Hydraulic axial plunger type transmission roller with reverse stop and speed-regulating functions

A technology of drive rollers and axial columns, which is applied in the field of hydraulic axial plunger drive rollers and drive rollers for belt conveyors, can solve the problems of increased production costs, complicated installation and commissioning, and increased maintenance costs of supporting facilities. Reduce production costs and facilitate installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

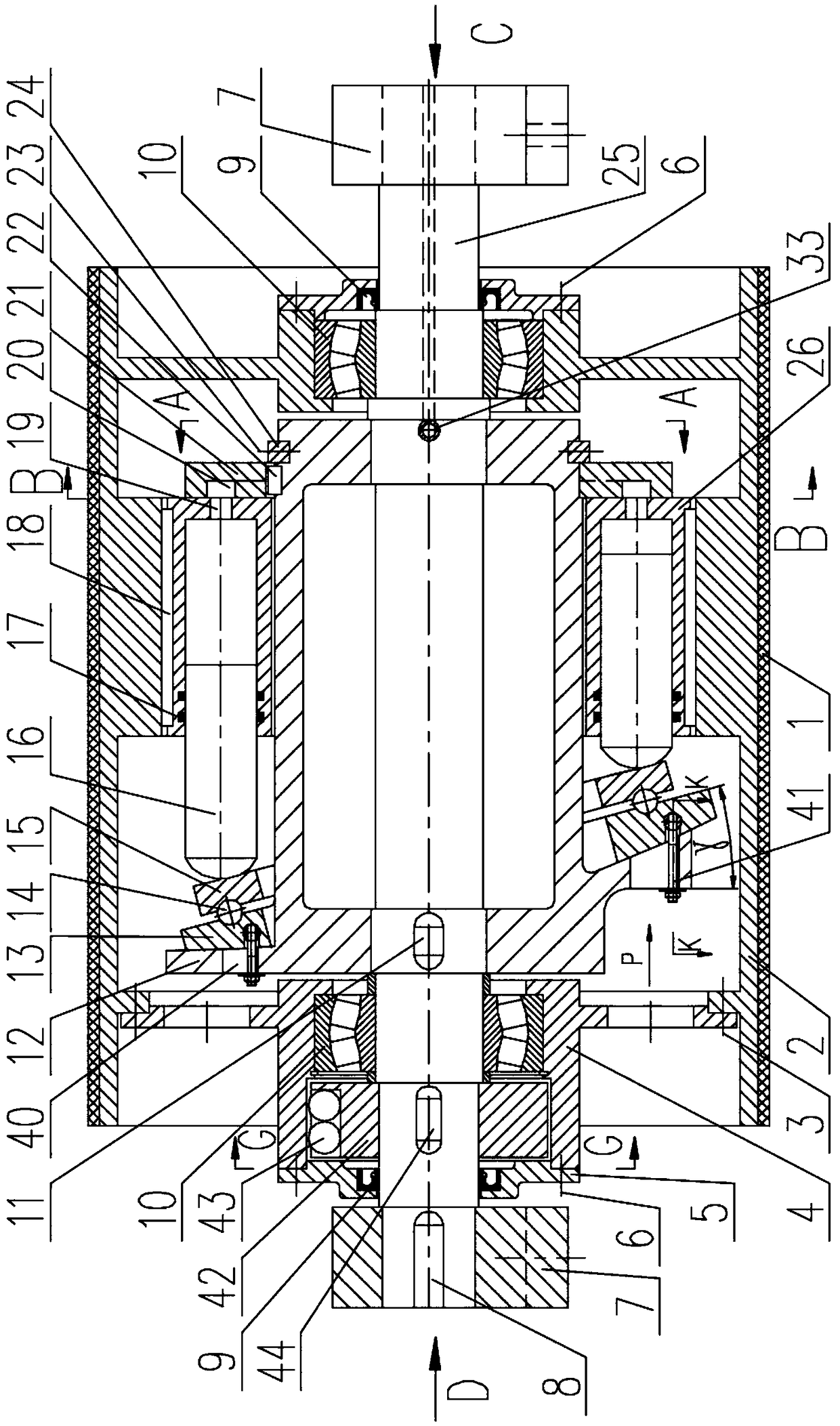

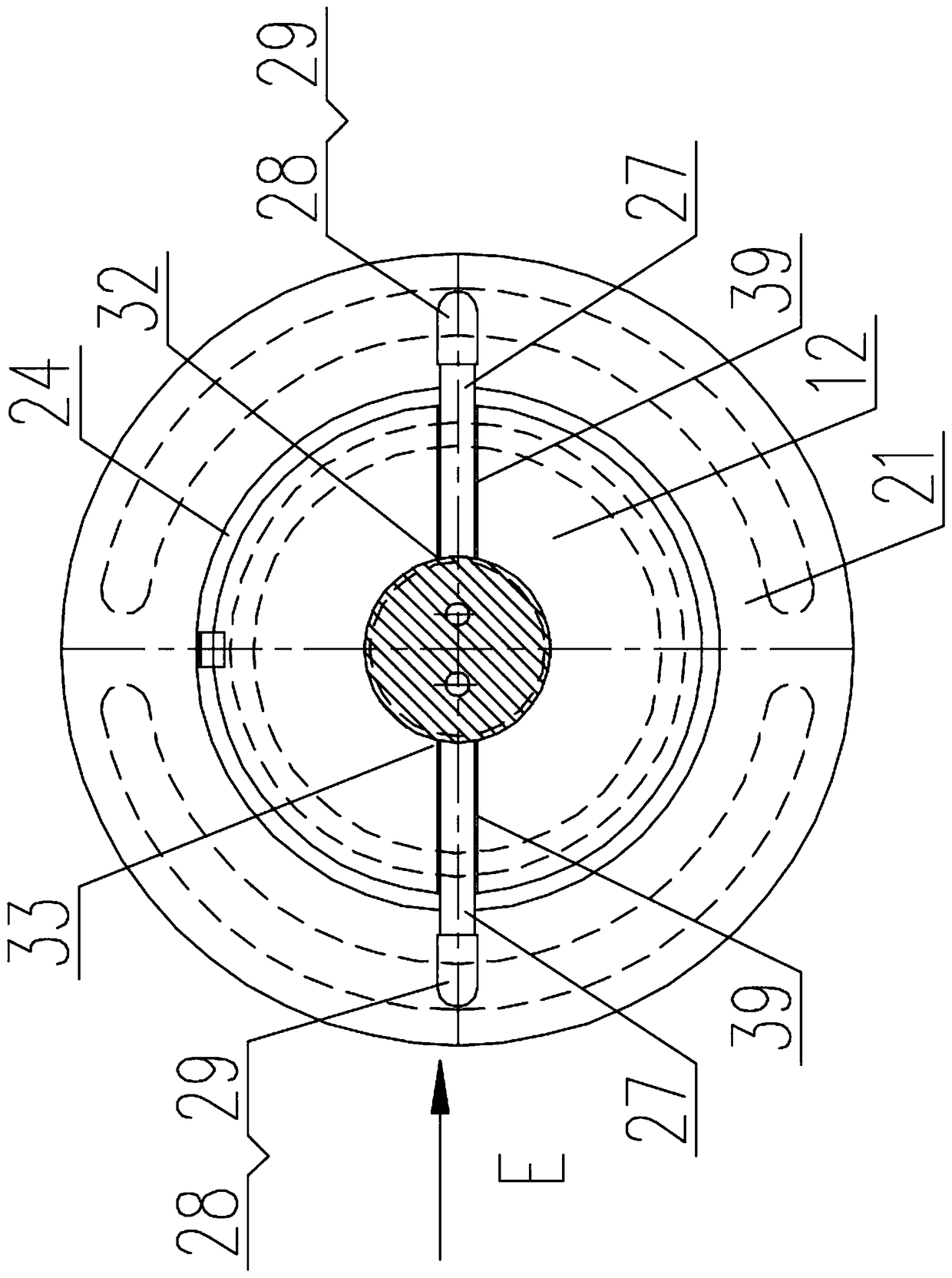

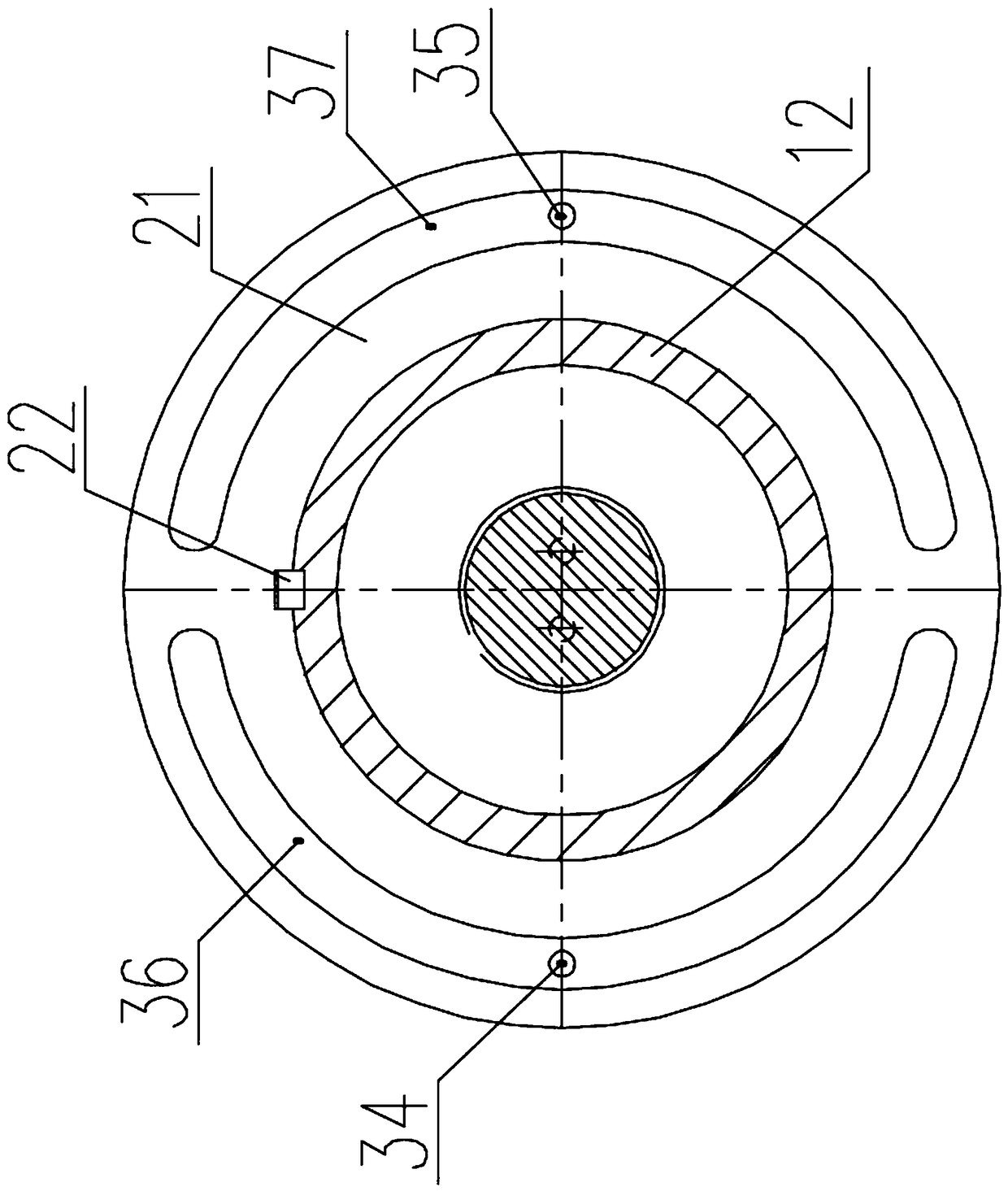

[0035] Below in conjunction with accompanying drawing, the present invention will be further described (hereinafter referred to as figure 1 The direction to the right of the front is described as the front).

[0036] Such as figure 1 As shown, the hydraulic axial plunger transmission drum with backstop and speed regulating functions includes a cylinder body 2, a spoke plate 4, and a roller shaft 25; the outer surface of the cylinder body 2 is covered with a rubber layer 1, and two spoke plates 4 The front and back are symmetrically fixed inside the cylinder body 2, and at least one web plate 4 is fixedly installed inside the cylinder body 2 through the web plate mounting bolts 3. The center position of the web plate 4 is provided with a bearing seat structure, and the interior of the bearing seat structure is provided with The bearing 10 is provided with a bearing end cover 5 on the outside, and a dust-proof seal 9 is provided inside the bearing end cover 5. The bearing end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com