Cooling and dehydrating device for reducing internal stress of plastic particles and production technology

A dehydration device and a technology of plastic granules, which are applied in the field of plastic processing, can solve the problems of uncontinuous operation of the production process, increased labor intensity of operators, and insufficient dehydration in the dehydration tank, so as to save manpower, reduce orientation stress, and reduce molecular stress. small effect of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

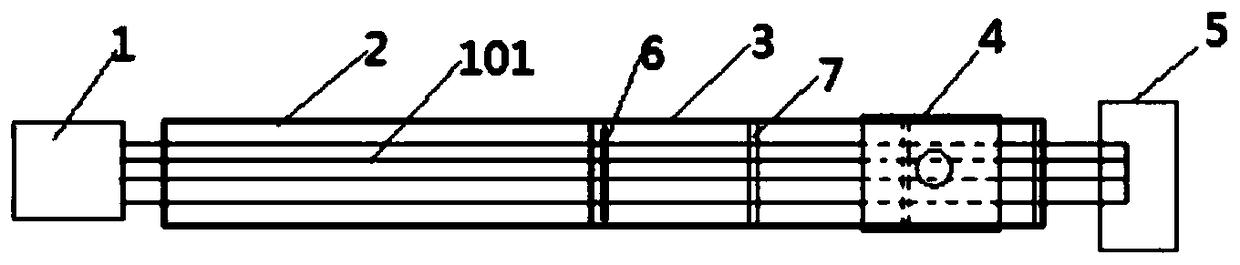

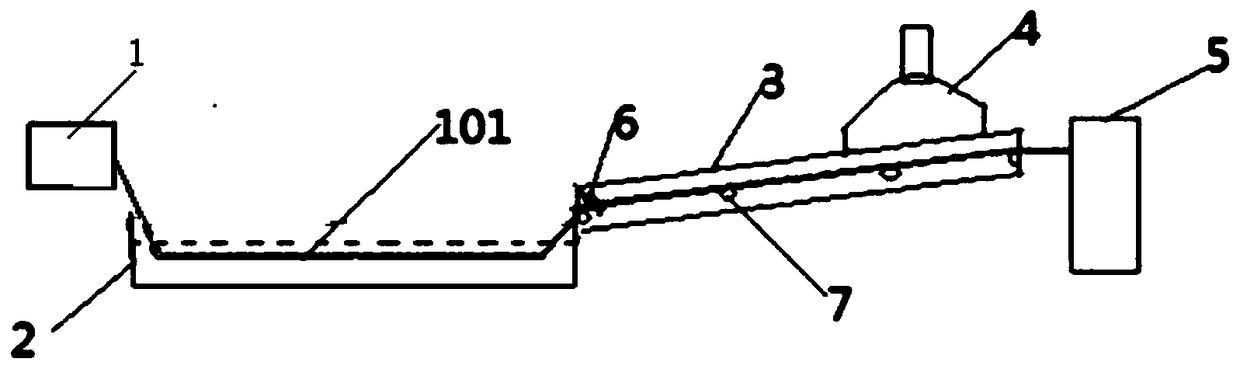

[0030] A cooling and dehydration device and production process for reducing the internal stress of plastic particles, the cooling and dehydration device includes a cooling water tank 2, a dehydration tank 3 and a hot air box 4, one end of the cooling water tank 2 is close to the barrel head 1, and the cooling water tank 2 The other end is fixedly connected to the dehydration tank 3 which is arranged obliquely. A movable water baffle 6 is arranged at the connection end between the dehydration tank 3 and the cooling water tank 2. A hot blow box 4 is arranged on the upper part of the dehydration tank 3. A plurality of rollers 7 are arranged inside the dehydration tank 3. A granulator 5 is arranged on the outside of the dehydration tank 3 away from the cooling water tank 2, and the plastic filament 101 is extruded from the barrel head 1, and reaches the inside of the granulator 5 through the cooling water tank 2, the dehydration tank 3 and the hot blow box 4. .

[0031] Wherein, t...

Embodiment 2

[0039] A cooling and dehydration device and production process for reducing the internal stress of plastic particles, the cooling and dehydration device includes a cooling water tank 2, a dehydration tank 3 and a hot air box 4, one end of the cooling water tank 2 is close to the barrel head 1, and the cooling water tank 2 The other end is fixedly connected to the dehydration tank 3 which is arranged obliquely. A movable water baffle 6 is arranged at the connection end between the dehydration tank 3 and the cooling water tank 2. A hot blow box 4 is arranged on the upper part of the dehydration tank 3. A plurality of rollers 7 are arranged inside the dehydration tank 3. A granulator 5 is arranged on the outside of the dehydration tank 3 away from the cooling water tank 2, and the plastic filament 101 is extruded from the barrel head 1, and reaches the inside of the granulator 5 through the cooling water tank 2, the dehydration tank 3 and the hot blow box 4. .

[0040] Wherein, t...

Embodiment 3

[0048] A cooling and dehydration device and production process for reducing the internal stress of plastic particles, the cooling and dehydration device includes a cooling water tank 2, a dehydration tank 3 and a hot air box 4, one end of the cooling water tank 2 is close to the barrel head 1, and the cooling water tank 2 The other end is fixedly connected to the dehydration tank 3 which is arranged obliquely. A movable water baffle 6 is arranged at the connection end between the dehydration tank 3 and the cooling water tank 2. A hot blow box 4 is arranged on the upper part of the dehydration tank 3. A plurality of rollers 7 are arranged inside the dehydration tank 3. A granulator 5 is arranged on the outside of the dehydration tank 3 away from the cooling water tank 2, and the plastic filament 101 is extruded from the barrel head 1, and reaches the inside of the granulator 5 through the cooling water tank 2, the dehydration tank 3 and the hot blow box 4. .

[0049] Wherein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com