Device and method for measuring the loading depth of functional groups on the channel surface of modified porous materials

A technology of surface functional groups and porous materials, which is applied in the field of devices for measuring the loading depth of functional groups on the surface of modified porous materials, can solve the problems of expensive instruments, many restrictions on porous materials and modified functional groups, and complicated operations, and can reduce the time and cost. The effect of cost consumption, simple operation steps, and less restriction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

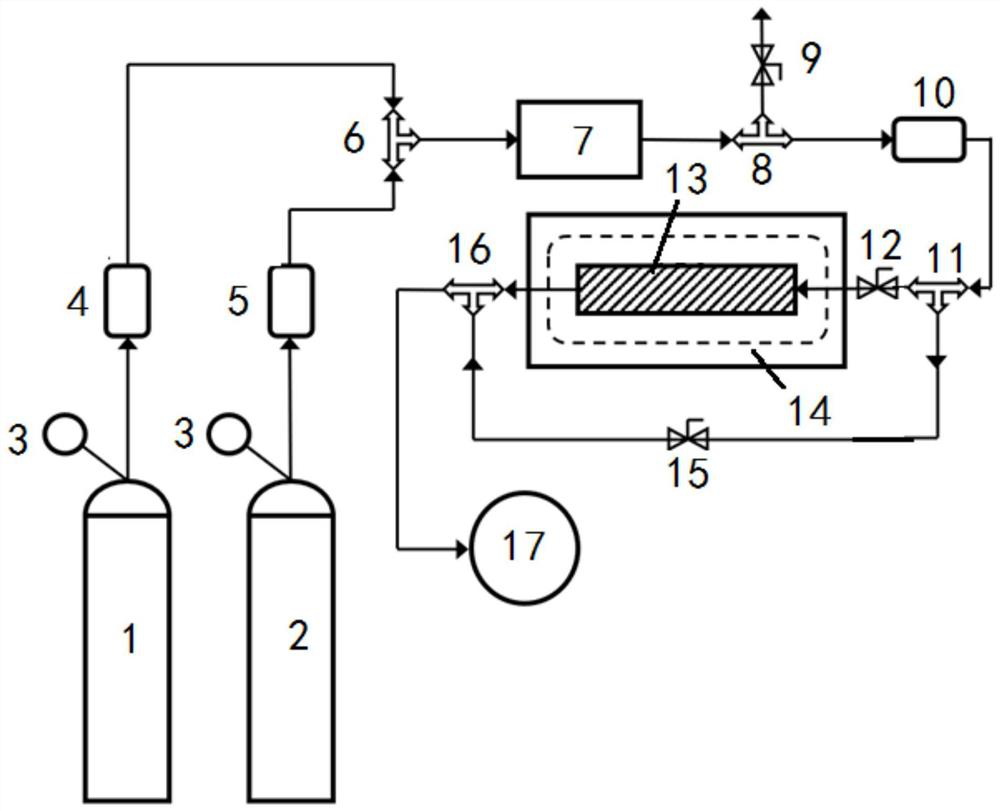

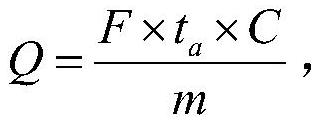

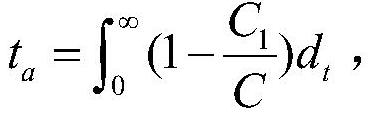

[0035] A device for measuring the loading depth of functional groups on the channel surface of modified porous materials, the structure of which is as follows: figure 1 As shown, it includes a gas mixing chamber 7 connected in sequence, a packed column 13 for filling the modified porous material to be measured, and a gas analyzer 17 for analyzing the gas concentration, wherein the inlet of the gas mixing chamber 6 is connected with high-purity nitrogen gas The device 2 is connected with the gas generator 1 to be tested, the outlet of the gas generator 1 to be tested is equipped with a pressure reducing valve 3, and the first flow regulator 4 is installed on the pipeline, and finally leads to an inlet of the first three-way valve 6, The outlet of the high-purity nitrogen generator 2 is equipped with a pressure reducing valve 3, and a second flow regulator 5 is installed on the pipeline, which finally leads to another inlet of the first three-way valve 6, and the outlet of the fi...

Embodiment 2

[0048] Adopt the device identical with embodiment 1, concrete operation is as follows:

[0049] 0.5 g of the amine-modified porous material was placed in a packed column with a length of 0.5 cm and an inner diameter of 0.7 cm. Both ends of the packed column were tightly plugged with silanized glass wool and placed in a thermostatic control box. The gas mixing box is connected upstream of the packed column, and the two gas inlets of the gas mixing box are respectively connected to high-purity nitrogen and 100ppm SO 2 gas. Connect the downstream of the packed column to SO 2 Gas analyzer, which can monitor SO online in real time 2 concentration. do SO 2 Before the adsorption experiment, under the condition of 80°C, high-purity nitrogen gas was passed into the packed column at a flow rate of 300mL / min for 1 hour to fully remove the impurities adsorbed by the amine-based modified porous material. After passing high-purity nitrogen for 1 hour, under the condition of 25°C, flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com