Electrolytic nickel (ALLOY) plating solution

A plating solution and electrolytic nickel technology, applied in circuits, electrical components, printed circuits, etc., can solve problems such as insufficient filling of tiny holes, tiny recesses, insufficient filling of electrolytic nickel plating solution, and cracks in precipitates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 4、 comparative example 1 to 3

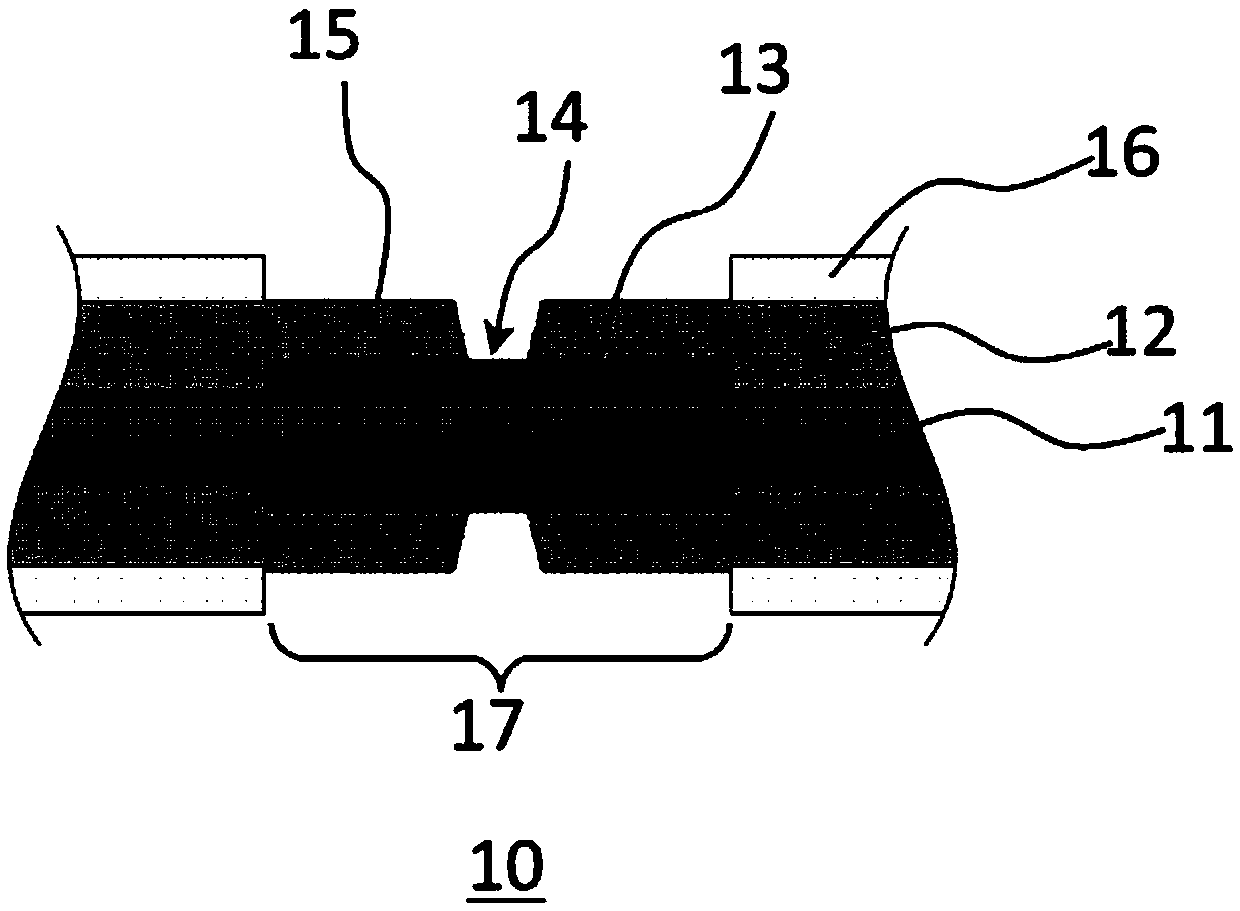

[0101] A 12 mm square evaluation printed circuit board (manufactured by Nippon Circuit Co., Ltd.) having a laser hole with an aspect ratio of 0.88 (φ45 μm×40 μmD) was used as a model of the minute concave portion.

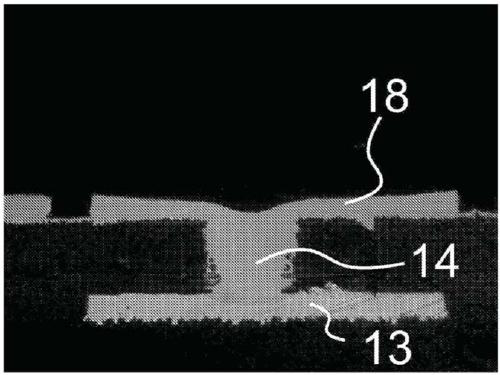

[0102] A sectional view of the periphery 10 of the plated portion is shown in figure 1 . Copper foil 13 with a thickness of 12 μm is attached to the through-hole forming part of the base material 11 made of BT (Bismaleimide-triazine) with a thickness of 0.4 mm, and a prepreg with a thickness of 60 μm is laminated thereon. After prepreg type build-up resin (build-up resin) 12, a blind via hole (blind via hole) with a diameter of 45 μm and a depth of 40 μm (hereinafter also referred to as “via hole” and “ In the case of a "via" 14, a seed layer 15 of about 1 μm is formed on the outer surface of the substrate (the surface of the build-up resin 12) and the inner wall of the through hole 14 by electroless copper plating.

[0103] Furthermore, it is formed by dry film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com