Planet gear

A planetary gear and gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of weak bending resistance and impact resistance of planetary gears, undercutting phenomenon of planetary gears, and service life. Short and other problems, to achieve the effects of good mechanical strength, extended service life, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

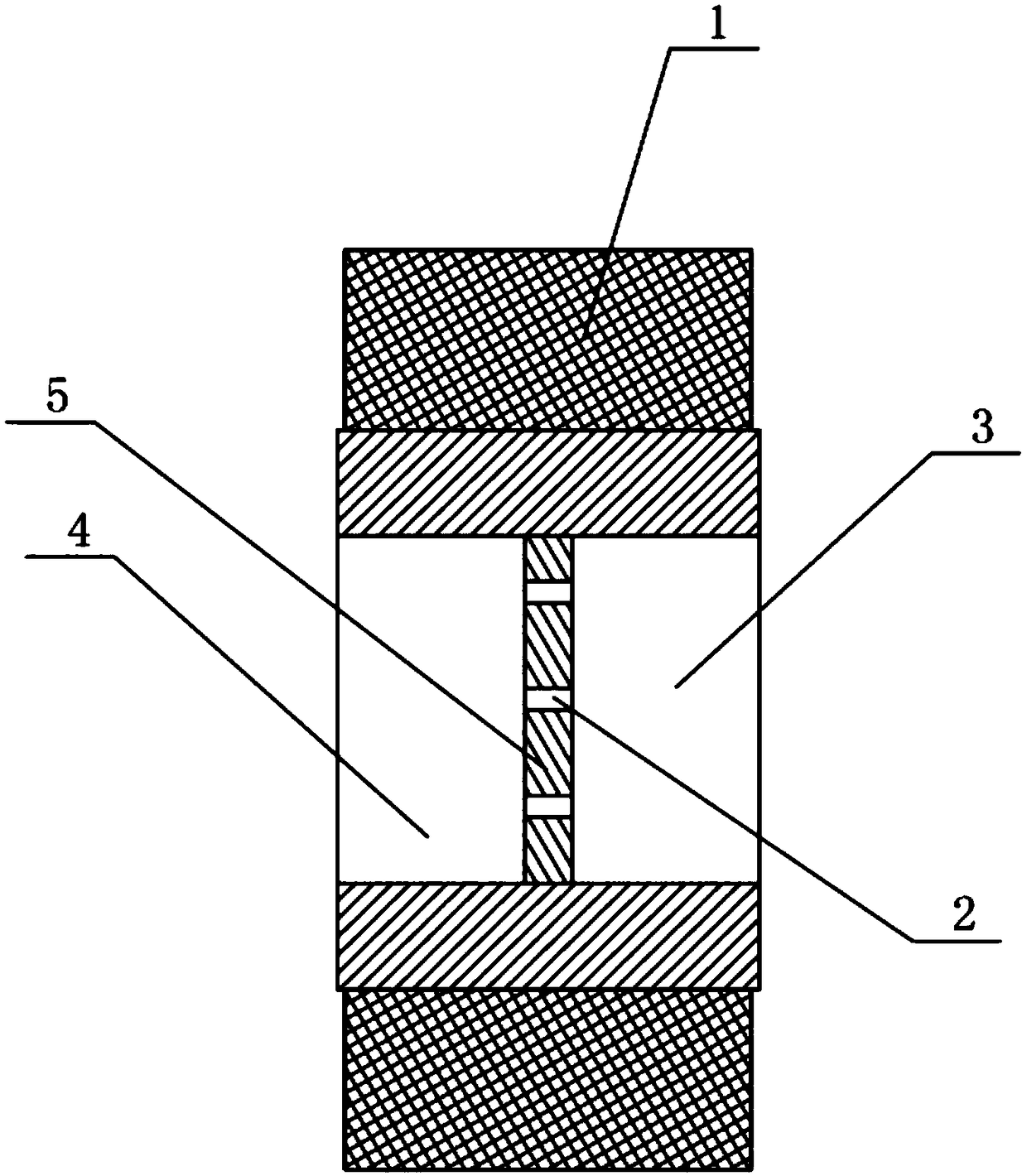

[0019] like figure 1 Said, a planetary gear, comprising a gear body 1, said gear body 1 has a rim, said gear body is provided with a gear on the outer surface of the rim, and the pressure angle of the gear is 25-27°. The center of the rim of the gear body 1 is provided with a left end inner hole 4 and a right end inner hole 3 , and a retaining ring 5 is arranged between the left end inner hole 4 and the right end inner hole 3 .

[0020] In this embodiment, the diameter of the inner hole 4 at the left end is the same as that of the inner hole 3 at the right end. The retaining ring 5 is provided with retaining ring holes 2 evenly distributed, and at the same time, the diameter of the retaining ring holes 2 is smaller than the diameters of the inner hole 4 at the left end and the inner hole 3 at the right end.

[0021] In addition, considering the actual use effect, the retaining ring 5 is made of stainless steel and has a thickness of 1-2 cm. The gear body 1 is a ring-shaped g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com