A quick loading and unloading short-circuit clamp and its short-circuit method

A short-terminal clip and fast technology, applied in the field of power grid, can solve the problems of short-terminal clip high-altitude short-circuit time-consuming, shorten short-terminal operation time, and threaten the personal safety of operators, so as to achieve flexible combination and replacement, reduce Threat to personal safety, effect of improving safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

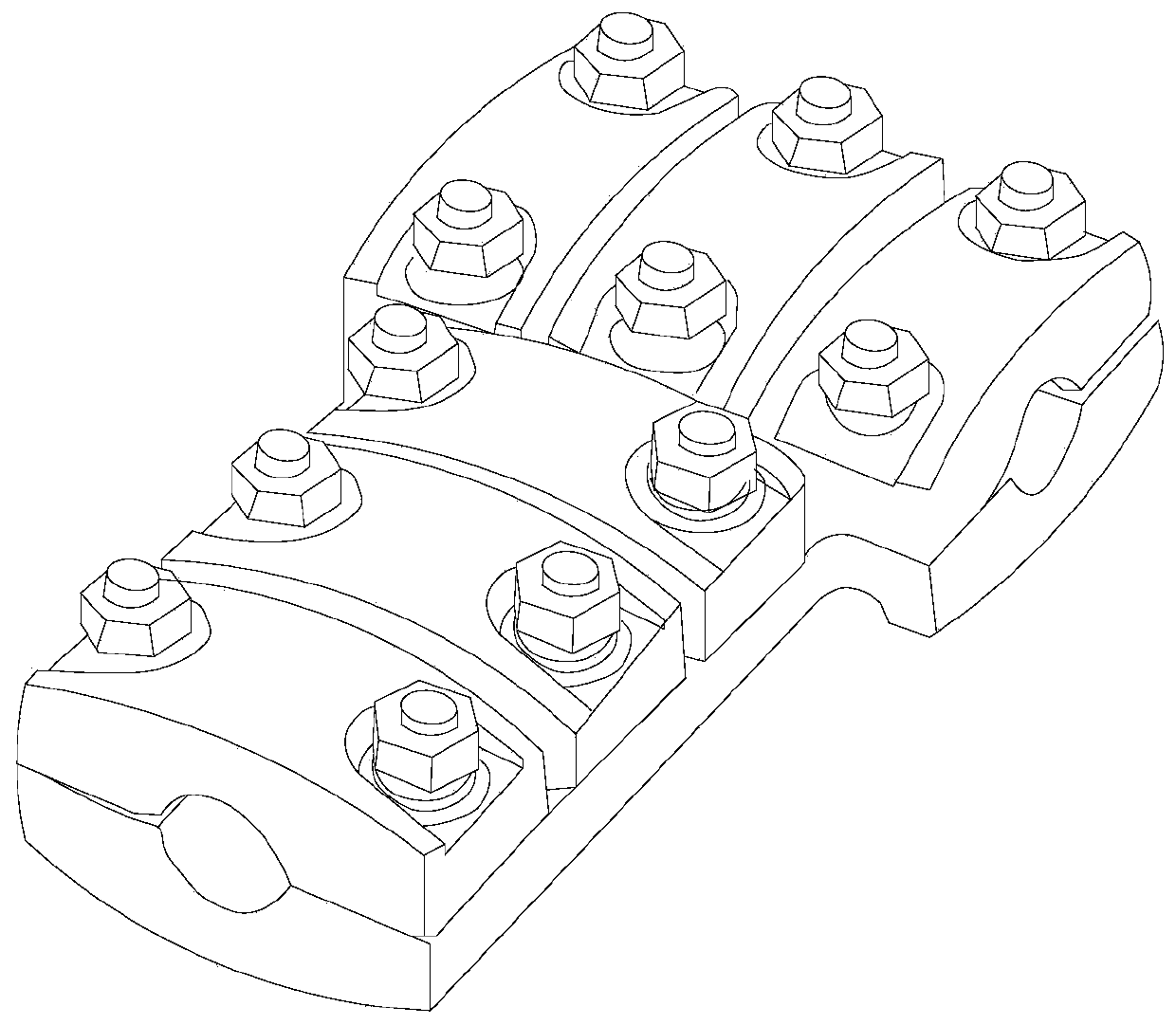

[0033] A quick-release short-terminal clamp, such as Figure 2 to Figure 5 As shown, it includes a bottom cover 1, the first wire groove 2 with both ends open is arranged on the bottom cover 1, and several side-by-side glands 3 are hinged on the bottom cover 1 through the connecting shaft 18, and the surface of the gland 3 is arranged The second wire groove 4 with both ends open, the second wire groove 4 and the first wire groove 2 are facing each other, the long axis of the second wire groove 4 is parallel to the long axis of the first wire groove 2, and the One end of the gland 3 away from the connecting shaft 18 is fixedly connected to the mounting plate 5, the mounting plate 5 is provided with a through hole 6, and the two ends of the mounting plate 5 along the long axis direction of the second wire groove 4 are facing a limit Flange 7, the limit flange 7 is fixedly connected with the bottom cover 1, the side surface of the limit flange 7 facing away from the direction whe...

Embodiment 2

[0036] A quick-loading and dismounting short-terminal clip. On the basis of Embodiment 1, a number of first hinge seats 12 are provided at the end of the bottom cover 1 away from the direction where the limit flange 7 is located. The first hinge seats 12 are connected to the The limit flanges 7 are facing one by one; two second hinge seats 13 are provided at the end of the gland 3 away from the direction where the mounting plate 5 is located, and shaft holes are provided on the first hinge seat 12 and the second hinge seat 13 14 ; the connecting shaft 18 passes through all the shaft holes 14 on the first hinge base 12 and the second hinge base 13 . One end of the connecting shaft 18 is provided with a plug 15 and the other end is provided with a cotter pin 16 . The cross-sections of the first wire groove 2 and the second wire groove 4 are arc-shaped with equal radii. The inner walls of the first wire groove 2 and the second wire groove 4 are provided with anti-slip lines para...

Embodiment 3

[0038] A quick-loading and dismounting short-terminal clamp, as attached Figure 6 As shown, on the basis of any of the above embodiments, the mounting plate 5 is provided with a notch 17 communicating with the through hole 6 , and the notch 17 is located on the side of the mounting plate 5 away from the connecting shaft 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com