Finished brick automatic sorting production line

A production line, automatic technology, applied in conveyor objects, coatings, conveyors, etc., can solve the problems of high labor intensity, low work efficiency, complex transfer procedures, etc., and achieve a stable and uniform conveying process, simple structure, and reduced labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

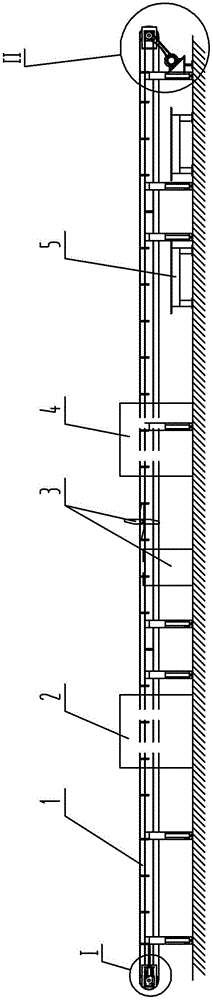

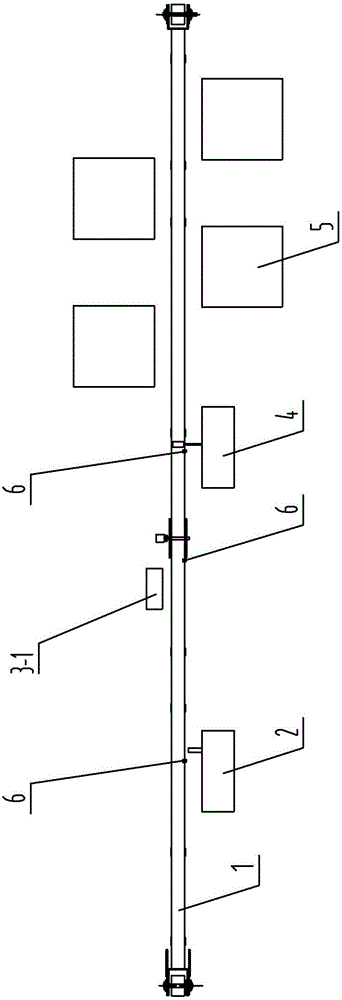

[0027] see Figure 1 to Figure 4 , in the figure, the finished brick automatic sorting production line of the present invention includes a conveying line 1, on which a code spraying mechanism 2, an overturning mechanism 3 and a glue spraying mechanism 4 are sequentially installed on the conveying line and along the conveying direction of the conveying line. The mechanism and the glue spraying mechanism are placed on one side of the conveying line, and there are brick swing platforms 5 on both sides of the rear of the conveying line, and photoelectric switches are installed on the conveying line on the side of the code spraying mechanism, turning mechanism and glue spraying mechanism. 6. The conveying line includes a frame 1-1, and the two ends of the frame are respectively equipped with a driving roller 1-2 and a passive roller 1-3, and the driving roller and the passive roller are connected through a surrounding synchronous belt 1-4, and the driving roller The shaft end sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com