Threshing device of agricultural grain combine harvesting equipment

A threshing device and grain technology, applied in agriculture, threshing equipment, agricultural machinery and implements, etc., can solve the problems of single rolling threshing pass, no drying function, etc., so as to avoid damage to grain and prevent overheating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

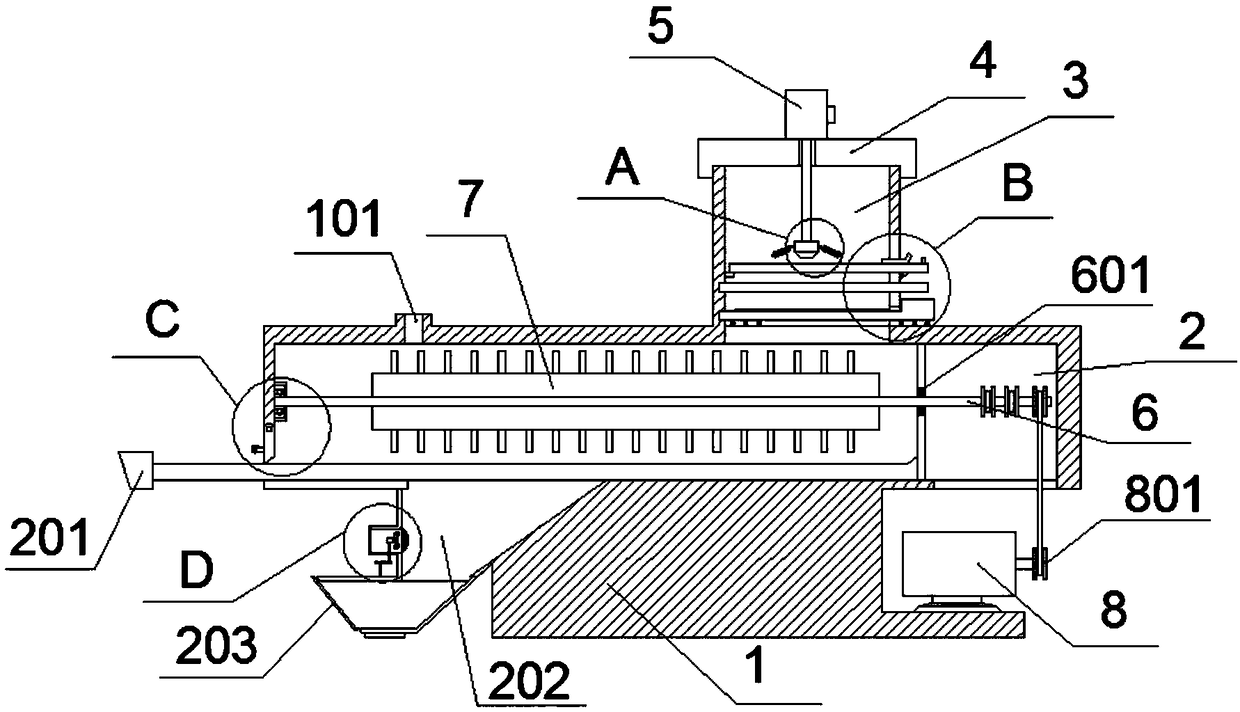

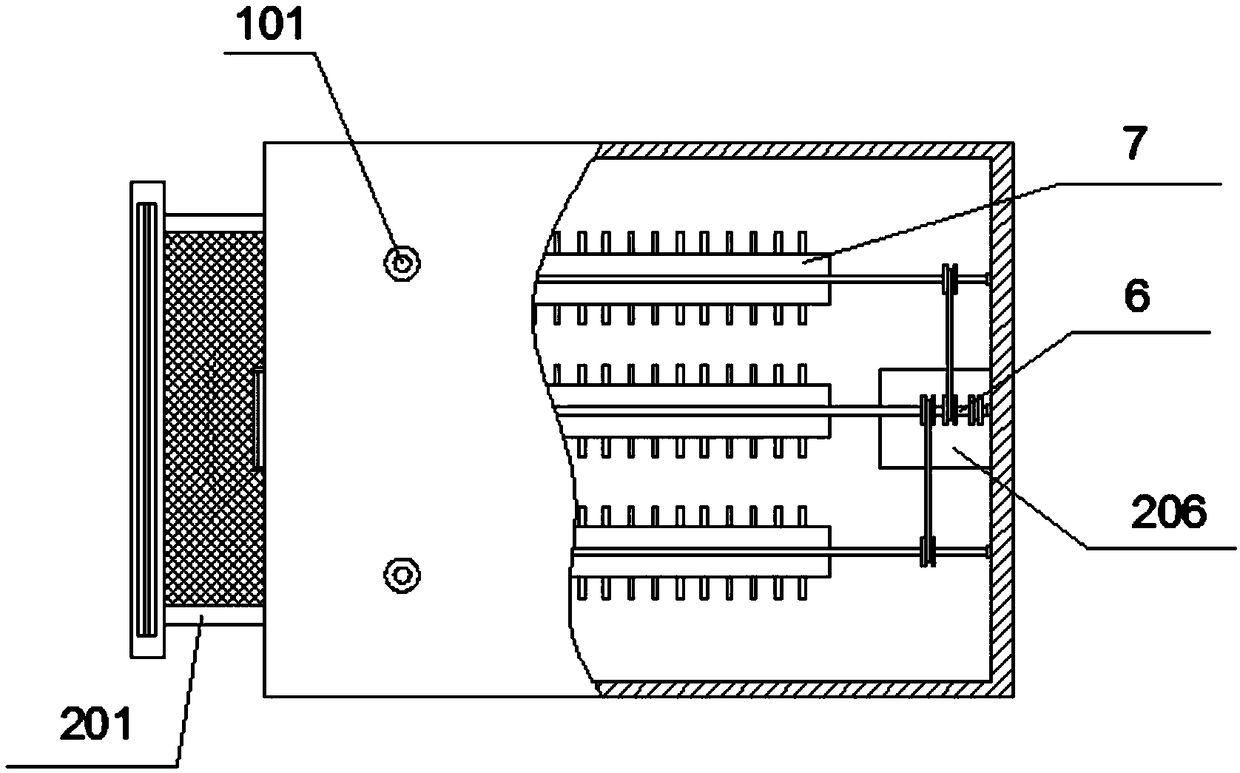

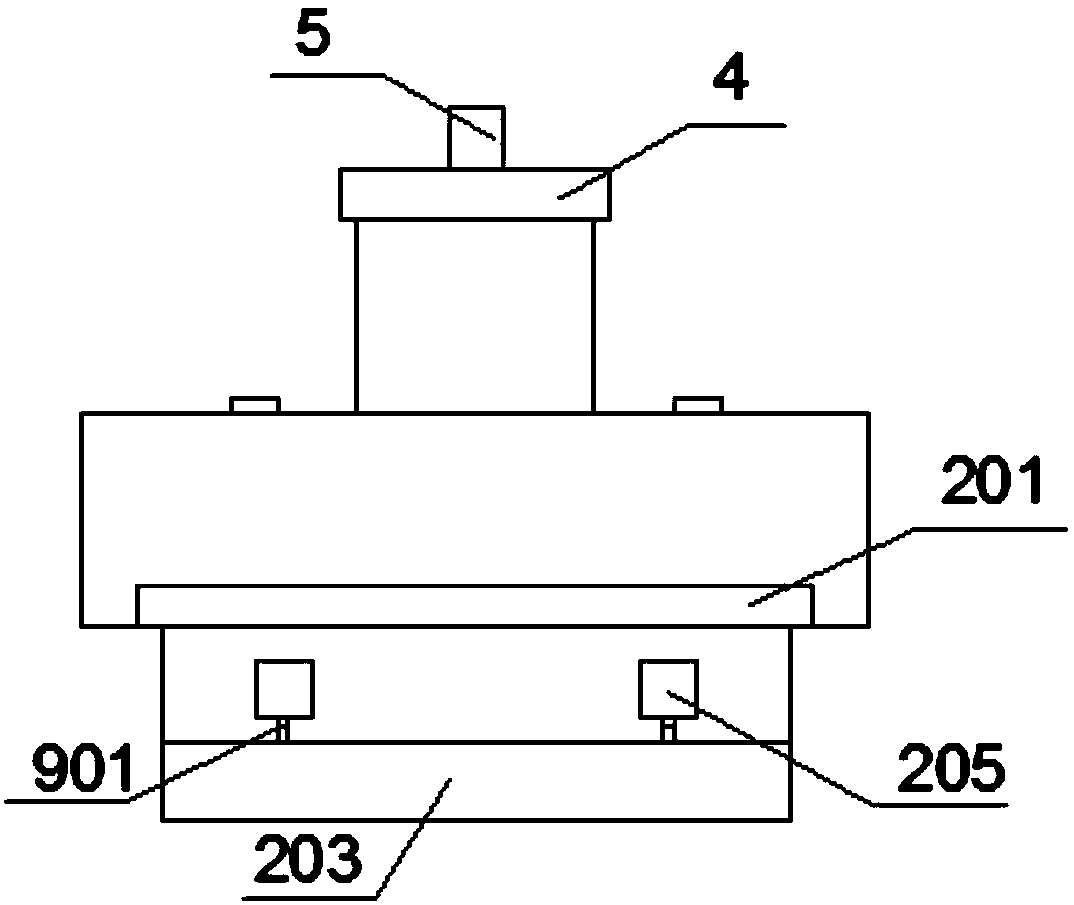

[0040] as attached figure 1 to attach Figure 9 Shown:

[0041] The present invention provides a threshing device for combined agricultural grain harvesting equipment, which includes a housing 1, an air vent 101, a movable baffle 102, a baffle handle 103, a threshing bin 2, a threshing plate 201, a screen A20101, a trapezoidal groove 20102, Threshing plate handle 20103, grain outlet 202, grain receiving plate 203, fan cylinder 204, ventilation plate 205, drying bin 3, heating plate 301, heating plate pulley 30101, control button 30102, heating wire 30103, power cord 30104, sieve Net B302, screen C303, screen C bottom baffle 30301, screen C top baffle 30302, screen C block 304, drying bin top cover 4, stirring motor 5, motor wheel 501, stirring bar 502, stirring Brush 503, threshing shaft 6, bearing A601, bearing B602, bearing sleeve 603, threshing roller 7, transmission motor 8, motor pulley 801, blower fan 9, telescopic rod 901, movable bolt 902, fan top block 903, fan fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com