Organic waste gas adsorption and desorption box body

A technology of adsorption and desorption, organic waste gas, applied in gas treatment, membrane technology, separation of dispersed particles, etc., can solve the problems of high power consumption of main fan, reducing wind speed, and high operating noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

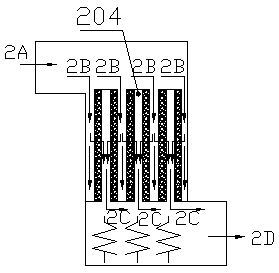

[0028] image 3 It is an isometric view of the organic waste gas adsorption and desorption box of the present invention. For the convenience of observation and description, the door is hidden in the view. The organic waste gas adsorption and desorption box of the present invention is mainly composed of a housing 301, an adsorption material container 302, and an adsorption material container. The absorbing material container 303 is connected to the housing 301 by welding, and the absorbing material container 302 is placed flat on the absorbing material container 303.

[0029] The housing 301 functions to isolate and seal the outside world, and can also support the adsorption material container 302 and the adsorption material container holder 303.

[0030] Figure 4 It is an axonometric drawing of the adsorbent container holder. The adsorbent container holder consists of a frame, a supporting beam 404 (10 pieces in the figure), a U-shaped groove 403 (10 pieces in the left-right direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com