Sulfur underwater granulation system with reasonable structure

An underwater granulation and sulfur technology, which is applied in the direction of liquid separation into bead droplets, filtration circuits, lighting and heating equipment, etc., can solve the problem that the overall structure of the sulfur underwater granulation system is not scientific and reasonable, economical and practical. Ideal, different sizes of molded pellet products, etc., to avoid liquid sulfur spillover, reduce the probability and cost of daily use, production efficiency and product quality controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

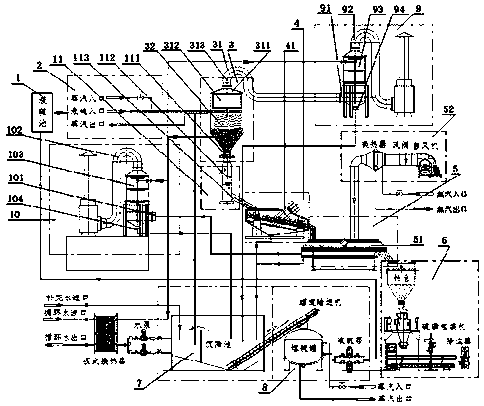

[0024] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

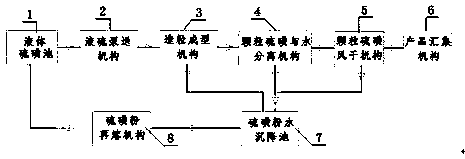

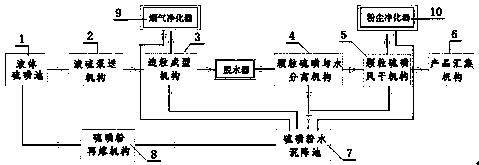

[0025] exist figure 2 and image 3 Among them, the main body of the rationally structured sulfur underwater granulation system of the present invention includes a liquid sulfur pool (referred to as liquid sulfur pool) 1, a liquid sulfur pumping mechanism 2, a liquid sulfur dripping device 31 and a forming water tank 32. Granulation forming mechanism 3. Granular sulfur and water separation mechanism (referred to as solid-liquid separation mechanism) 4. Granular sulfur air-drying mechanism 51. Product collection mechanism 6. The sulfur powder water settling tank 7 and the sulfur powder remelting mechanism 8 are characterized in that they also include a flue gas purifier 9, a dust purifier 10 and a dehydrator 11, wherein:

[0026] The main body of the liquid sulfur dripping device 31 is a closed type with controllable air pressure, including a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com