Building material recycling and smashing device

A crushing device and technology for building materials, applied in the field of construction, can solve problems such as unfavorable later utilization, material jamming, and increased reuse costs, and achieve the effects of facilitating recycling, reducing operating failures, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

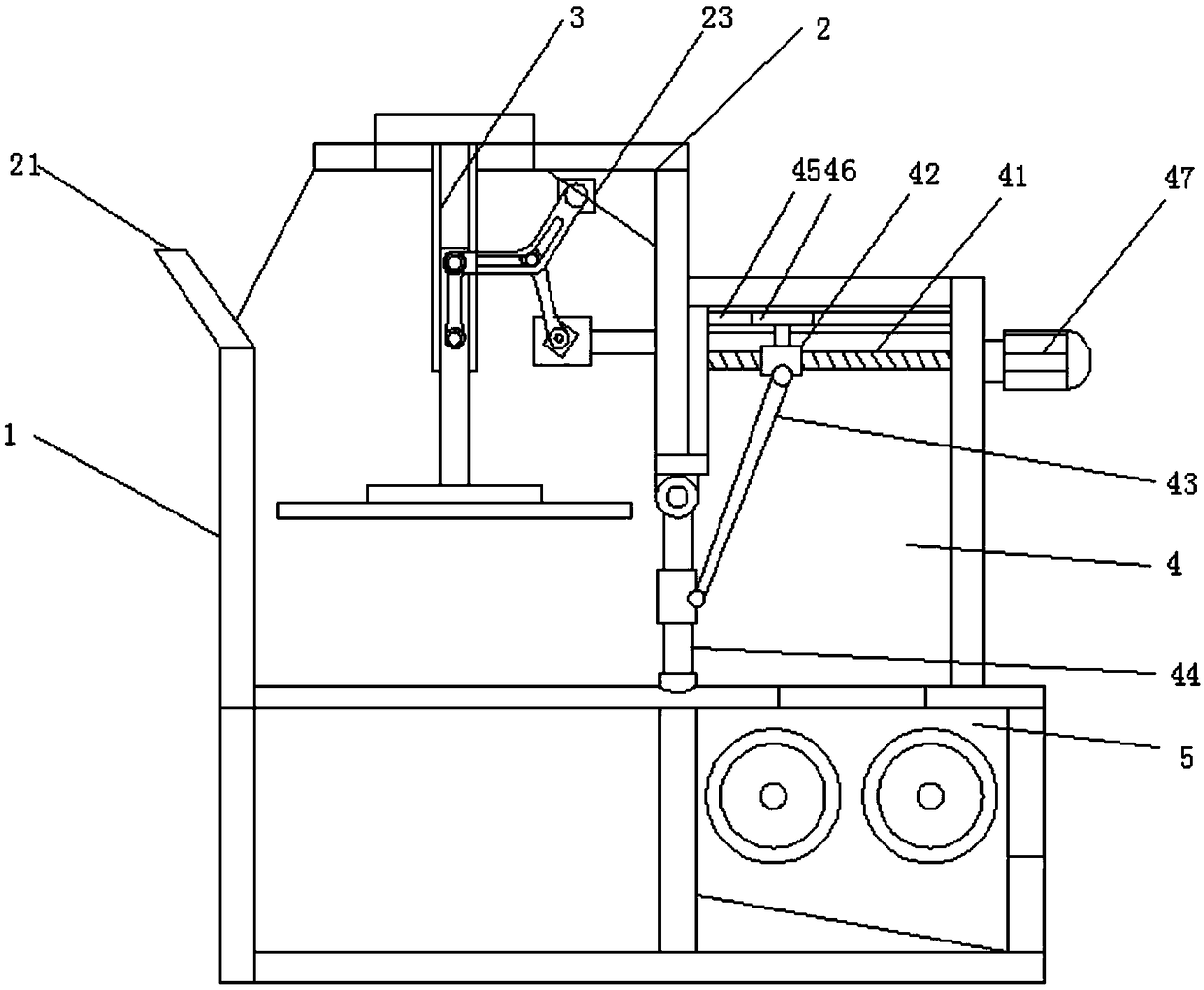

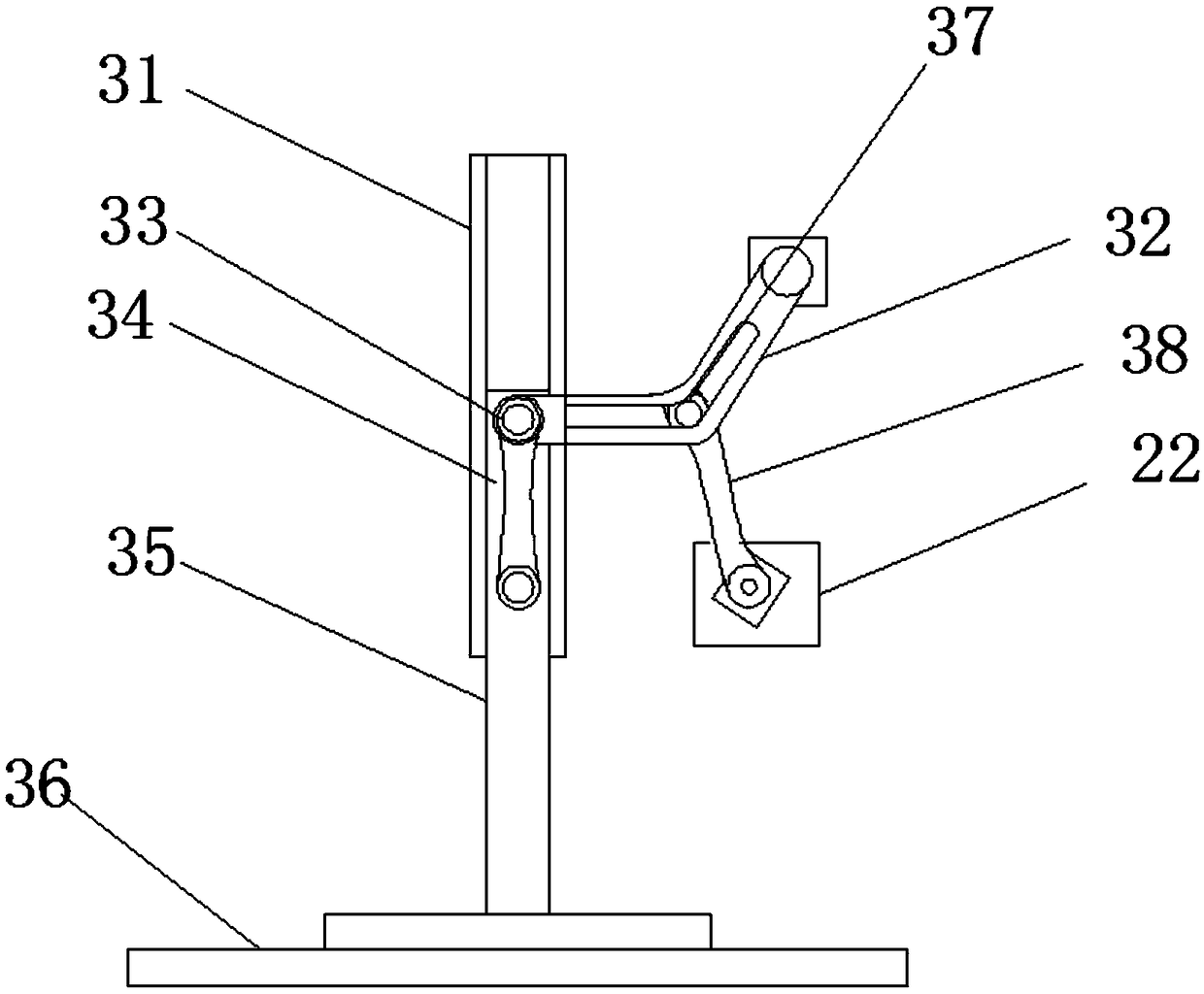

[0023] see figure 1 with figure 2 , a kind of building material recycling and crushing device, comprising a frame 1, the frame 1 is provided with an extrusion chamber 2, and a transmission frame 3 is installed in the extrusion chamber 2, and the transmission frame 3 includes a limit guide rail 31 and transmission guide rail 32, the limit guide rail 31 is installed on the top plate of the extrusion chamber 2, the fixed plate 23 is installed at the oblique position of the extrusion chamber 2, and the transmission guide rail 32 is installed on the erection plate through the movable shaft 23, a transmission block 33 is installed in the limit guide rail 31, a straight rod 35 is installed at the bottom end of the transmission block 33, an extrusion plate 36 is installed at the bottom end of the straight rod 35, and the extrusion chamber 2 A transmission plate 22 is installed on the side wall of the transmission plate 22, a first transmission rod 38 is installed on the top of the f...

Embodiment 2

[0026] As a further optimization of Embodiment 1, on the basis of it, a material delivery chamber 4 is also provided. The material delivery chamber 4 is located on the rear side of the extrusion chamber 2. It is connected with a feeding plate 44, and the feeding plate 44 is installed on the partition between the feeding chamber 4 and the extrusion chamber 2 through a movable shaft, and the top of the feeding chamber 4 is horizontally installed with a threaded rod 41 , the threaded rod 41 is installed with a drive sleeve 42 , and the connecting seat is installed on the surface of the feeding plate 44 , and the drive sleeve 42 and the connecting seat are connected through a tie rod 43 . A feeding motor 47 is installed on the rear side wall of the feeding chamber 4, and the threaded rod 41 is connected with the motor shaft of the feeding motor 47 through a coupling.

[0027] During operation, the feeding motor 47 drives the threaded rod 41 to rotate, drives the transmission sleev...

Embodiment 3

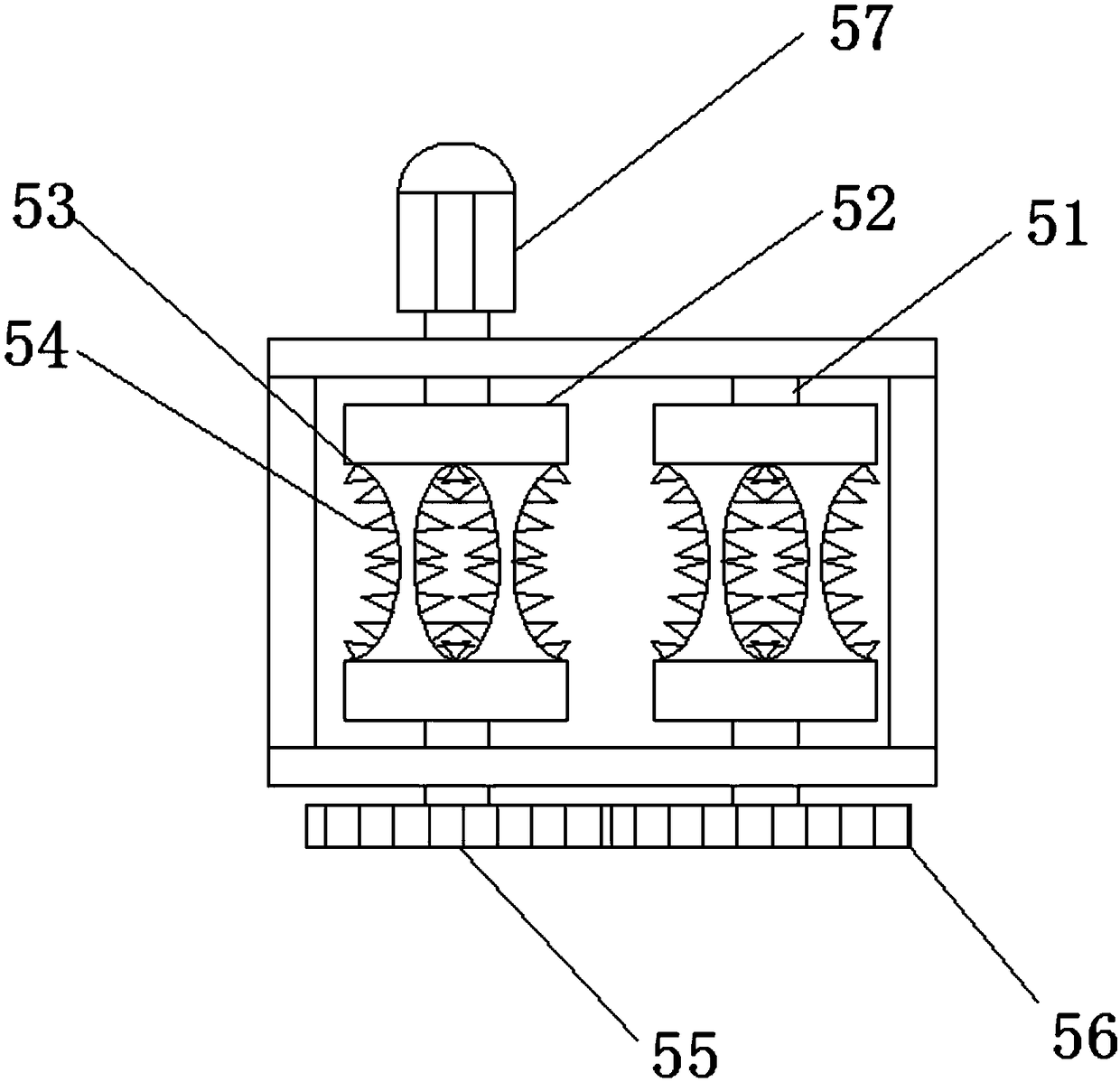

[0030] As a further optimization of the second embodiment, on the basis of it, the bottom end of the feeding chamber 4 is provided with a crushing chamber 5, and two roller shafts 51 are horizontally installed in the crushing chamber 5, and the roller shafts 51 A crushing roller 52 is installed on the top, and several grooves 53 are installed on the crushing roller 52, and crushing teeth 54 are arranged in the grooves 53, and the crushing rollers 52 on the left and right sides are arranged as left and right mirror images. A transmission gear 55 and a driven gear 56 are respectively installed on the front end of the roller shaft 51 , and the transmission gear 55 and the driven gear 56 are gear meshed. A transmission motor 57 is installed on the rear wall of the crushing chamber 5, and the motor shaft of the transmission motor 57 is connected with one of the roller shafts 51 through a coupling.

[0031] During operation, the material falls into the groove 53, and the crushing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com