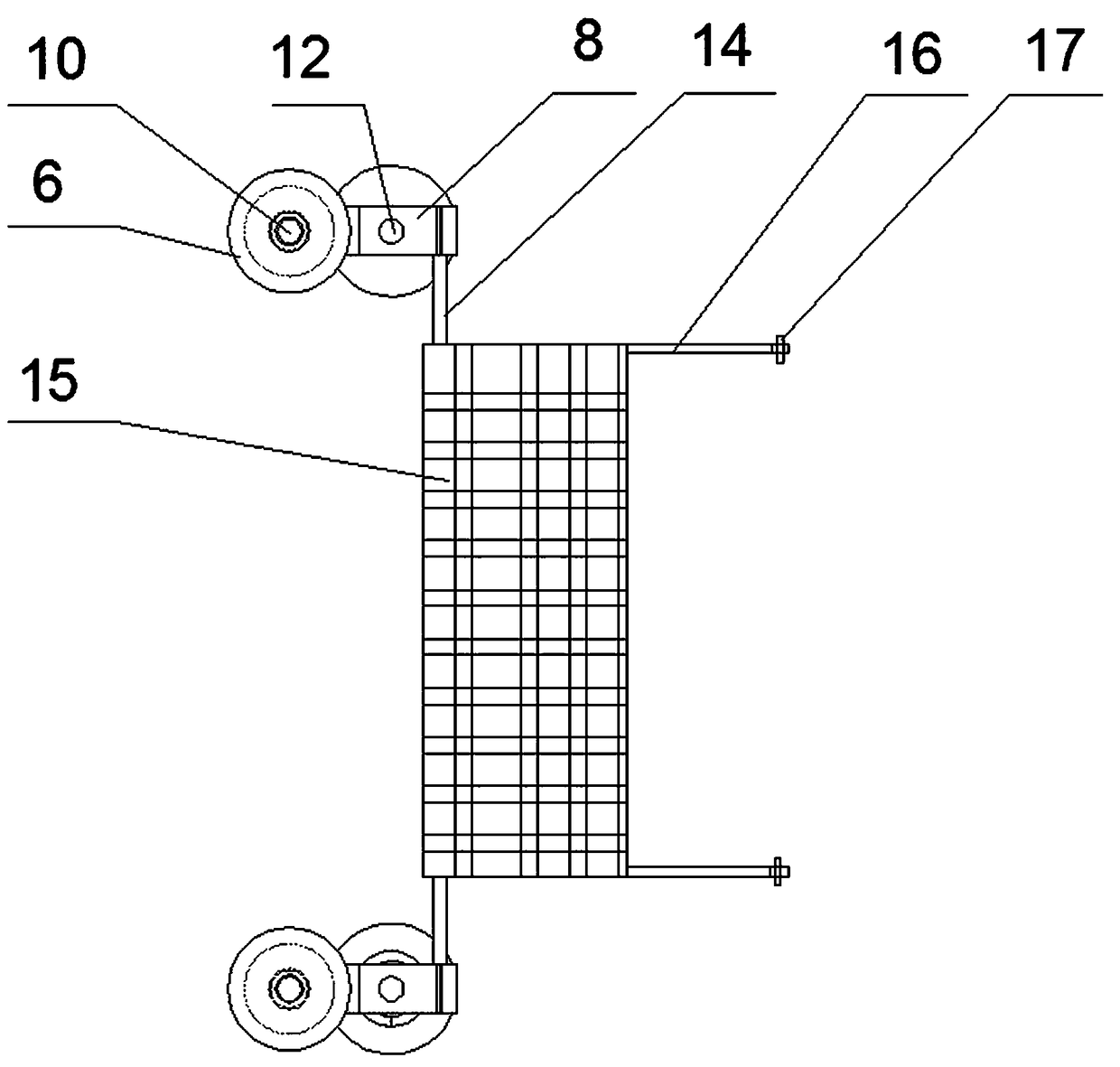

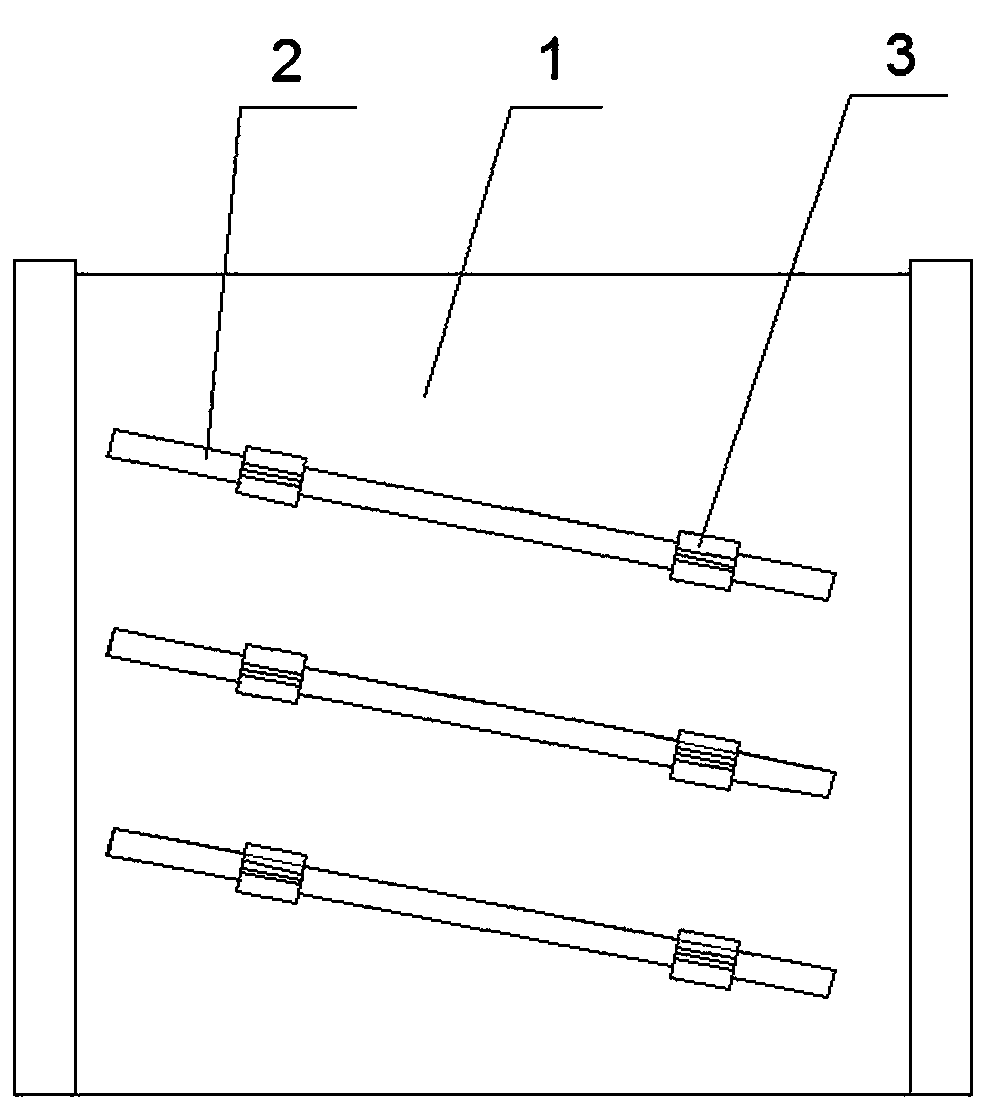

[0018] Such as Figure 1 to Figure 3 As shown, a drum sieve type threshing system with anti-winding and anti-clogging functions of the present invention is similar to conventional drum sieve type threshing systems, and both include a frame on which a Distributed threshing drums 5 and the driving device for driving the drums to rotate at high speed, arc-shaped cover plate 1 is arranged on the upper edge of the threshing drum 5 on the frame, and a grid is arranged on the lower edge of the threshing drum 5 on the frame The concave screen 15 performs threshing through the action of combing and brushing between the nail teeth 4 distributed on the drum and the grid concave screen 15 .

[0019] Different from the conventional drum concave screen type threshing system, the present invention also includes an anti-clogging mechanism for adjusting the gap between the grid concave screen 15 and the threshing drum 5 and for winding the stems wound on the threshing drum 5 The stalks are sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com