A production jig for an automobile engine balance shaft

A technology of automobile engine and balance shaft, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc. It can solve the problems of difficult guarantee of coaxiality, difficult clamping of chucks, and reduced production efficiency, so as to avoid inconsistent positioning references , Improve production efficiency, improve the effect of production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

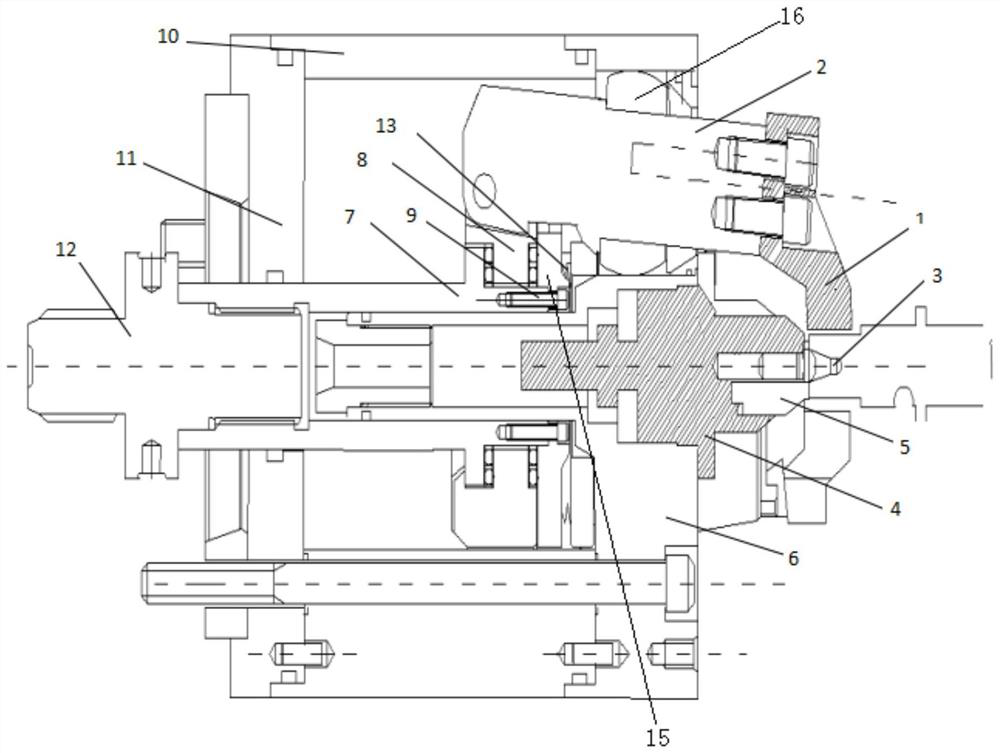

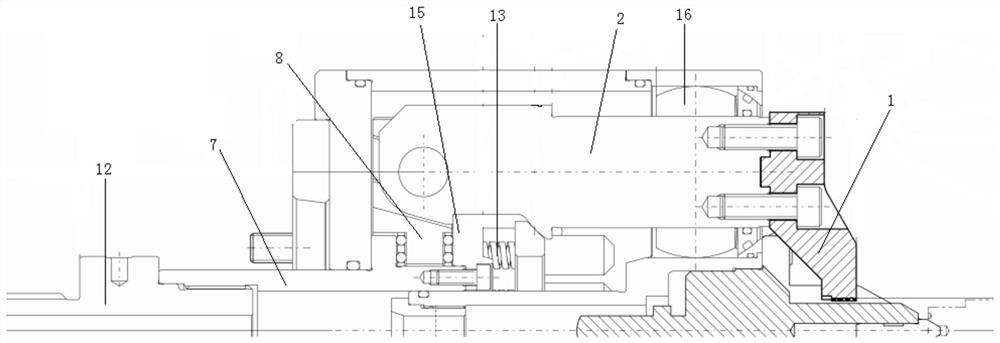

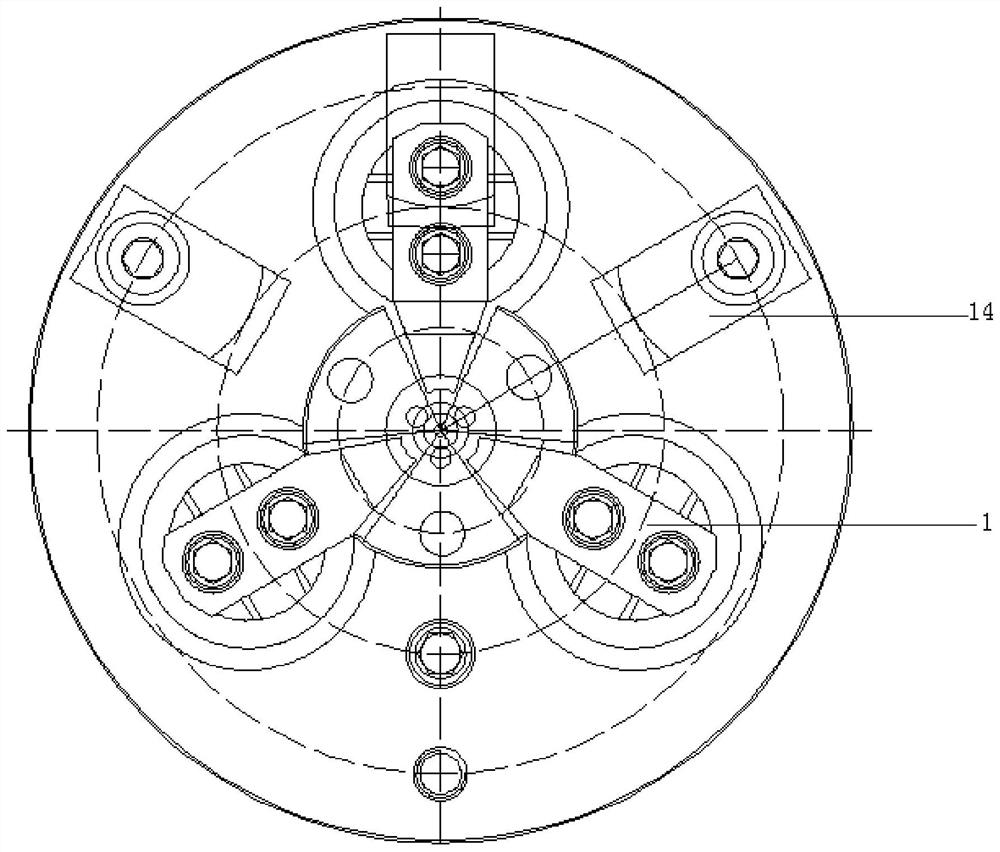

[0025] refer to Figure 1-3 , a kind of fixture for automobile engine balance shaft production, used for clamping and fixing during the processing and production of automobile engine balance shaft, comprising a clamp body 10, which is installed on a machine tool through a transition plate 11, and one end of the clamp body 10 is fixedly installed with a chuck 6, and the chuck The end drive 4 is fixedly installed on the disc 6, and the top 3 for centering the center hole of the balance shaft 17 is fixedly installed on the end drive 4. The top 3 is fixed by a tappet 5, and a plurality of pairs of balance shafts 17 are arranged on the outside of the chuck 6. The periphery carries out fixed retractable jaw 1.

[0026] Three grooves are evenly opened along the circumference on the end face drive 4, and three sliders 2 are uniformly arranged at the front end of the chuck in the chuck 6, and the telescopic jaws 1 are fixedly installed on the sliders 2, so that the three telescopic jaw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com