Prefabricated drainage prestressed anti-slide pile structure and construction process thereof

A prestressed, anti-sliding pile technology, applied in the direction of foundation structure engineering, soil protection, excavation, etc., can solve the problem that the anti-sliding pile structure is not suitable for gradual damage or accelerated damage to landslide disasters, so as to improve the stability of the landslide, enhance the Shear resistance, effect of increasing shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

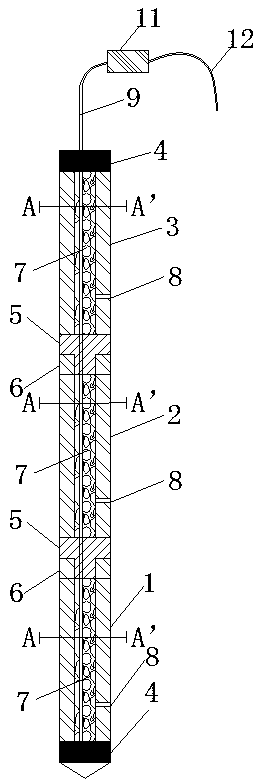

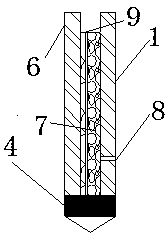

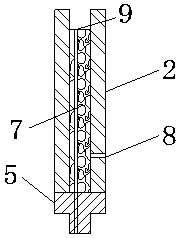

[0039] An assembled drainage prestressed anti-sliding pile structure, comprising a pipe pile, the pipe pile is provided with prestressed tendons 10, the pipe pile is provided with a pipe pile inner hole, the pipe pile inner hole is filled with gravel 7, and the upper diameter of the pipe pile is A water filter hole 8 is provided, the water filter hole 8 runs through the wall of the pipe pile and communicates with the inner hole of the pipe pile, and a drainage pipe 9 penetrates into the inner hole of the pipe pile. The pipe piles include sequentially connected type I steel concrete pipe pile 1, type II steel concrete pipe pile 2 and type III steel concrete pipe pile 3, the bottom of type I steel concrete pipe pile 1 is provided with a terminal plate 4, and the upper end is provided with There are connecting end plates 6, type II steel concrete pipe pile 2 is provided with threaded end plate 5 at the lower end, and connecting end plate 6 at the upper end, and type III steel stru...

Embodiment 2

[0060] The present embodiment further illustrates the present invention in conjunction with accompanying drawing, as figure 1 Shown:

[0061] The invention is suitable for landslide disaster rapid control projects or emergency rescue projects in gradual damage or accelerated damage.

[0062] The prefabricated drainage prestressed anti-slide pile structure consists of type I steel concrete pipe pile 1, type II steel concrete pipe pile 2, type III steel concrete pipe pile 3, end plate 4, threaded end plate 5, connecting end plate 6, broken Stone 7, filter hole 8, drainage pipe 9, prestressed tendon 10, water pump 11, water delivery pipe 12 constitute.

[0063] Type I steel concrete pipe pile 1 length l 1 2-3m, the outer diameter (pile diameter) is d , generally 30-80cm, the inner diameter is d 0 , generally 10-30cm, a plurality of anchor cable holes are evenly opened in the thick wall of type I steel concrete pipe pile 1, which is convenient for the threading of prestresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com