Novel tea frying machine

A tea frying machine, a new type of technology, applied in the direction of tea treatment before extraction, etc., can solve the problems of uneven heating of tea leaves, insufficient stir-frying of tea leaves, and lower tea quality, so as to avoid uneven heating, avoid damage to tea quality, Even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

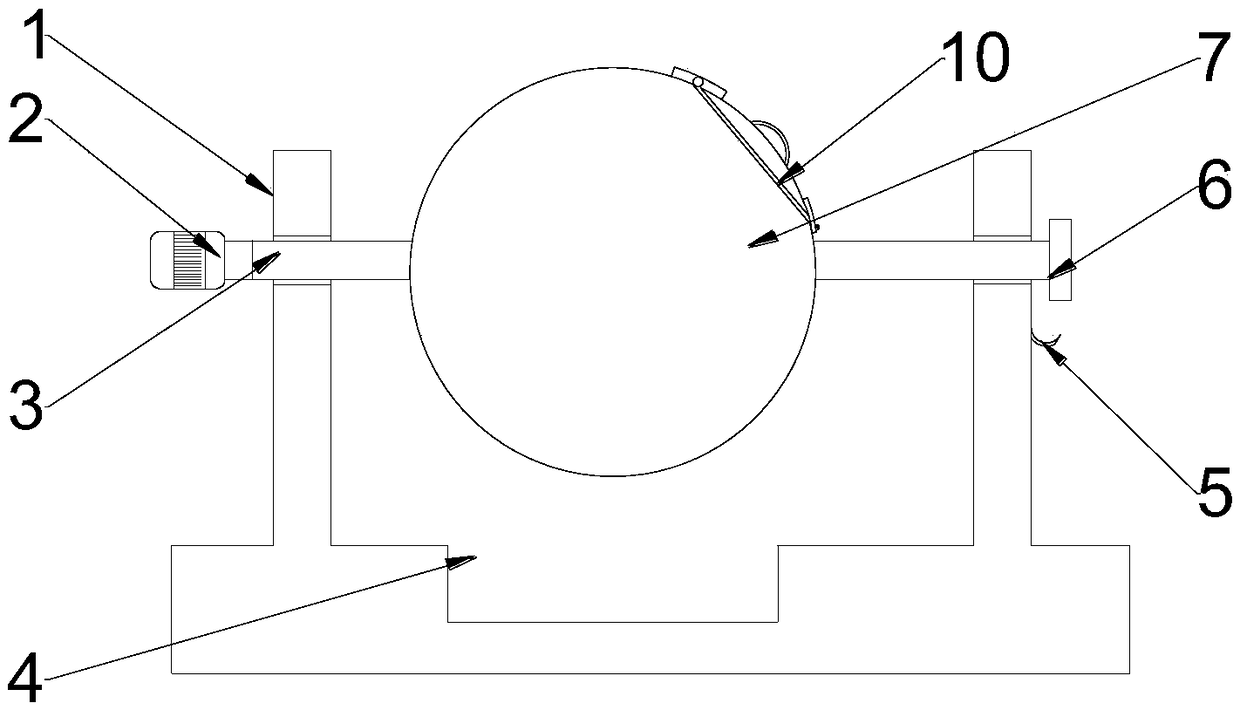

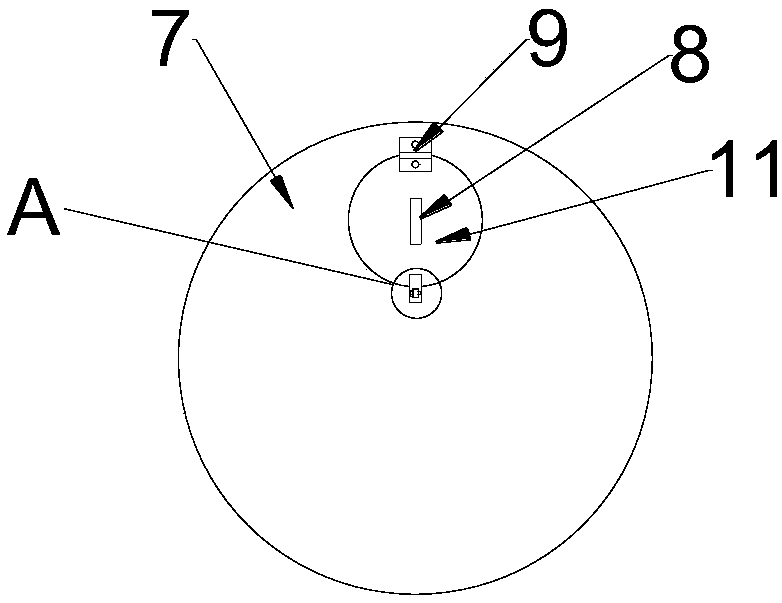

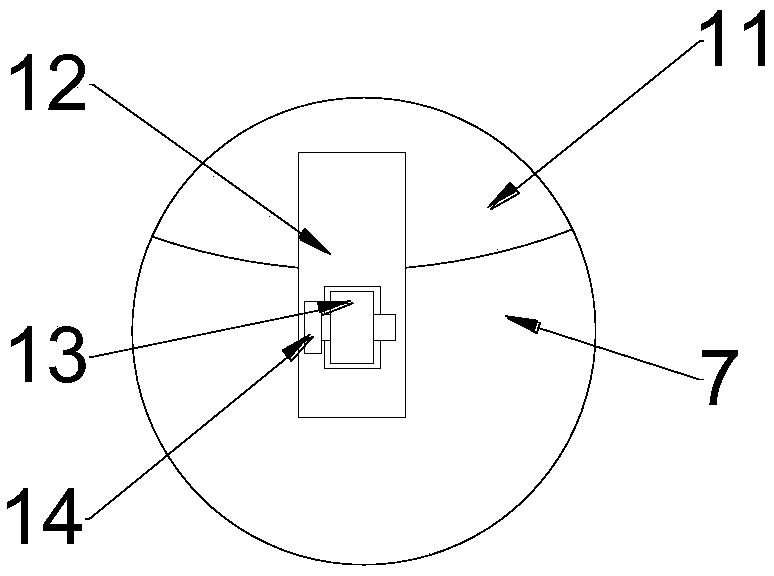

[0026] see Figure 1~3 , a new type of tea frying machine, comprising a frame 1, the frame 1 is provided with a fried tea ball 7, and the outer ball walls on both sides of the middle part of the fried tea ball 7 are provided with a rotating shaft 3 parallel to the frame 1, The rotating shaft 3 runs through both sides of the frame 1; the rotating shaft 3 on one side of the fried tea ball 7 is provided with a motor 2, and the rotating shaft 3 on the other side of the fried tea ball 7 is provided with an anti-off cover 6; the fried tea ball 7 leans against the machine The spherical surface on one side of the frame 1 is provided with a feeding port 10, and the upper part of the feeding port 10 is provided with an arched cover 11 hinged on the tea frying machine, and the end of the arched cover 11 away from the hinged end is provided with a movable opening device.

[0027] In this example, the tea leaves are poured into the tea frying machine from the feeding port 10, and the openi...

Embodiment 2

[0029] see Figure 1~3 , a new type of tea frying machine, comprising a frame 1, the frame 1 is provided with a fried tea ball 7, and the outer ball walls on both sides of the middle part of the fried tea ball 7 are provided with a rotating shaft 3 parallel to the frame 1, The rotating shaft 3 runs through both sides of the frame 1; the rotating shaft 3 on one side of the fried tea ball 7 is provided with a motor 2, and the rotating shaft 3 on the other side of the fried tea ball 7 is provided with an anti-off cover 6; the fried tea ball 7 leans against the machine The spherical surface on one side of the frame 1 is provided with a feeding port 10, and the upper part of the feeding port 10 is provided with an arched cover 11 hinged on the tea frying machine, and the end of the arched cover 11 away from the hinged end is provided with a movable opening device.

[0030] The bottom of the frame 1 is provided with a stove placement cavity 4, and the stove placement cavity 4 is at ...

Embodiment 3

[0033] see Figure 1~3 , a new type of tea frying machine, comprising a frame 1, the frame 1 is provided with a fried tea ball 7, and the outer ball walls on both sides of the middle part of the fried tea ball 7 are provided with a rotating shaft 3 parallel to the frame 1, The rotating shaft 3 runs through both sides of the frame 1; the rotating shaft 3 on one side of the fried tea ball 7 is provided with a motor 2, and the rotating shaft 3 on the other side of the fried tea ball 7 is provided with an anti-off cover 6; the fried tea ball 7 leans against the machine The spherical surface on one side of the frame 1 is provided with a feeding port 10, and the upper part of the feeding port 10 is provided with an arched cover 11 hinged on the tea frying machine, and the end of the arched cover 11 away from the hinged end is provided with a movable opening device.

[0034] And the outside of the frame 1 that fixes the rotating shaft 3 is provided with a hook 5 . A hook 5 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com