A flexible board with high reliability and an assembly system thereof

A flexible board and reliability technology, which is applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, and electrical components. It can solve problems affecting the welding of other components and improve assembly and welding. Efficiency, Prevention of Welding Position Shift, Effect of Strengthening Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

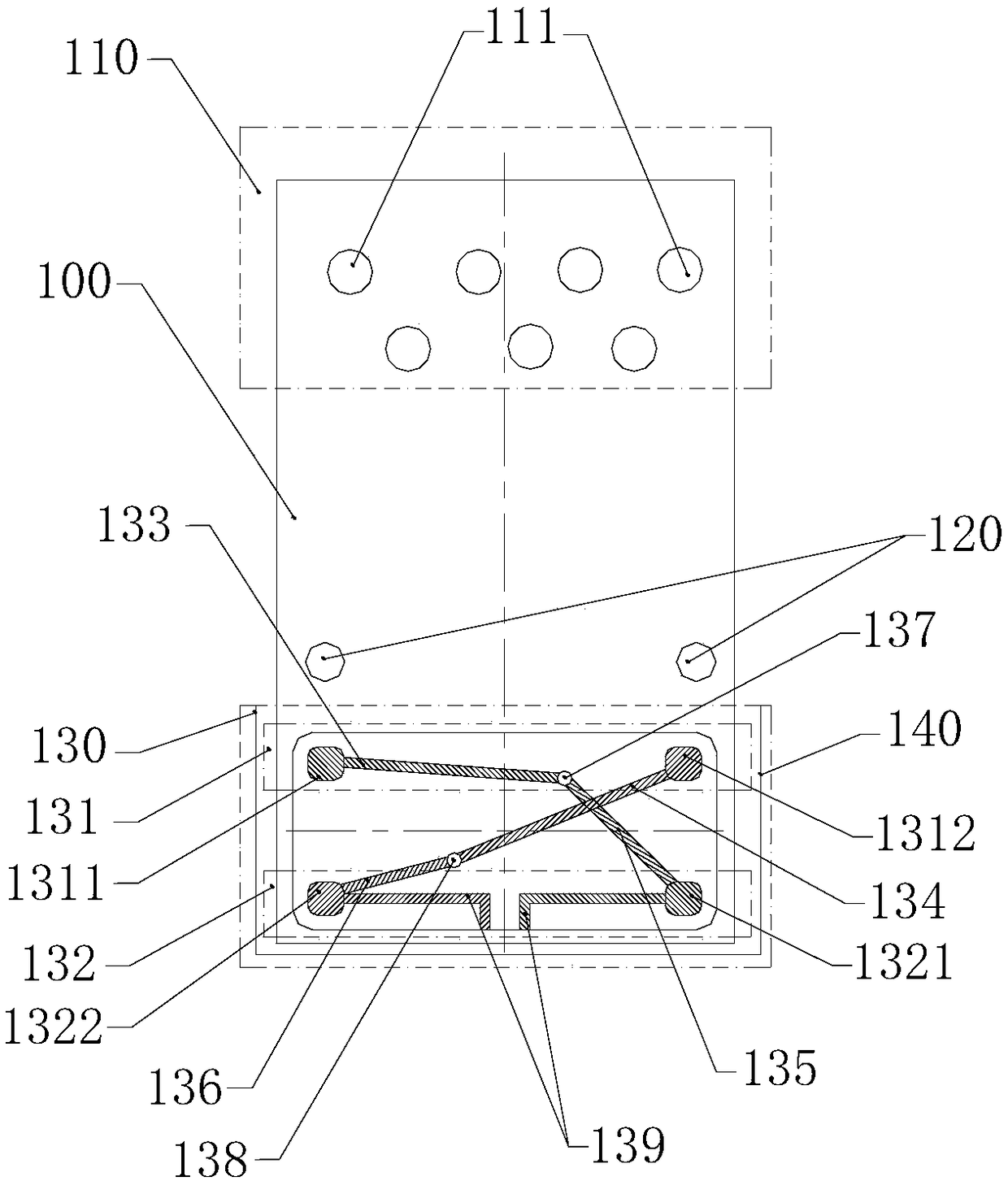

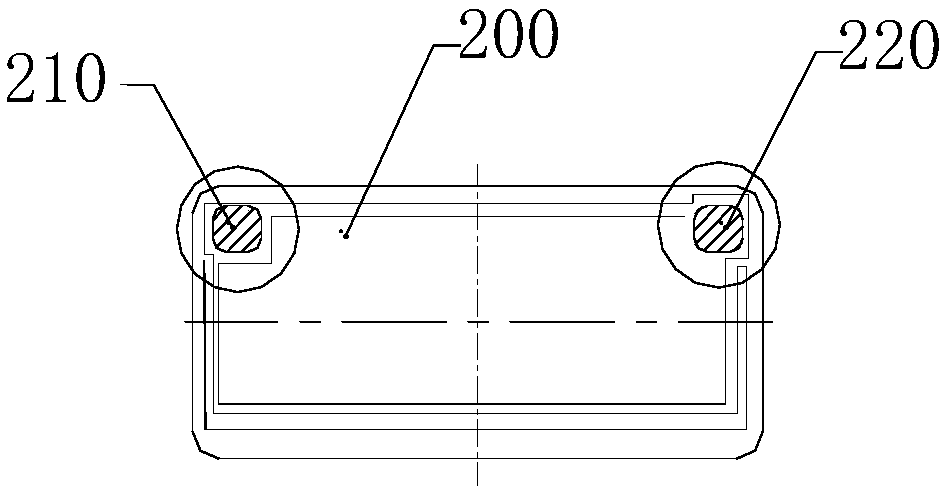

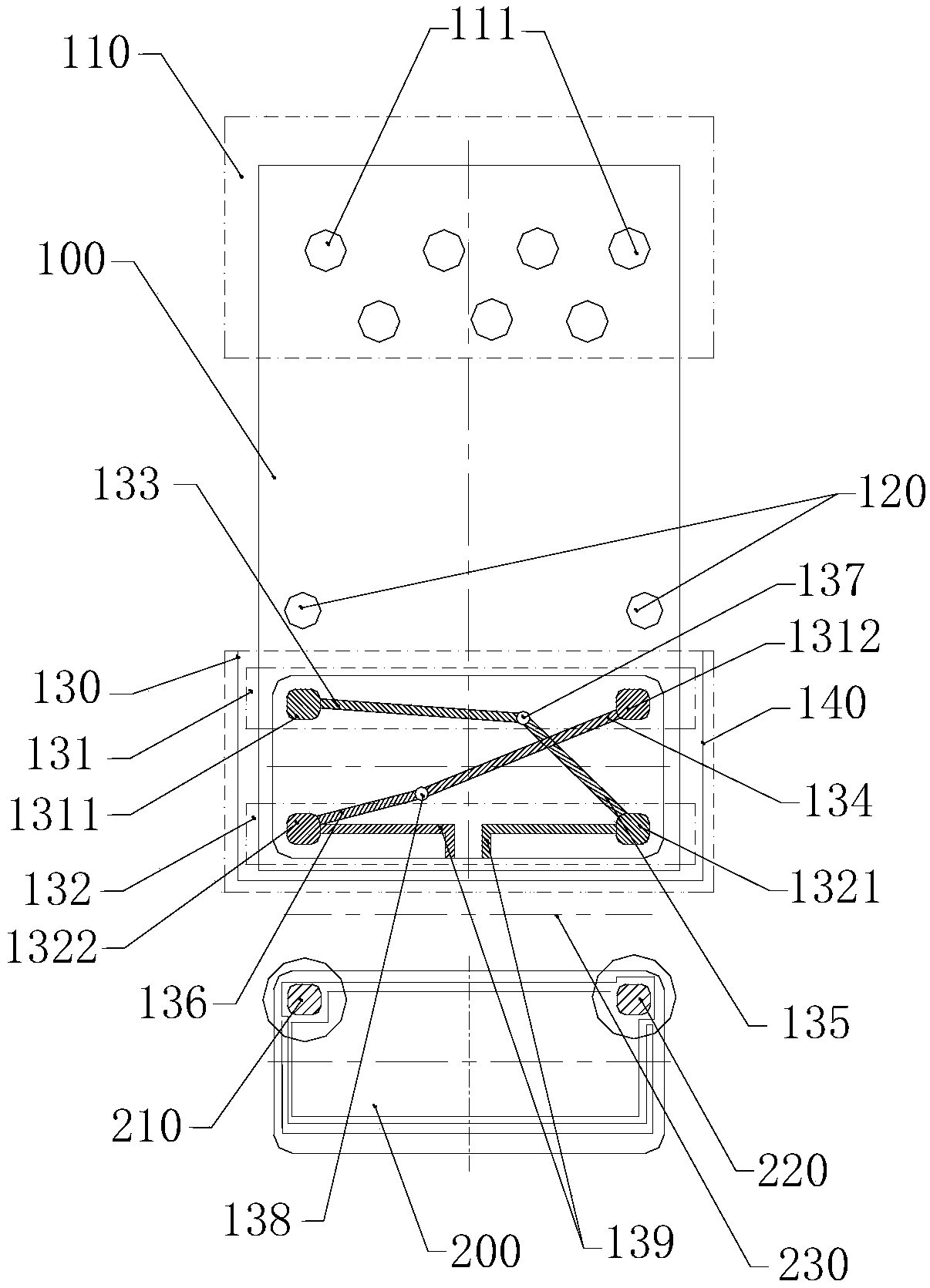

[0032] Such as figure 1 As shown, a flexible board with high reliability includes a flexible board body 100, a main via area 110, a standard pad area 130 and a pair of positioning holes 120, the main via area 110 and the standard pad Areas 130 are respectively provided at both ends of the flexible board body 100, a pair of positioning holes 120 are close to the standard pad area 130, and a pair of positioning holes 120 are along the vertical center of the flexible board body 100 Line symmetry; in the main via area 110, a set of main vias 111 corresponding to the electrical network of the optical device pin to be manufactured or tested are provided; in the standard pad area 130, a A set of standard pads correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com