Acrylic polyurethane synthesis reactor

A technology of acrylic polyurethane and synthetic reactor, which is applied in the direction of polyurea/polyurethane coating, chemical/physical/physicochemical fixed reactor, chemical instrument and method, etc. It can solve problems such as uneven stirring, restriction, and influence on reaction effect , to achieve the effect of improving the effect, improving the synthesis efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

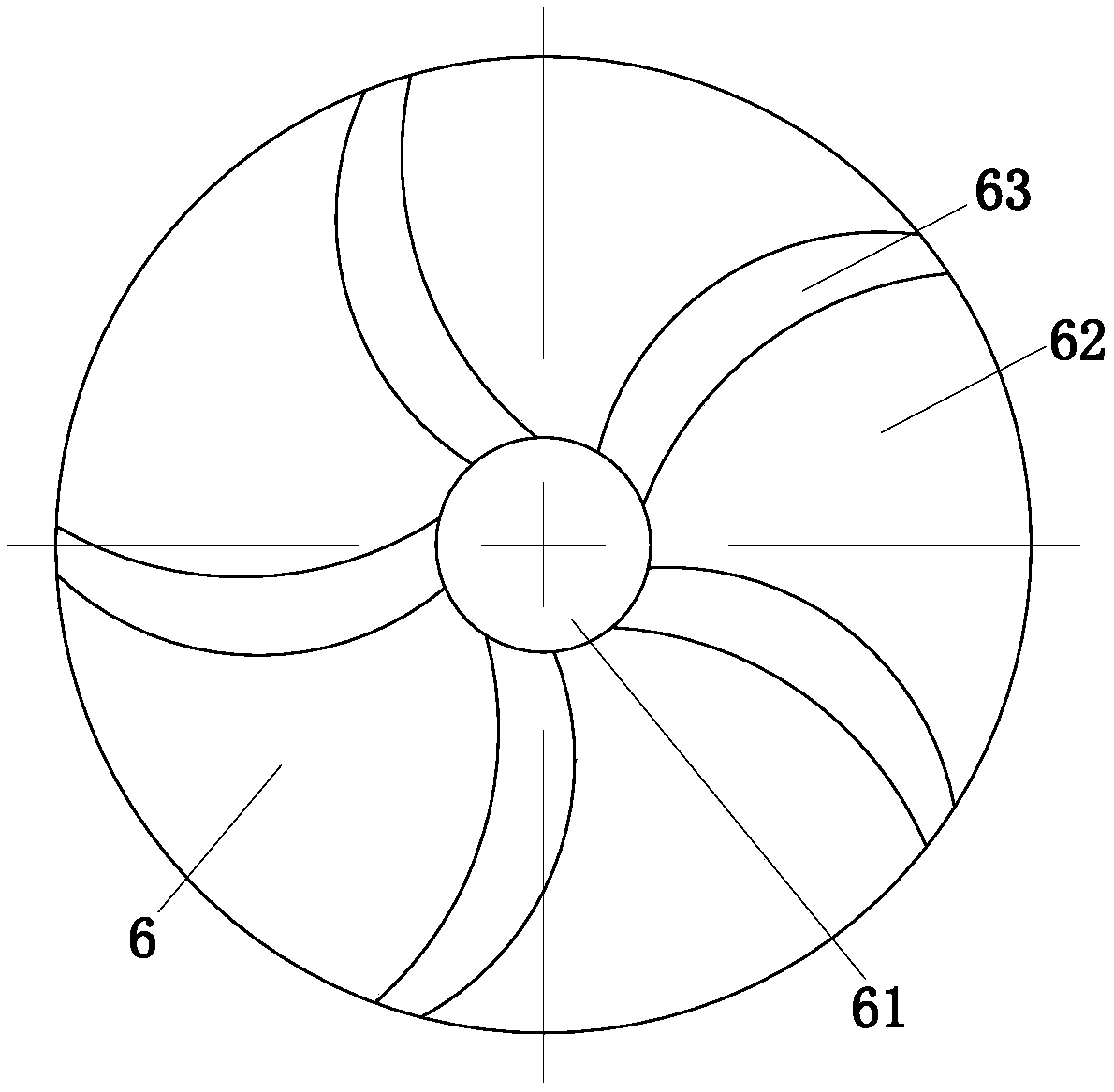

[0037] As an embodiment of the present invention, the No. 2 airbag 42 is provided with a group of No. 2 holes 421, and gas is ejected from the No. 2 holes 421 to accelerate the synthesis of acrylic polyurethane. In the present invention, a group of No. 2 holes 421 are arranged, and the gas is ejected from the No. 2 holes 421. The action of the gas fully stirs the synthesis solution of propylene acid urethane, thereby improving the synthesis efficiency of acrylate urethane.

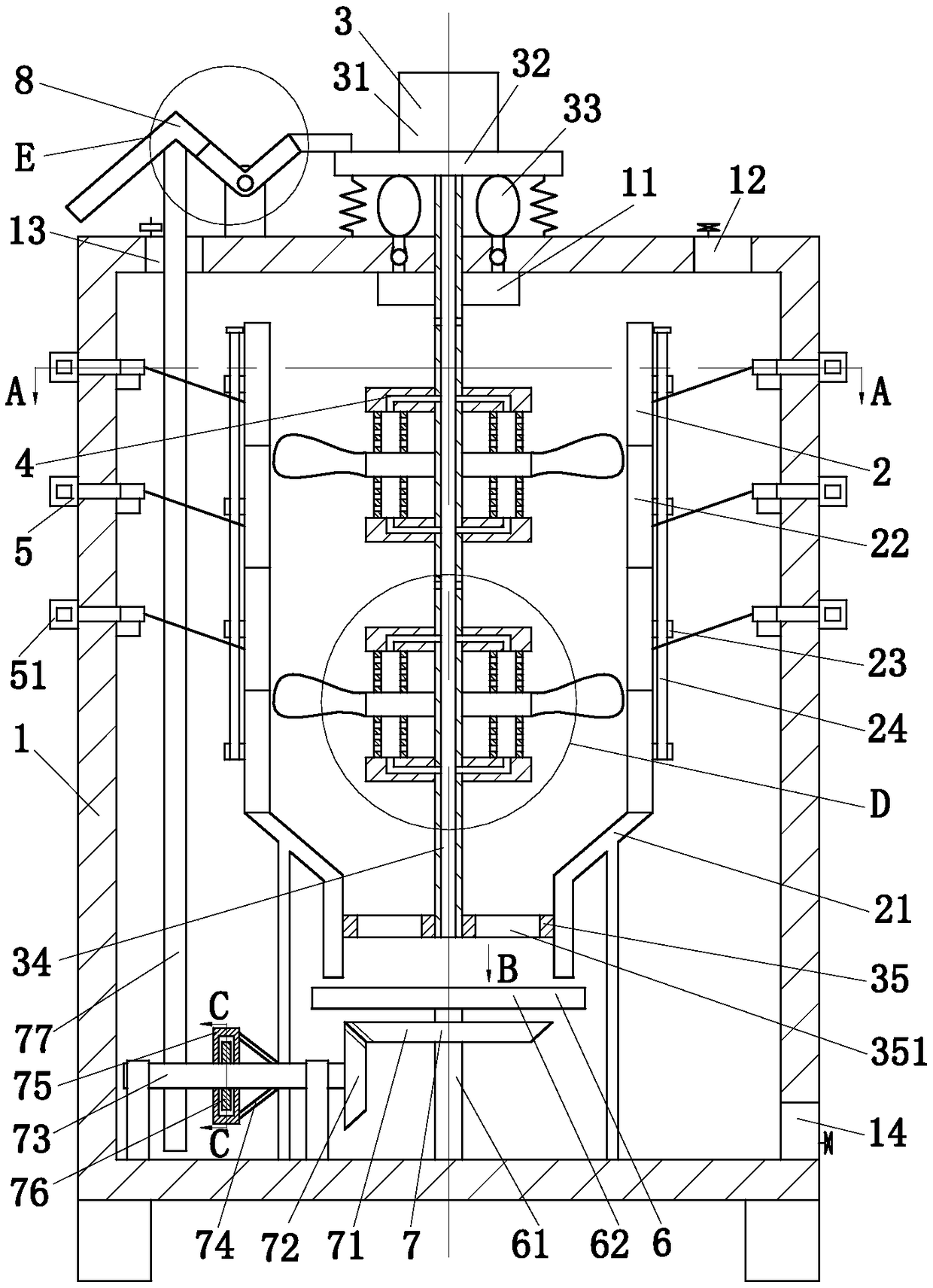

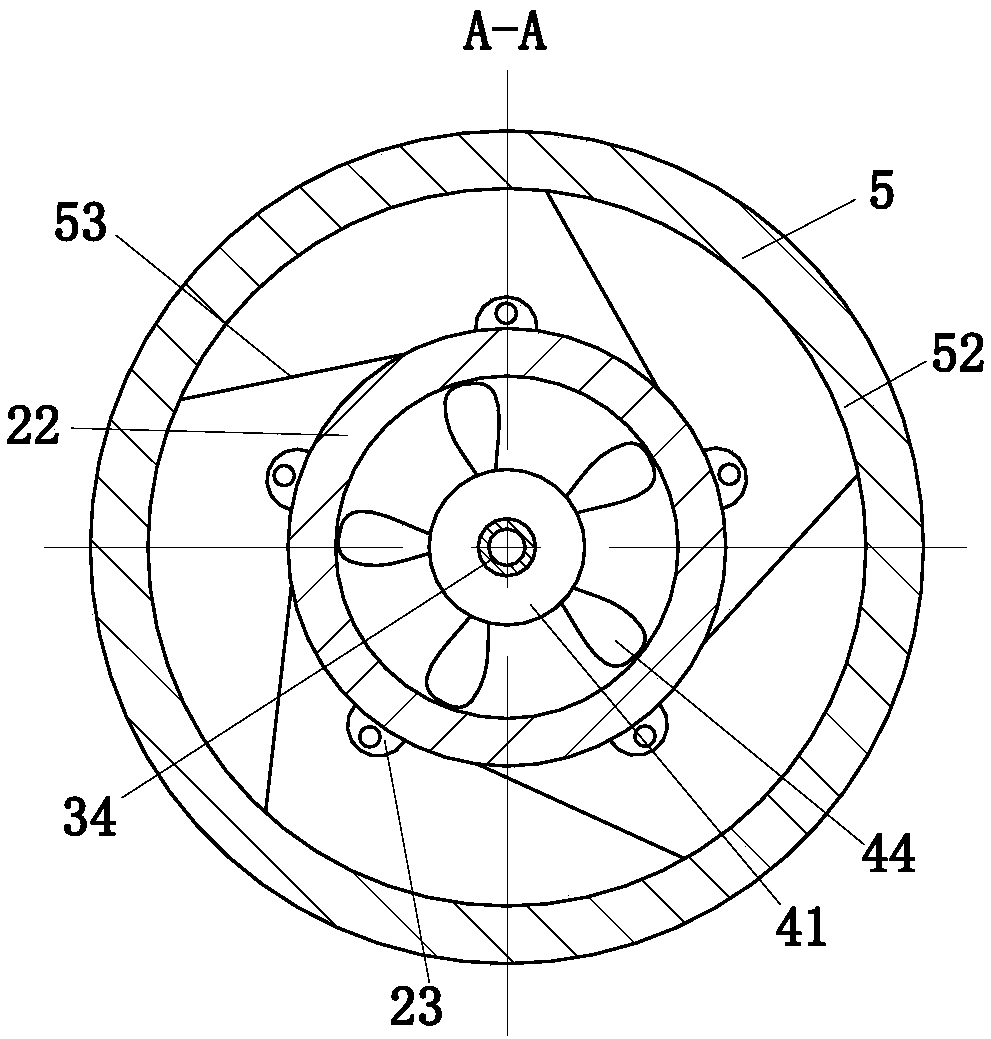

[0038] As an embodiment of the present invention, the second horn body 2 is composed of multiple sets of inner rings 22, and the inner rings 22 at the ends are fixedly installed on the support frame 21; the outer wall of the inner ring 22 is provided with a convex ring 23; The protruding ring 23 is provided with a No. 1 rod 24, which is used to guide the movement of the inner ring 22 in the vertical direction; one end of the No. 1 rod 24 is fixedly installed on the protruding ring of the bottom inner ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com