Design method of magnetic type planet gear

A design method and planetary gear transmission technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve problems such as damage to transmission, plastic deformation of gear tooth profile shape, gear tooth breakage, etc., to eliminate noise and vibration, increase torque density, increase the effect of transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to clearly illustrate the technical features of the present solution, the present invention will be described in detail below through specific implementation methods and in conjunction with the accompanying drawings.

[0043] It should be noted that components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and techniques are omitted herein to avoid unnecessarily limiting the present invention.

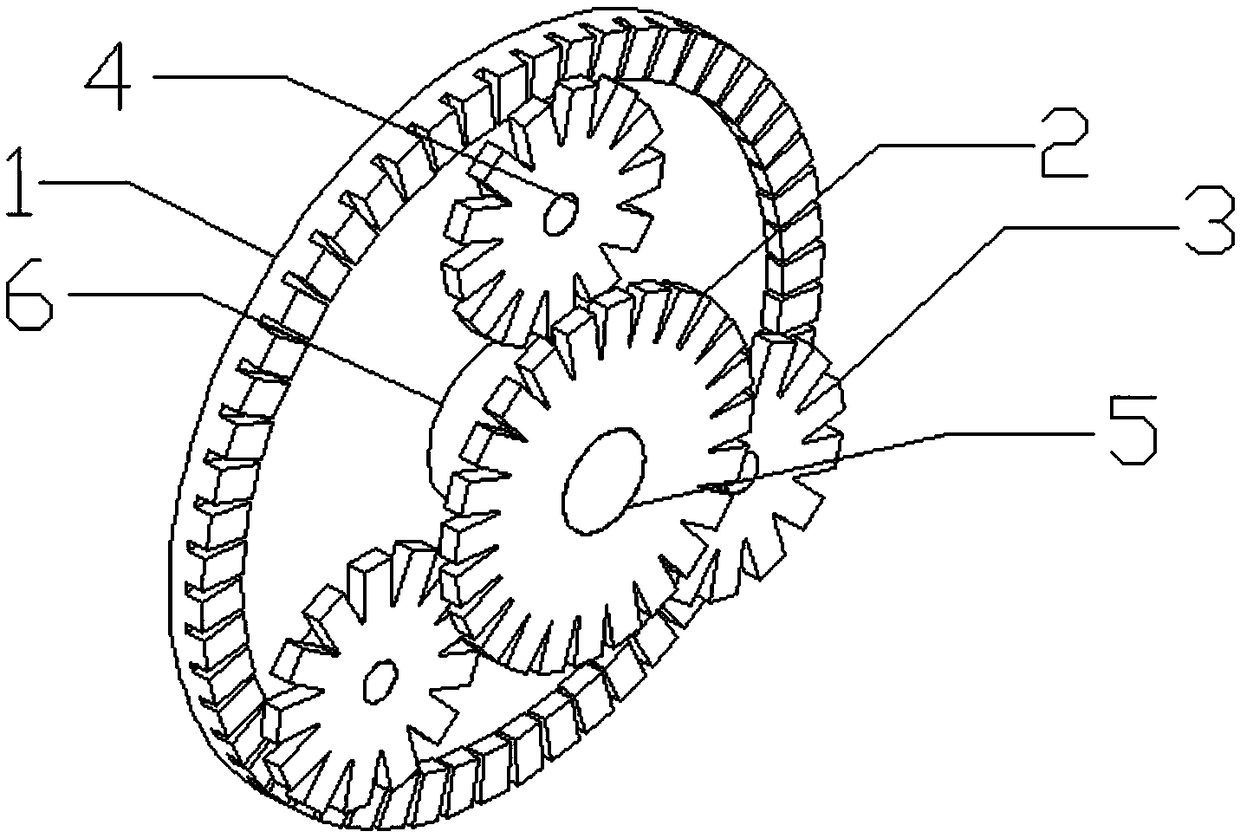

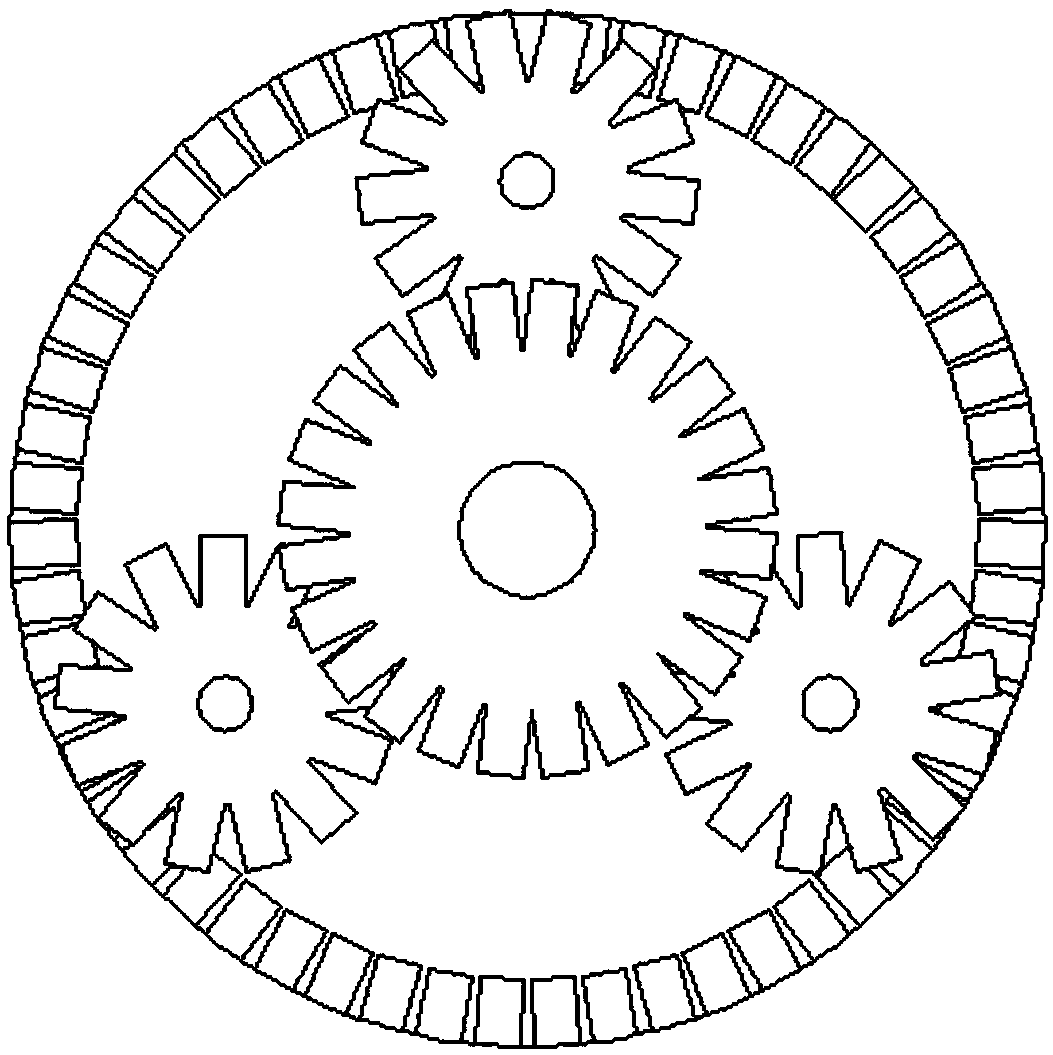

[0044] Such as Figure 1-3 As shown, a design method of a magnetic planetary gear, the design includes a magnetic sun gear 1, a magnetic center gear 2, and a magnetic planetary gear 3; the magnetic sun gear 1 and the magnetic planetary gear 3 are axially magnetically coupled, and the magnetic The planetary wheel 3 and the magnetic center wheel 2 are axially magnetically coupled, and the magnetic poles of the magnetic gear blocks on the axial coupling surface of the magnetic center wheel are distributed in N, S, N, S, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com