Groove-type cable bridge frame horizontal bend manufacturing method

A technology of cable bridge and manufacturing method, which is applied in the direction of cable installation, cable installation device, electrical components, etc., and can solve the problems of slowing down the construction period of horizontal elbows, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

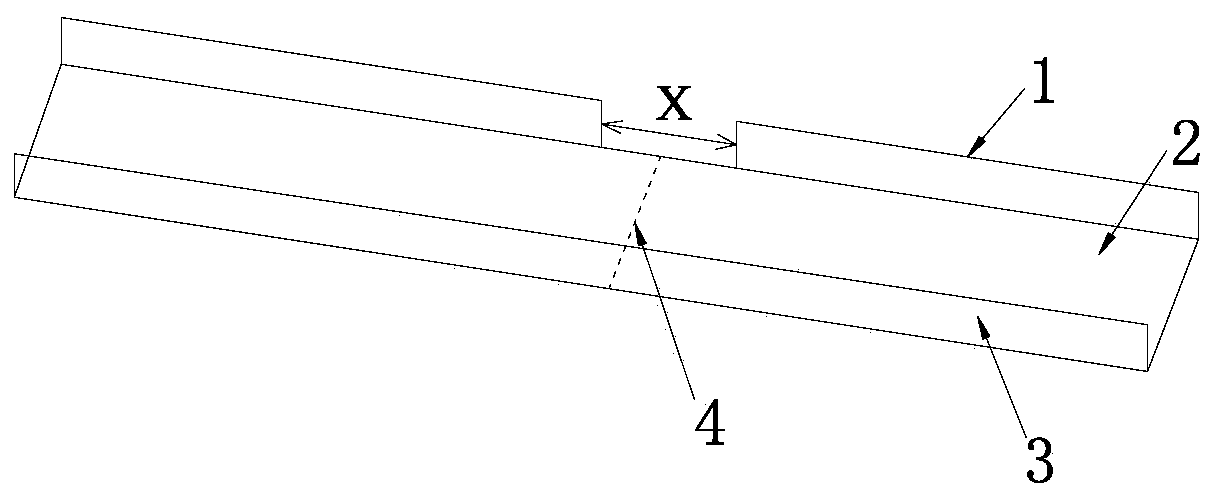

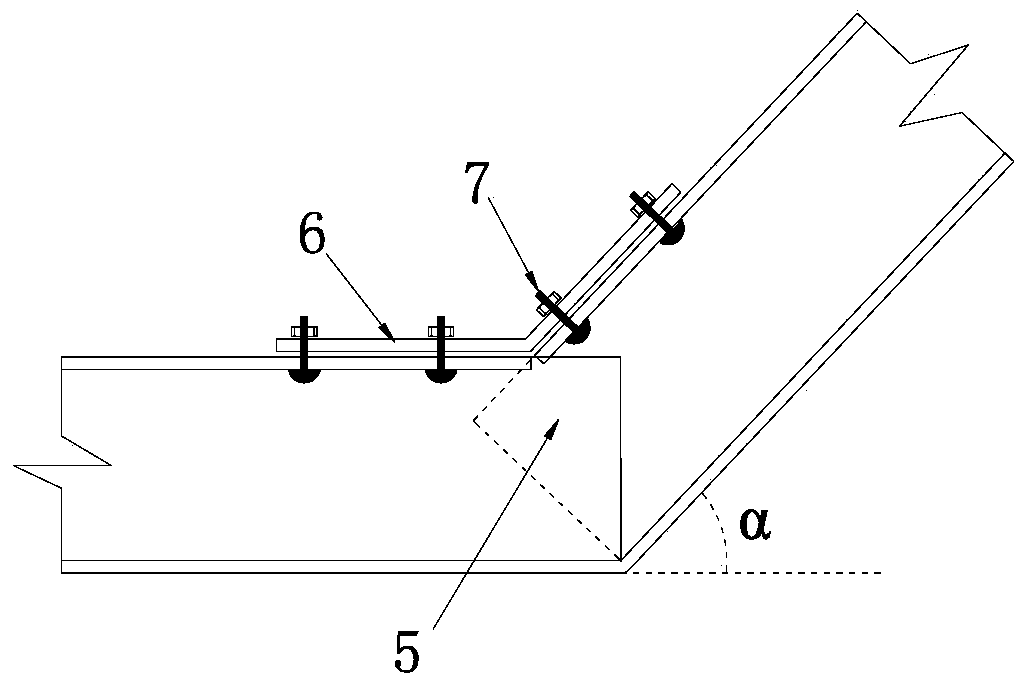

[0021] Below the present invention is further described: as Figure 1-3 As shown, a method for manufacturing a horizontal elbow of a trough-type cable tray is carried out according to the following steps:

[0022] First, measure the two bridges that need to be connected by an elbow to determine the prefabricated horizontal elbow angle α.

[0023] Secondly, calculate the side cutting length x of the bridge: x=2b*tgα, where b is the width of the bridge.

[0024] Third, cut the bridge frame: 1) cut and remove the x length on the inner side 1 of the bridge frame; 2) take the x area as the base, and make a vertical line 4 on the bottom surface 2 of the bridge frame; 3) then cut along the drawn line, Only the bottom surface 2 of the bridge frame is cut and the outer edge 3 of the bridge frame is reserved.

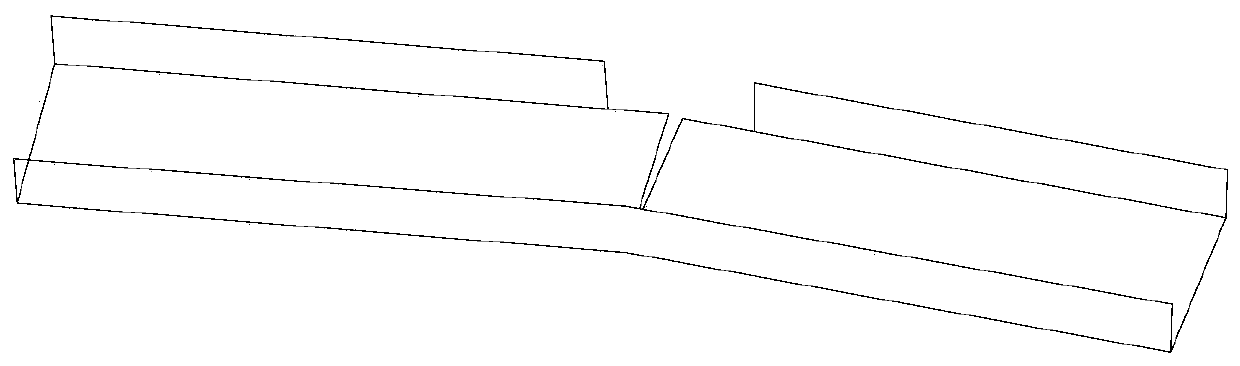

[0025] Fourth, connect and fix: Fold the outer side 3 of the bridge frame in half at the vertex of the vertical line 4, so that the bottom surfaces on both sides of the cut sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com