Air-source water heater and defrosting method thereof

An air source water heater and compressed air technology, applied in fluid heaters, lighting and heating equipment, damage protection, etc., can solve problems such as inability to guarantee hot water supply, low and incomplete defrosting efficiency, and improve defrosting efficiency , high defrosting efficiency, and the effect of reducing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

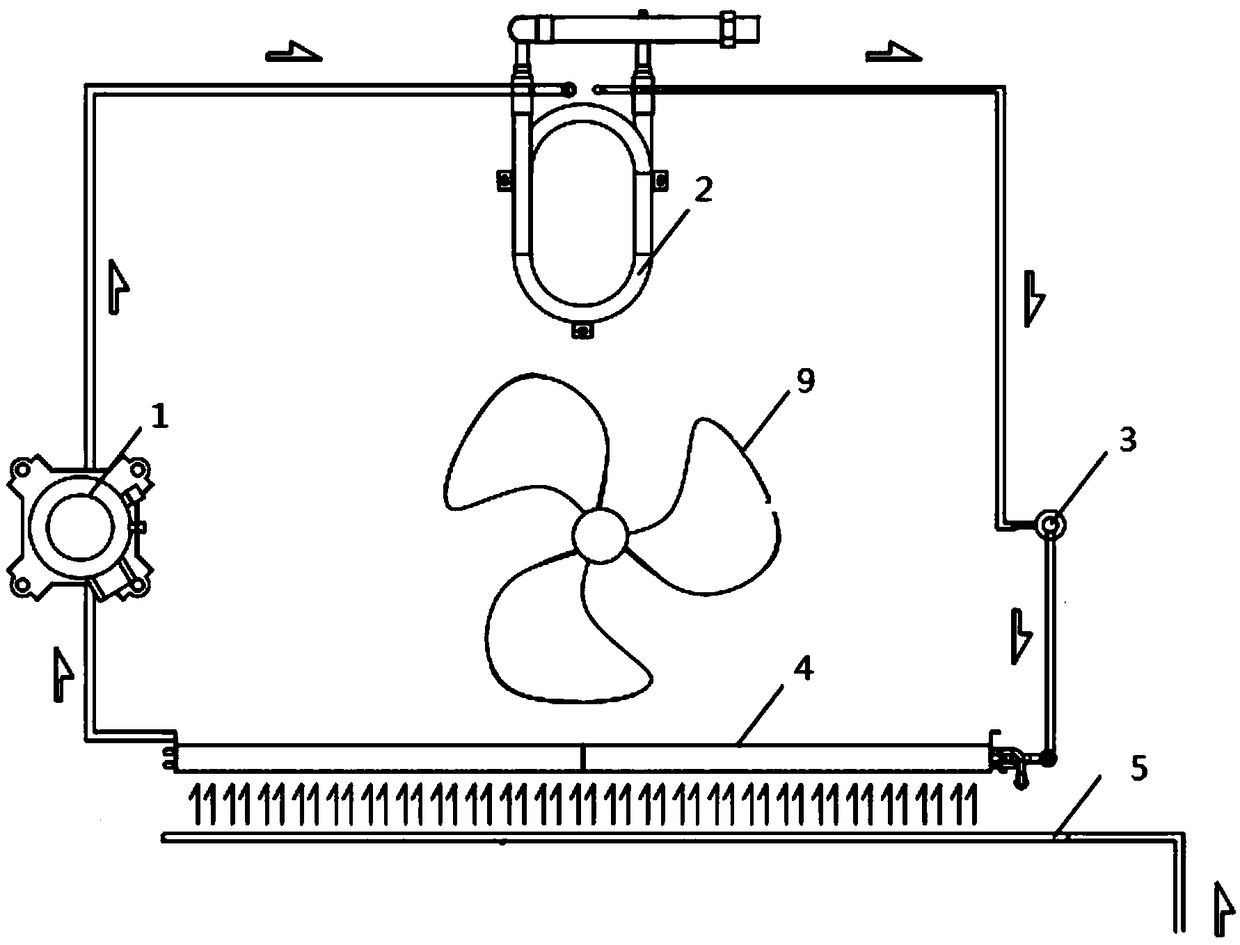

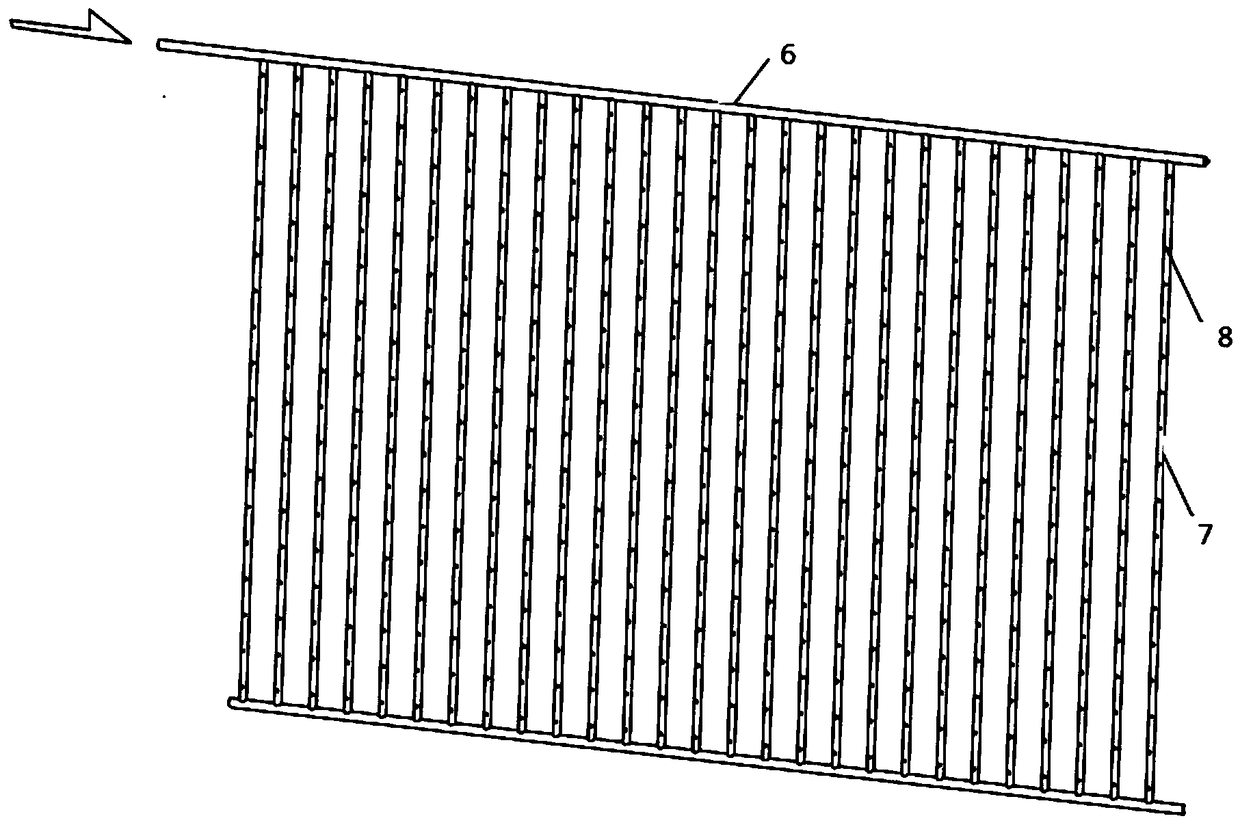

[0032] Such as figure 1 and 2 A specific implementation of the air source water heater shown includes: a compression cycle pipeline, including a compressor 1, a condenser 2, a throttle valve 3 and an evaporator 4 connected in sequence, and the outlet of the evaporator 4 is connected to the The inlet of the compressor 1; the defrosting device, which is arranged on one side of the evaporator 4, is stored inside for blowing air to the surface of the evaporator 4, so as to provide the defrosting of the surface of the evaporator 4. Compressed air for heat and power. Among them, the compressor 1 converts the low-temperature and low-pressure refrigerant gas absorbed from the evaporator 4 into a high-temperature and high-pressure refrigerant gas by doing work, thereby obtaining energy for exchanging heat with the equipment in the compression cycle line; the condenser 2 Used for heat exchange between the high-temperature and high-pressure refrigerant gas flowing out of the compressor...

specific Embodiment approach

[0041] A specific embodiment of a defrosting method for an air source water heater, comprising:

[0042] S1: monitoring the first temperature outside the compression cycle pipeline and the second temperature inside the evaporator 4 in real time;

[0043] S2: When the first temperature is less than the first preset value and the second temperature is less than the second preset value, compare the difference between the first temperature and the second temperature with the third preset value, and when When the difference is greater than the third preset value, and the interval time reaches the first predetermined time, the defrosting device is controlled to open, and the surface of the evaporator 4 is blown and defrosted until the second temperature When the fourth preset value is reached or the blowing and defrosting time reaches the second predetermined time, the blowing and defrosting is stopped, wherein the fourth preset value is greater than the second preset value; as long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com