Five-layered corrugated paper production line

A production line and corrugated paper technology, applied in the field of corrugated paper production, can solve the problems affecting the production process of corrugated paperboard, reduce wood usage, and low production efficiency, and achieve the effects of reducing manual selection time, reducing waste rate, and slowing down the conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

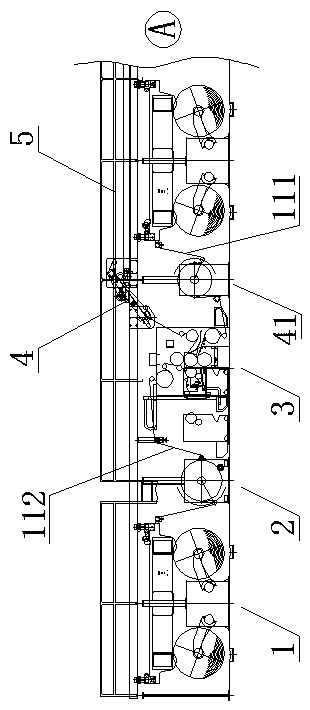

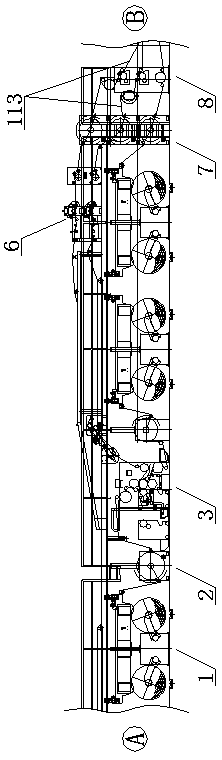

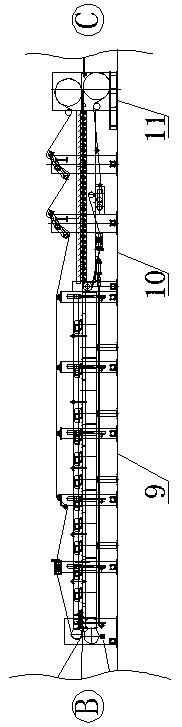

[0027] A five-layer corrugated paper production line of the present invention will be further described with reference to the accompanying drawings.

[0028]A five-layer corrugated paper production line, including a plurality of base paper racks 1 for unwinding base paper, a face paper preheating wheel 2 and a core paper preheating wheel 41 arranged between the two base paper racks 1, for rolling the core paper 112 The single corrugated paper machine 3 which is formed and combined with the surface paper 111 to form a single corrugated cardboard 113, the uplifting device 4 and the two-layer paper frame 5 arranged above the single corrugated cardboard 3, the conveying device 6 for conveying the single corrugated cardboard 113, Triple preheating wheel 7 for preheating single corrugated cardboard 113 and face paper 111, pasting machine 8 for pasting face paper 111 and two layers of single corrugated cardboard 113, used for pasting face paper 111 and two layers A cardboard forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com