Thermal processing device for built-in circuit board of single-fiber bidirectional optical transceiver module

An optical transceiver module and single-fiber bidirectional technology, which is applied in the direction of assembling printed circuits, printed circuits, and printed circuit manufacturing of electrical components, and can solve the limitations of equipment quantity, working hours, and positioning methods, increase enterprise labor costs, and increase the number of employees. problems, to achieve the effect of ensuring stability, prolonging service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

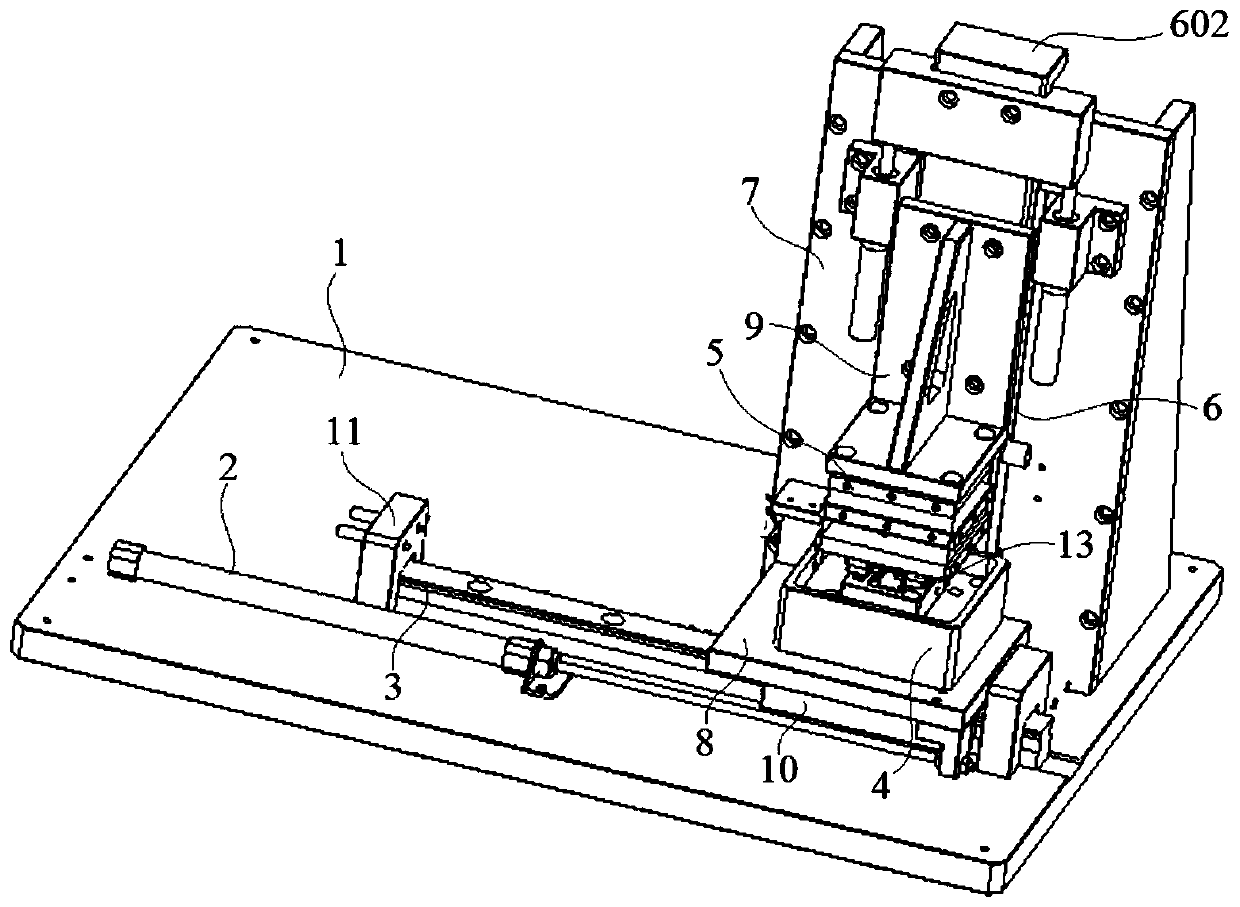

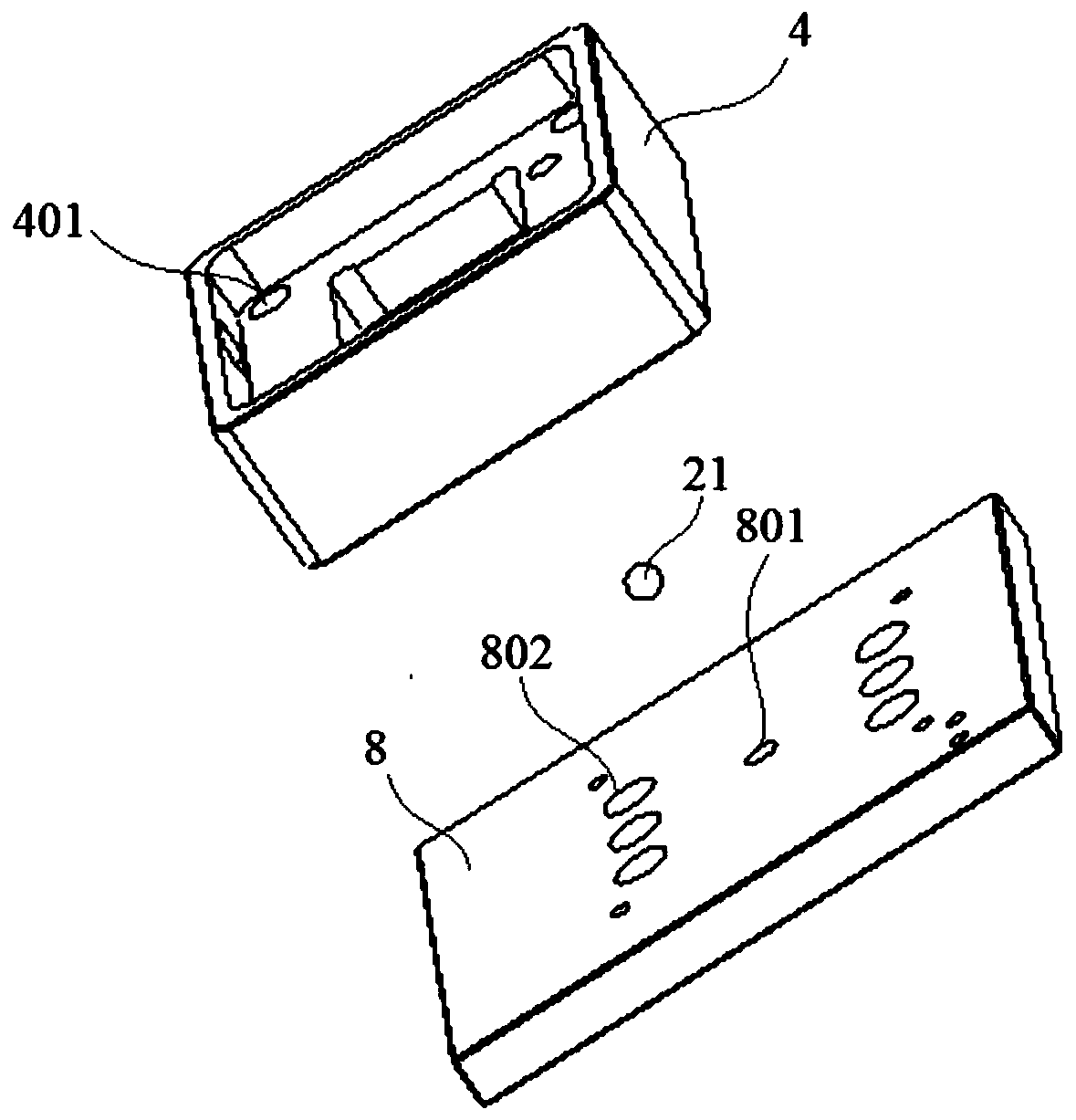

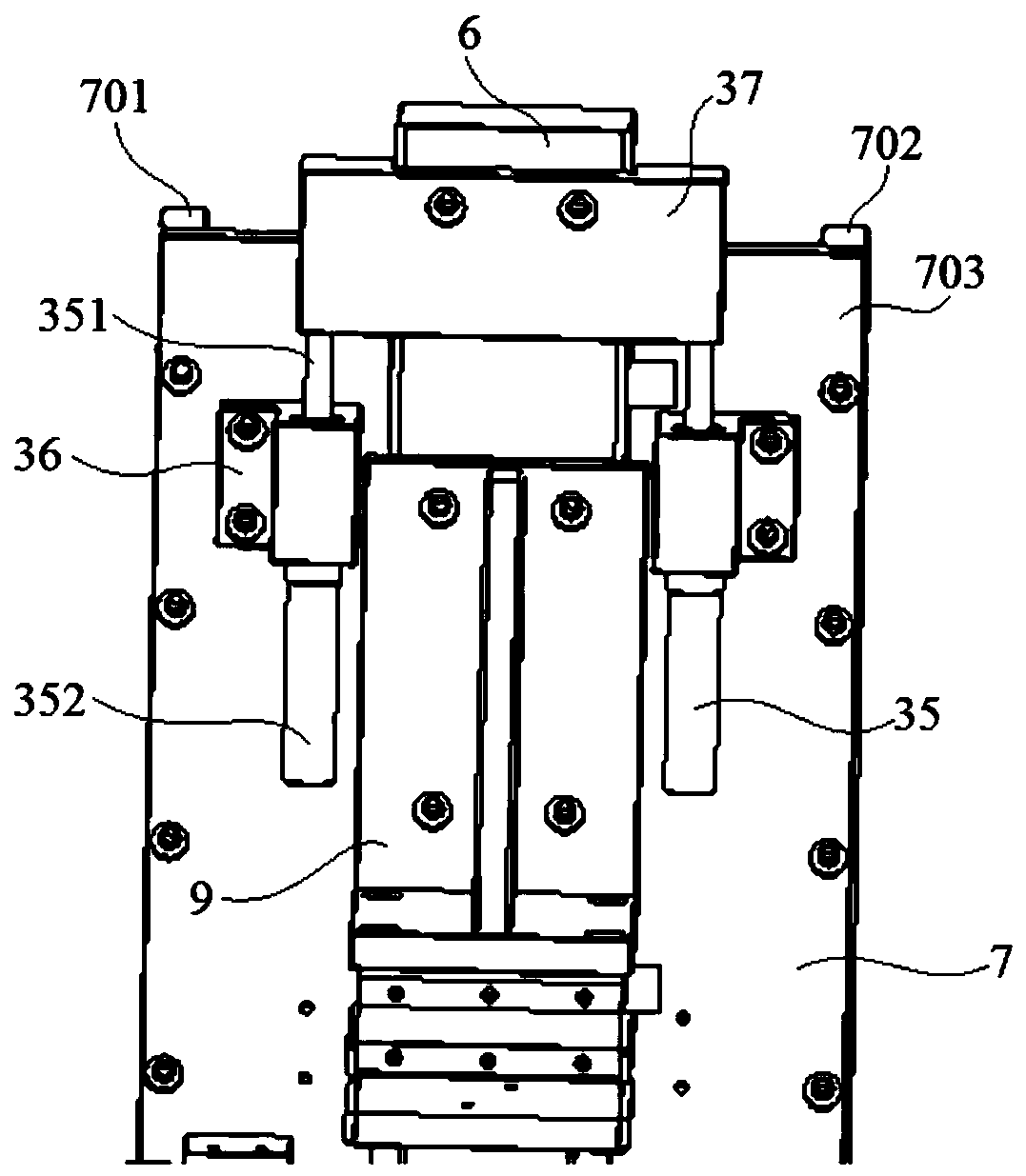

[0026] Embodiment 1: A thermal processing device for a built-in circuit board of a single-fiber bidirectional optical transceiver module, including a base plate 1, a horizontal cylinder 2, a slide rail 3, a lower pressure seat 4, an upper pressure plate 5, a vertical cylinder 6 and a mounting frame 7. The horizontal cylinder 2 and the slide rail 3 are installed in parallel on the upper surface of the base plate 1, the lower pressure seat 4 is movably installed on the slide rail 3 through a movable plate 8, and the mounting frame 7 is installed on the upper surface of the base plate 1, The fixed part of the vertical cylinder 6 is fixedly installed on the outer surface of the mounting frame 7, and the upper pressing plate 5 is fixedly connected with the movable part 602 of the vertical cylinder 6 through a connecting plate 9;

[0027] An indenter 13 is arranged below the upper platen 5, and the side surface of the indenter 13 is provided with a plurality of through holes for the ...

Embodiment 2

[0032] Embodiment 2: A thermal processing device for a built-in circuit board of a single-fiber bidirectional optical transceiver module, including a base plate 1, a horizontal cylinder 2, a slide rail 3, a lower pressure seat 4, an upper pressure plate 5, a vertical cylinder 6 and a mounting frame 7. The horizontal cylinder 2 and the slide rail 3 are installed in parallel on the upper surface of the base plate 1, the lower pressure seat 4 is movably installed on the slide rail 3 through a movable plate 8, and the mounting frame 7 is installed on the upper surface of the base plate 1, The fixed part of the vertical cylinder 6 is fixedly installed on the outer surface of the mounting frame 7, and the upper pressing plate 5 is fixedly connected with the movable part 602 of the vertical cylinder 6 through a connecting plate 9;

[0033] An indenter 13 is arranged below the upper platen 5, and the side surface of the indenter 13 is provided with a plurality of through holes for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com