An electronic differential control system

A technology of control system and differential gear, which is applied in the direction of control drive, control device, motor, etc., can solve the problems of not being suitable for the use of electric vehicles, the inability to achieve precise adjustment, and the large loss of mechanical power transmission, etc., to achieve simple structure and anti-interference The effect of strong ability and fast frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

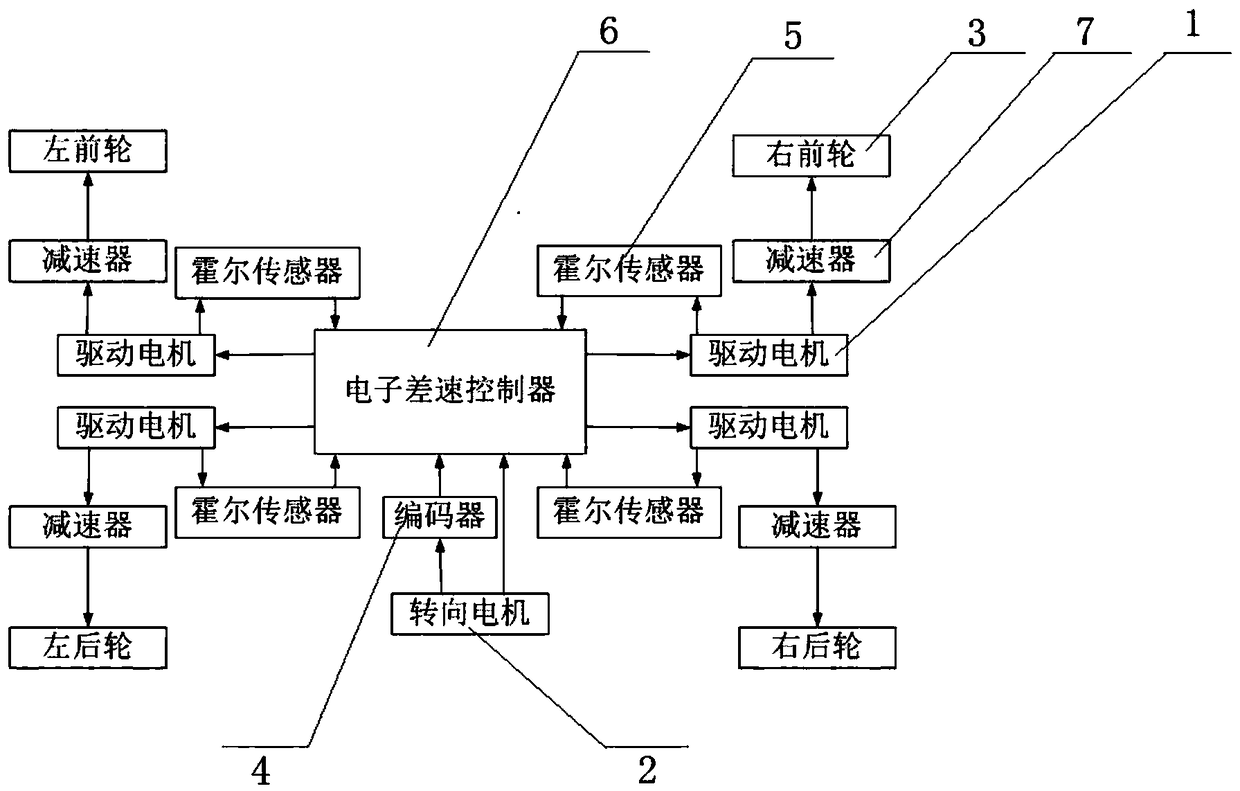

[0021] Such as figure 1 As shown, an electronic differential control system includes a drive motor 1, a steering motor 2, a wheel 3, an encoder 4, a Hall sensor 5, an electronic differential controller 6 and a speed reducer 7, and the drive motor 1 has 4, the wheels 3 have 4, and each of the wheels 3 corresponds to one of the driving motors 1, and each of the driving motors 1 and the wheels 3 is connected with a reducer 7, 4 The drive motor 1 drives the corresponding wheels 3 to provide forward power; the steering motor 2 provides steering power for the wheels 3; the encoder 4 calculates the number of output pulses of the photoelectric encoder per second. The number can reflect the current speed of the drive motor 1, which is used to provide two pulse signals with a phase difference of 90 degrees when judging the direction of rotation, and cooperates with the steering motor 2 to control the steering; the Hall sensor 5 is used for accurate The rotational speeds of the four dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com