A detonation control method for reducing blasting vibration

A control method and blasting vibration technology, which is applied in the field of blasting, can solve problems such as difficulty in undertaking large-scale blasting projects, slow construction progress, and low reliability of blasting transmission networks, so as to reduce blasting vibration effects and speed up blasting construction progress , Improve the effect of blasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

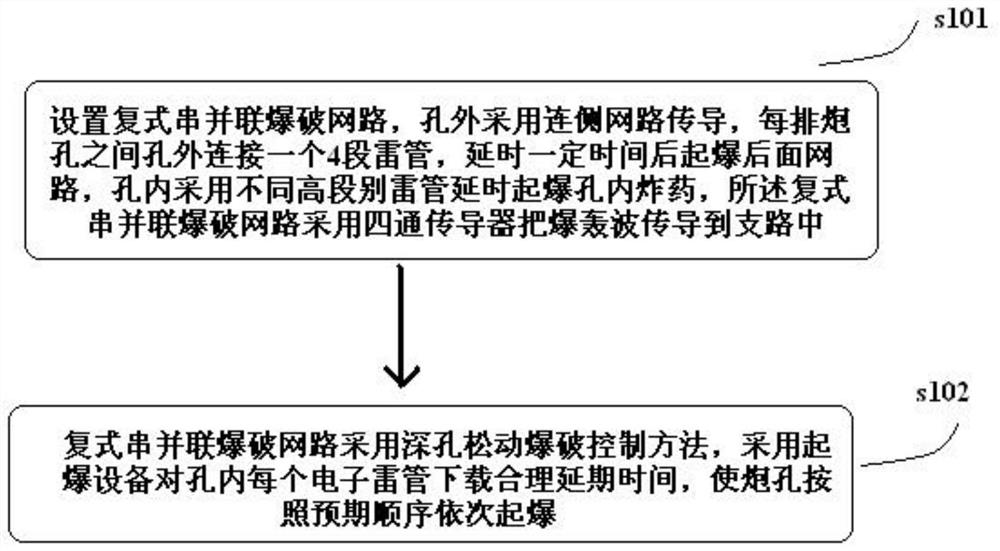

[0024] see figure 1 , the detonation control method for reducing blasting vibration includes steps:

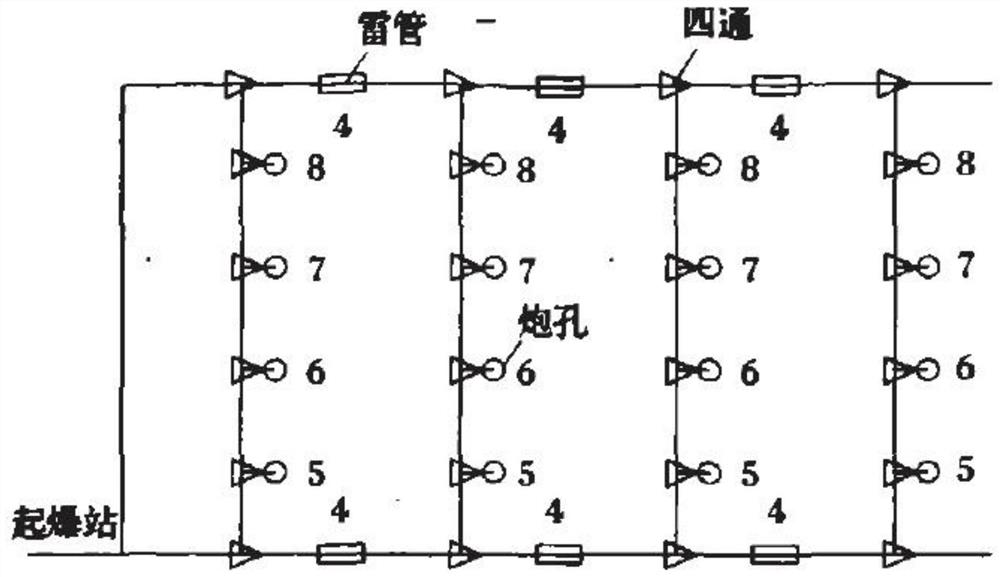

[0025] S101, setting up a duplex series-parallel blasting network, see figure 2 , the side network conduction is used outside the hole, and a 4-stage detonator is connected outside the hole between each row of blastholes, and the rear network is detonated after a certain period of time. The compound series-parallel blasting network uses a four-way conductor to conduct the detonation wave into the branch;

[0026] S102, the compound series-parallel blasting network adopts the deep hole loosening blasting control method, and uses the blasting equipment to set a reasonable delay time for each electronic detonator in the hole, so that the blast holes are detonated in sequence according to the expected sequence.

[0027] figure 2 The blasting network is designed to better control the hazards of blasting vibration, ensure the safety of buildings, reduce the amount of single-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com