Steel structure bolt loosening detection robot

A bolt loosening and robot technology, applied in instruments, manipulators, measuring devices, etc., can solve the problems of unsupported detection environment and poor results, and achieve the effect of reducing the risk of manual detection and improving the detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

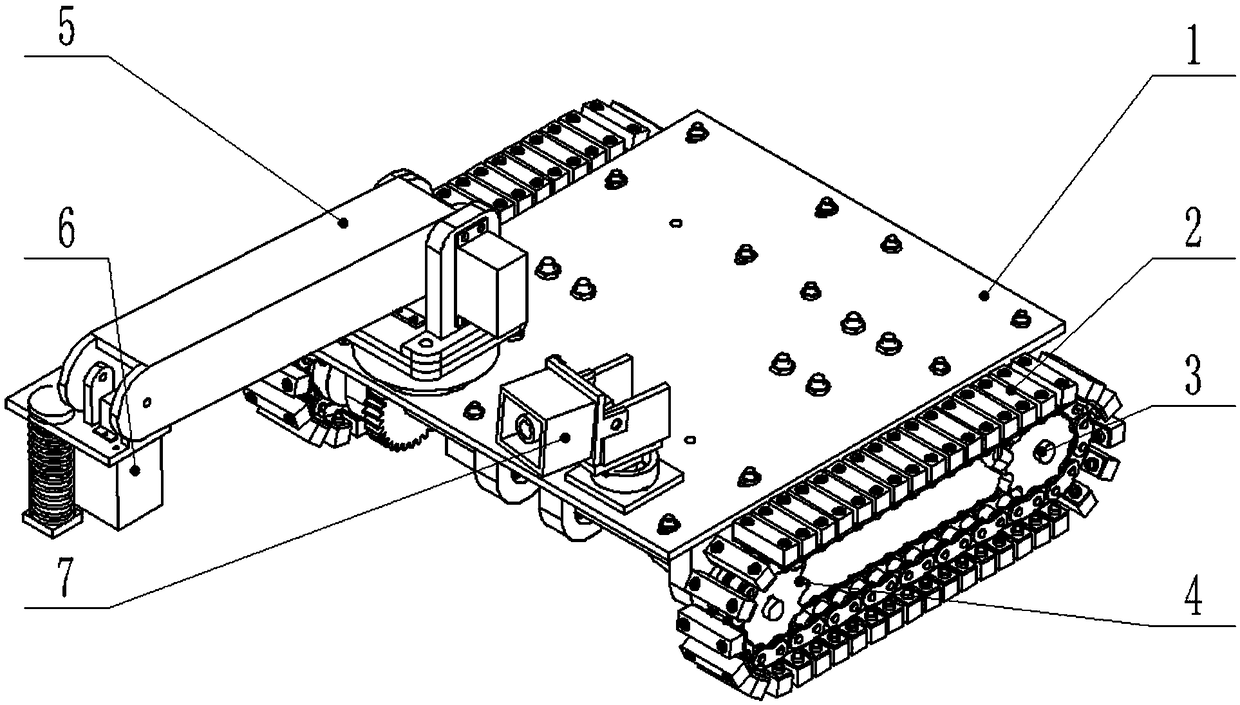

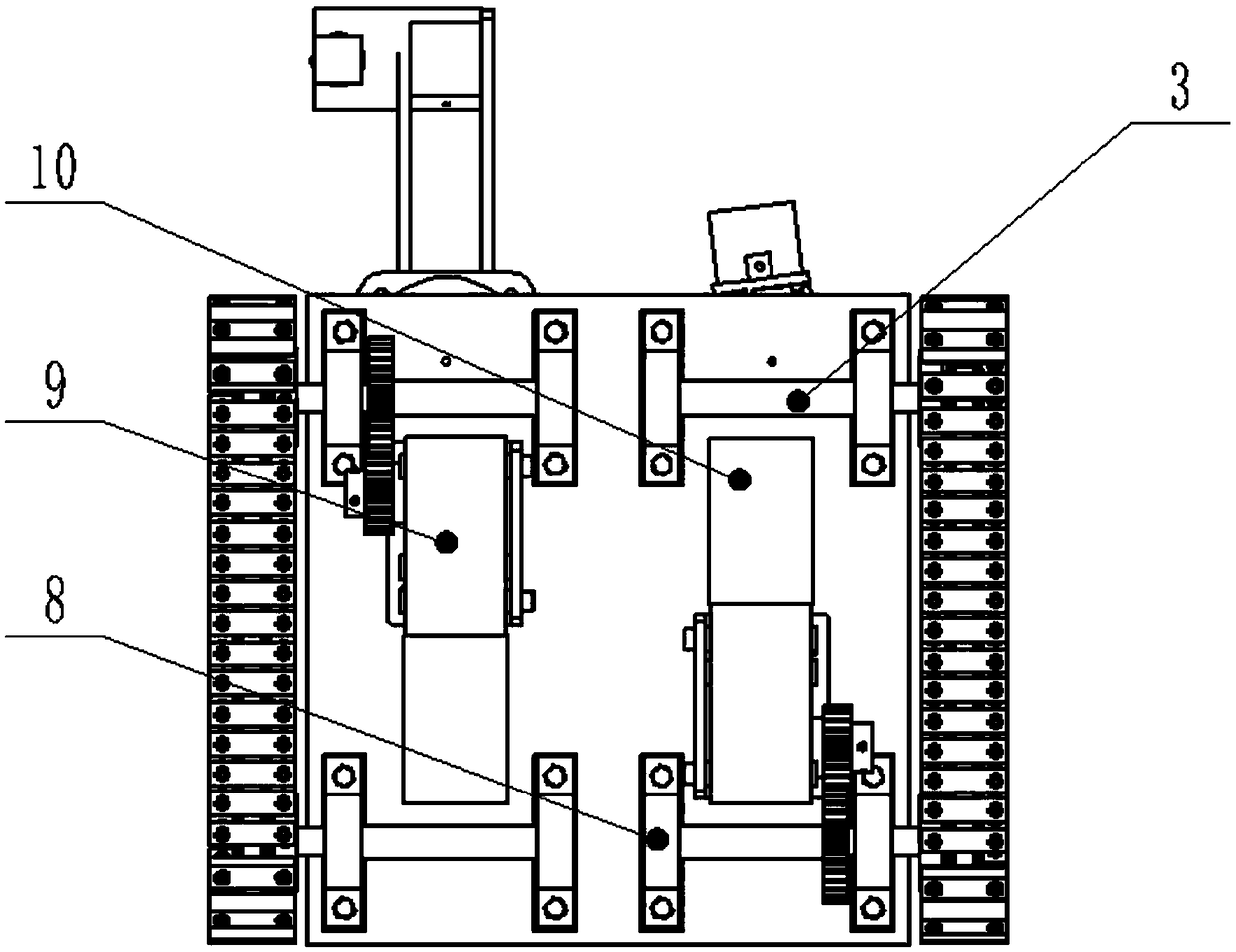

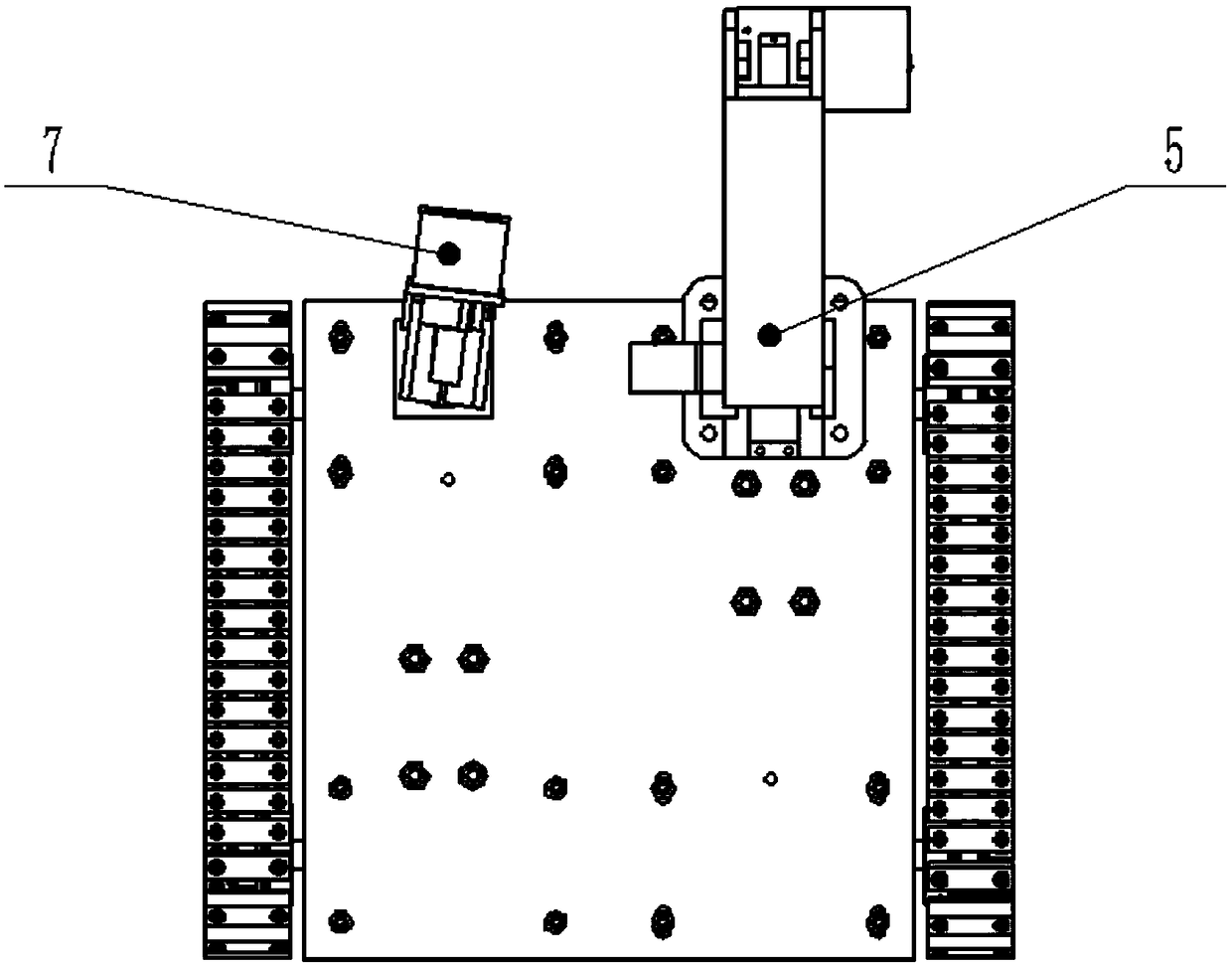

[0027] Such as Figure 1 to Figure 7 As shown, a steel structure bolt loose detection robot includes a detection end 6, a multi-degree-of-freedom mechanical arm 5 and a walking device, and the detection end 6 is installed on the walking device through the multi-degree-of-freedom mechanical arm 5, and the walking device is The position adjustment of the detection terminal 6 provides a walking function, and the detection terminal 6 includes a substrate 20, a spring 30, a magnetic table seat adsorption device and two piezoelectric ceramic sheet sensors, and the spring 30 and the magnetic table seat adsorption device are fixed on the bottom of the substrate 20 side by side. Wherein the first piezoelectric ceramic sensor 17 is fixed on the bottom of the spring 30, the second piezoelectric ceramic sensor 18 is fixed on the bottom of the magnetic table base adsorption device 19, and the two piezoelectric ceramic sensors are respectively used as a driver and a receiver, and the impedan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com